Fred Mills, BSc, BS, SD (Hons) said:

My only suggestion on “Good, derailment-proof track” begins with, not the track itself, but the roadbed. Your track is only as good as your roadbed.

As far as Kadee couplers; the “Uncoupling tails or simulated air hoses” are in 99% of the couplers, at the correct height, its only if you don’t have the couplers properly mounted at the correct height, that you have any problems…use a Kadee height gauge…or make one for yourself, but if you do make one; MAKE SURE it is spot on…AND USE THE BLOODY THING ON EVERY CAR.

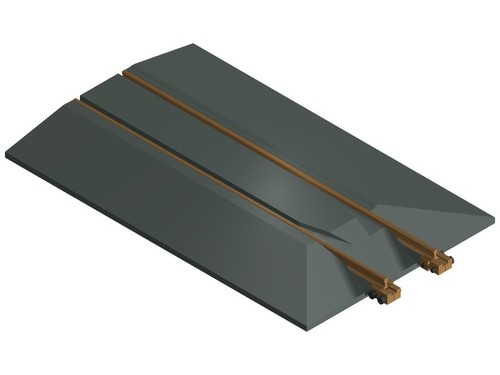

Some are suggesting “Extra rails inside the stock rails”. These are just like the real railroads use on bridges. THEY ARE CALLED “Guard Rails”, and can also be found often on sharp curves.

Another factor, that doesn’t usually cause problems on regular track, is WHEEL GAUGE. Usually it causes derailments at switches. CHECK THE BACK-TO-BACK WHEEL GAUGE ON EVERY WHEEL SET…the Aristocraft wheel/track gauge works well, if you can find one.

I have been in the practice of checking the wheel gauge, on every car while converting to Kadee couplers, BEFORE any car goes into service. This has provided us with ALMOST derailment free/FRUSTRATION free operations on the IPP&W. Most of the few derailments we experience are caused by operator error, or crap on the track.

Tunnels are something that real railroads avoid if at all possible. On a model railroad, avoid them too, but if you must have any; make them short, or provide easy access, because, if a derailment is going to happen; sure enough it will be just where you can’t reach it. Something like “Murphy’s Law”…it is also the home of choice for most ground dwelling creatures, that soon lay down laws of ownership…!!

Yes Fred, I do have and use a KaDee coupler height gauge. I also have a 1/8 piece of wood that I use to check the coupler trip pins, and the pins are usually a bit low. This is my experience, you mileage may vary.

Every car is run through the shop before it rides the rails here on the P&CS. Plastic wheels are replaced with metal wheels. All wheels are checked for proper gauge, and for wobble. The wheels are also checked to make sure they roll free and the trucks are checked to make sure they can swivel and at least one per car can rock a little. Kadees are mounted and checked for height and the trip pin is also checked. The KaDees are also checked to make sure they swing properly and self center.

A few years back I did an inspection of all my rolling stock. This was done a few cars a day for most of the summer. I found wheels that were binding, usually because a blade of grass was caught between the axle and the journal. I found a few droopy couplers, and one car with Aristo wheels in one truck and USA wheels in the other truck. I think there is a bad order form in the file to explain how that happened, I haven’t checked to see.

Properly set up rolling stock, on decent track-work, doesn’t derail all that frequently. So when I do have a derailment I am surprised, and like you said, its usually something on the track.

Tunnels are interesting visual features, and I understand why people would want one. But I ripped mine out after only a few years, because it had issues. So I would think carefully about wanting a tunnel. Some folks don’t have any problems with theirs, other folks do have problems. Now about the track with limited access, that you have to try and work around, or work with.