Dave Taylor said:… our CMO Tom Artzberger was, from scratch, building the new light.

Is scratchbuilding easier in that scale or in G?

Expect that painting numberboards certainly is easier in that scale than G.

Dave Taylor said:… our CMO Tom Artzberger was, from scratch, building the new light.

Is scratchbuilding easier in that scale or in G?

Expect that painting numberboards certainly is easier in that scale than G.

Forrest… Well there are a number of real differences … Working on the 1:1 version can be incredibly dirty… I mean really really greasy Grimy, coal sootty, dirty… And if something just almost fits, but not quite, we can use a BFH to make it fit… not an option in 1:20. We get to use MIG and TIG welders, never yet seen any G something welded with 3/16 sticks…

BUT in 1;20 I can bring it indoors out of the weather and into the warmth to fix… And the list goes on and on… Oh… and there ain’t no 10ft rule on the real thing, and rivet counters are for real…

Dave

Dave Taylor said: Oh… and there ain’t no 10ft rule on the real thing, and rivet counters are for real…

Hehehe! and I’ll bet some “rivet counting” is even Federally mandated.

That brings to mind another G scale good thing, nobody says I Have To take it all apart every thousand days or so.

Well the feds do give us a bit more time to count all the rivets, 1472 days or 15 years,… 315’s 1472 comes due in 2022. we are scheduling to re-build her in the winter of 21-22.

we are hoping to raise 100K to keep her running.

Dave

Onto todays fun…

The wooden mockup, or movie prop of a wooden cow catcher I made to be used when we backdate 315 to her 425 years, Has a clearance issue, when trying to couple to the C&TS’s standard gage knuckles on the rear of their tenders. This is caused by 315/425 not having the age specific coupler box and the long shank knuckles that were in use then to extend the knuckle out over the cow catcher for clearance on the extended and pointy cow catcher. We have looked for the correct set up, but none to be found as most all these were removed over 100 years ago ( 1917 ) and new shorter styled ones used.

To overcome this clearance issue with the drop pin on the large knuckles, I’m going to have to cut down the area of the front bars to make room.

We need 4" cut down to clear, but I’m gonna cut 5 1/2" to be sure. Note the cut mark on the center bars.

Note that this will remove the back bracing for the center bars. I’ll have to come up with something new to support.

And some cut marks. Now to figure out how to cut those down… Recipt Saber saw with a long blade seems like the best bet.

Stay tuned as the newest adventure continues…

Dave.

Got some time to work on the cowcatcher today…

Started by cutting thru the bars;

And then cut the support bar loose.

Cut a piece of 2 x 12 to fit in-between the long bars, and then marked the locations of the cut down bars to dado out.

So onward for tomorrow…

Stay tuned

Jumping around on projects here. On the Headlight Number boards. On the first board that I did ( kinda a test). I painted the white backing with a couple of coats of rattle can white, After drying and all I laid it on my light table and it wasn’t as bright or translucent as I had hoped for.

On the remaining two boards I looked into several things that would give better illuminance, such as mylar, vinyl and such. I didn’t think it gave much improvement.

So I just gave them a very light coat of white, almost like a frosting. Outer two the new ones, inner the original.

There really is a considerable difference in the light transmission.

Doesn’t show up well. Laying on my light table, but L is the old one, R is the new one.

They will have to work. The headlight was dropped off to the pinstriper today for a bit of dress up.

Stay tuned.

Dave, Just curiosity here, but wouldn’t etching the glass give you the white appearance for the letters? Sometimes called frosted glass.

https://www.amazon.com/Armour-Etch-15-0200-Cream-10-Ounce/dp/B001BE3UM4

Dave,

I was involved in doing this for a diesel recently. they had a milk glass piece in the sandwich, so I cut the vinyl numbers out, and the vinyl was placed in the sandwich, making future changes easy, and no issues with illumination.

AL P.

Al. We had talked about doing just that, but were concerned with leaving the vinyl in the mix, because the heat build up in the lamp, both from the heat of the Smokebox, close proximity to the stack, and the 2 bulbs inside the light. So we chose to use the mask and paint. I wish that I had thought of the milk or opal glass before I hit it with the white paint.

Oh well it will have to do for now… but I’ll quickly be in the market for milk glass if the white fails… Thanks for the tip.

@ Dave M… we are using Acrylic panels, and I don’t know if that stuff will work on it. We did discuss abrading the acrylic but didn’t know how to get just the numbers, with out using yet another set of reverse masking. I did try a layer of frosted vinyl on the back, but we decided that it would have the same heat issues.

Stay tuned

For the Future Reference file. If you want to simulate frosted acrylic but don’t have any; run a Random Orbit sander with fine (220 or finer) paper on the back side for a pretty nice effect. Haven’t tried it back-lit yet; so I’m not sure how well it transmits light. Then you could mask the front with paint mask numbers and paint the outside black. Not easily changeable as Al’s idea is; but it’s not like 315 had more than a few numbers over it’s lifetime.

Well Not my weekend…Yesterday Friday the 13th, I lost all my emails and their backup from my server… Wiped clean, All gone along with all the attachments… AAArrrggggg!

So I started to get some work on the cow catcher… And just par for the course of things… I F’’'ing broke it… Right down the middle.

It split right thru the heart wood, clean thru…

Fustrated, I quit for the day… I think I need some TitebondIII, some clamps and a dozen pocket hole screws… Not today…

Adult beverage time sounds better…

Dave

I hate when that happens …

Well Dave,

This is why you can’t have nice things! .jpg)

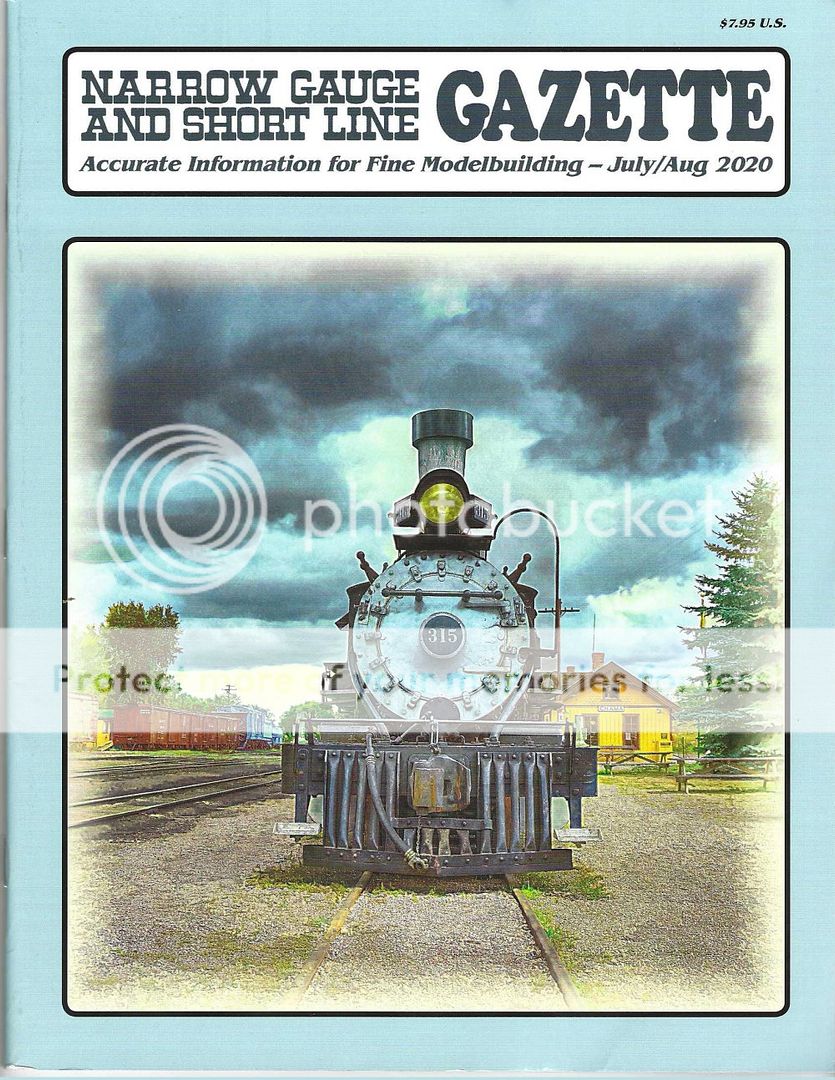

Dave’s baby made the cover of NG&SLG:

(https://i253.photobucket.com/albums/hh58/rgseng/DRGW315a_zpskoazuuhf.jpg)

Update time… We (the Board Of Directors for DRHS) finally got our agreement with the C&T signed and sealed, for the 1472 inspection and work to keep 315 alive for another 15 years…

Article in Trains Mag.

Really BIG thing to be able to keep her running.

Dave T.