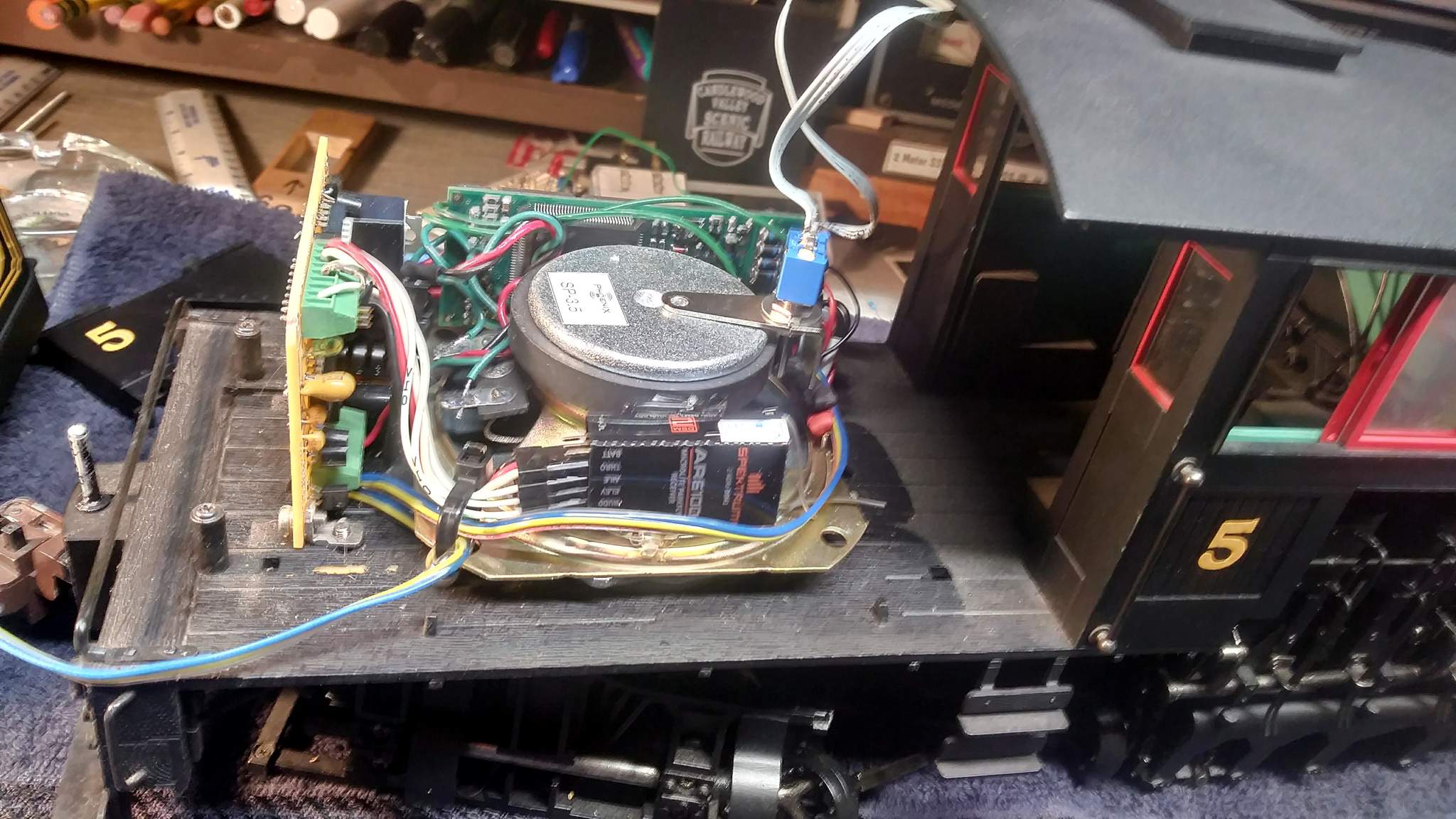

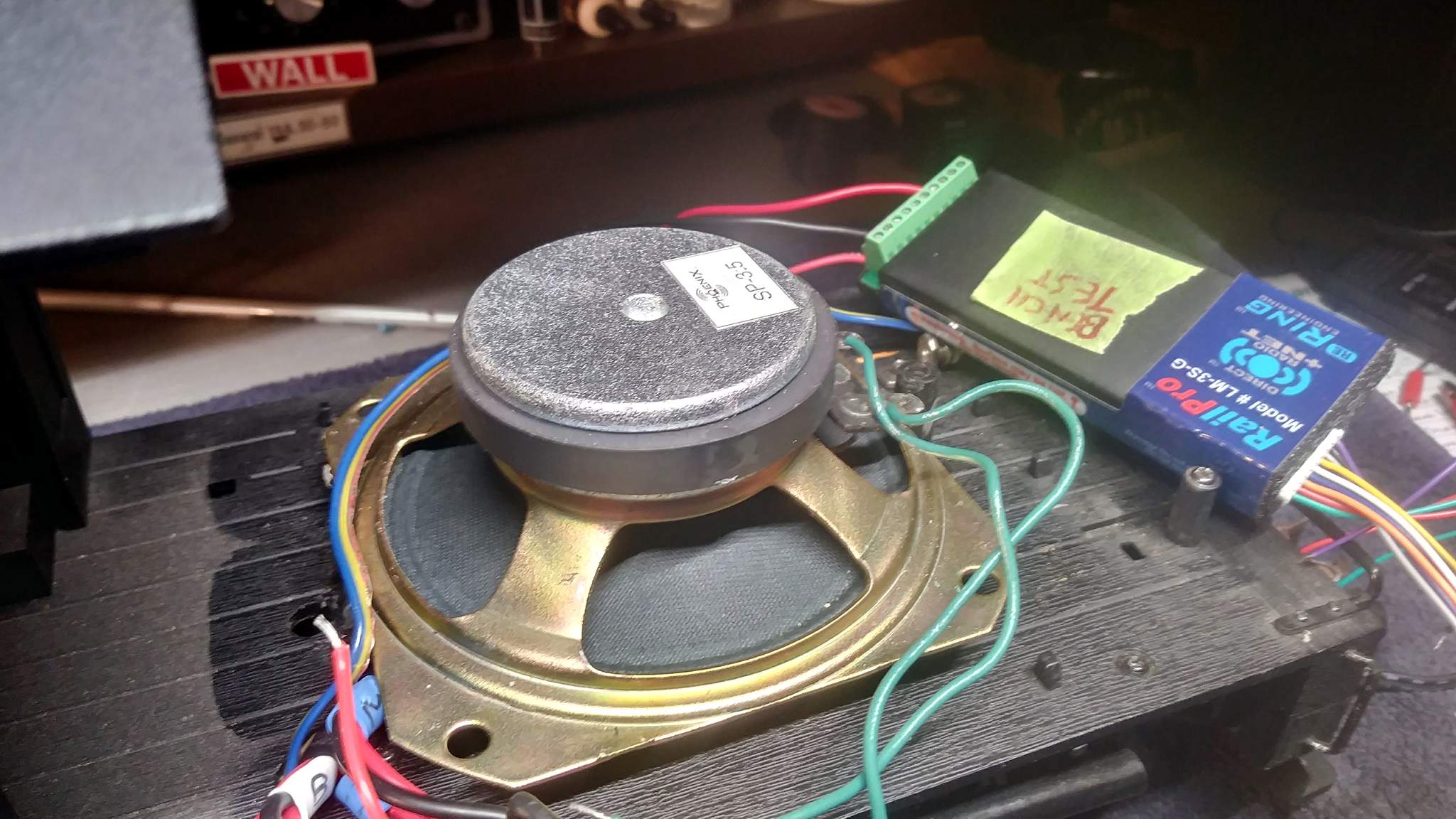

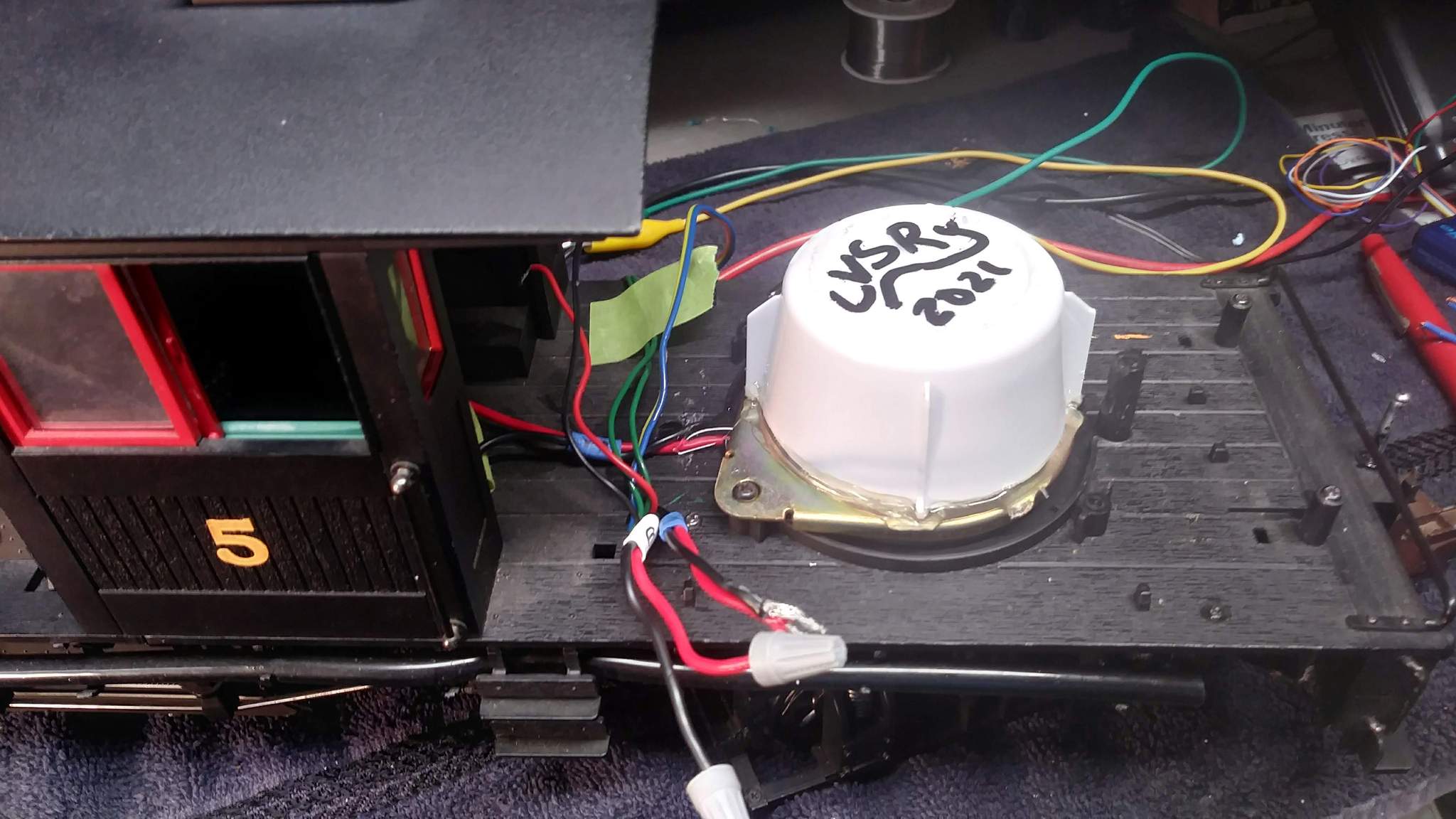

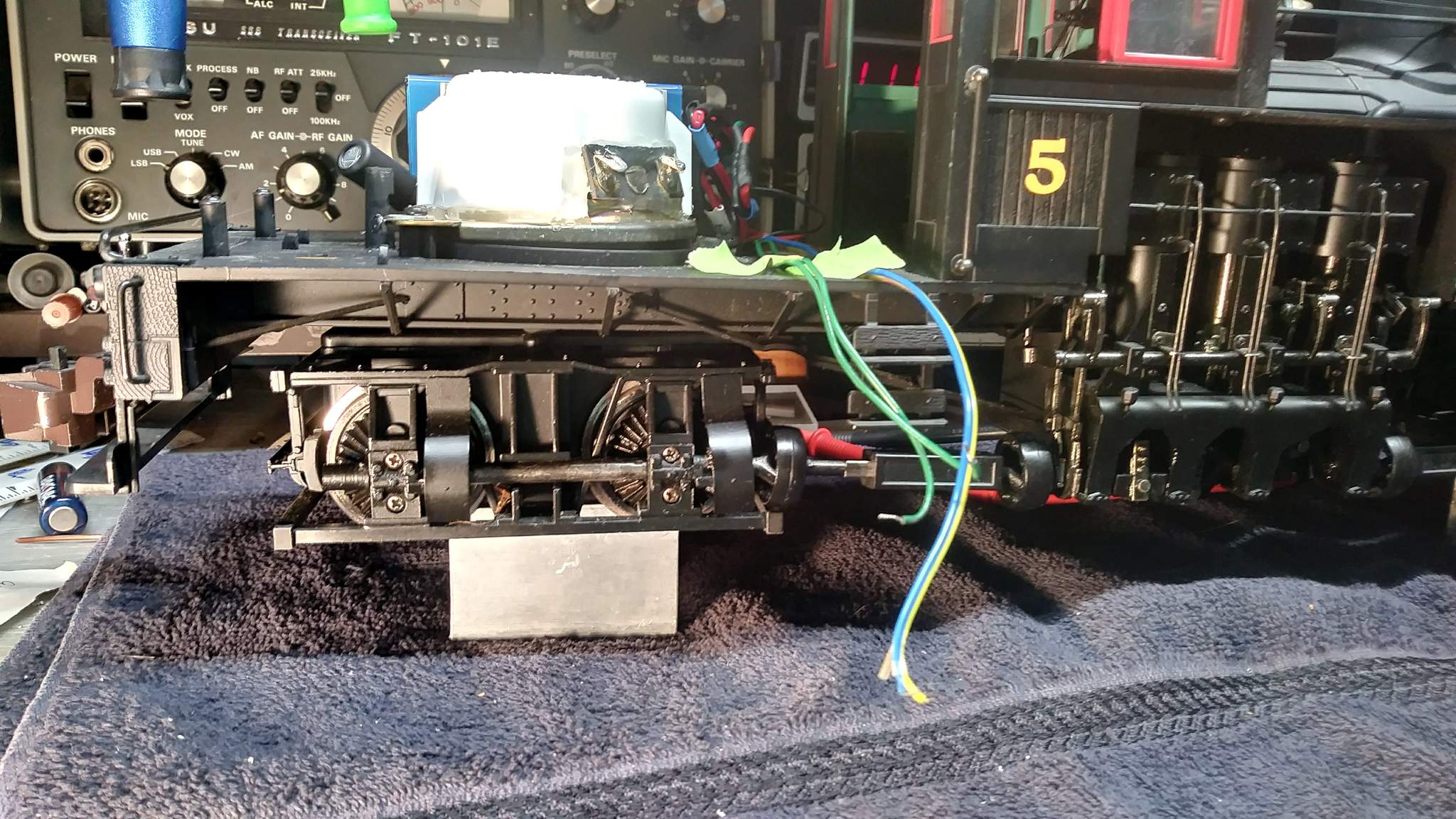

Today the railroad dragged (literally as Bachmann Shays will not free-wheel) Shay #5 off a storage track where it has sat since it somehow lost it’s link with my old 2-stick transmitter. In order to fix the link I would need to open it up, so I might as well convert it to RailPro while it’s open.

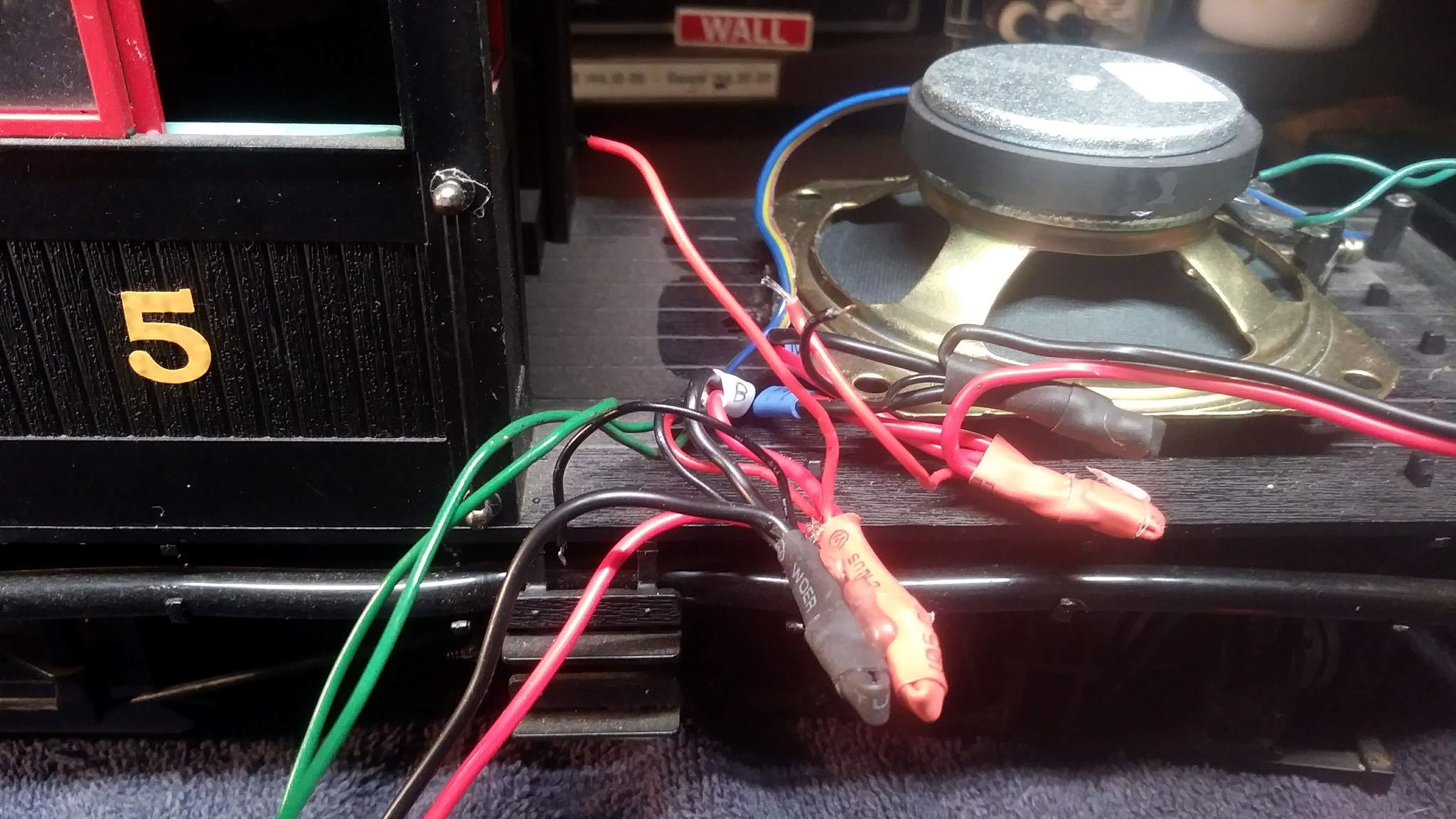

I managed to locate the wiring diagram from when I restored it and installed Battery/RC so I won’t need to reverse engineer anything.

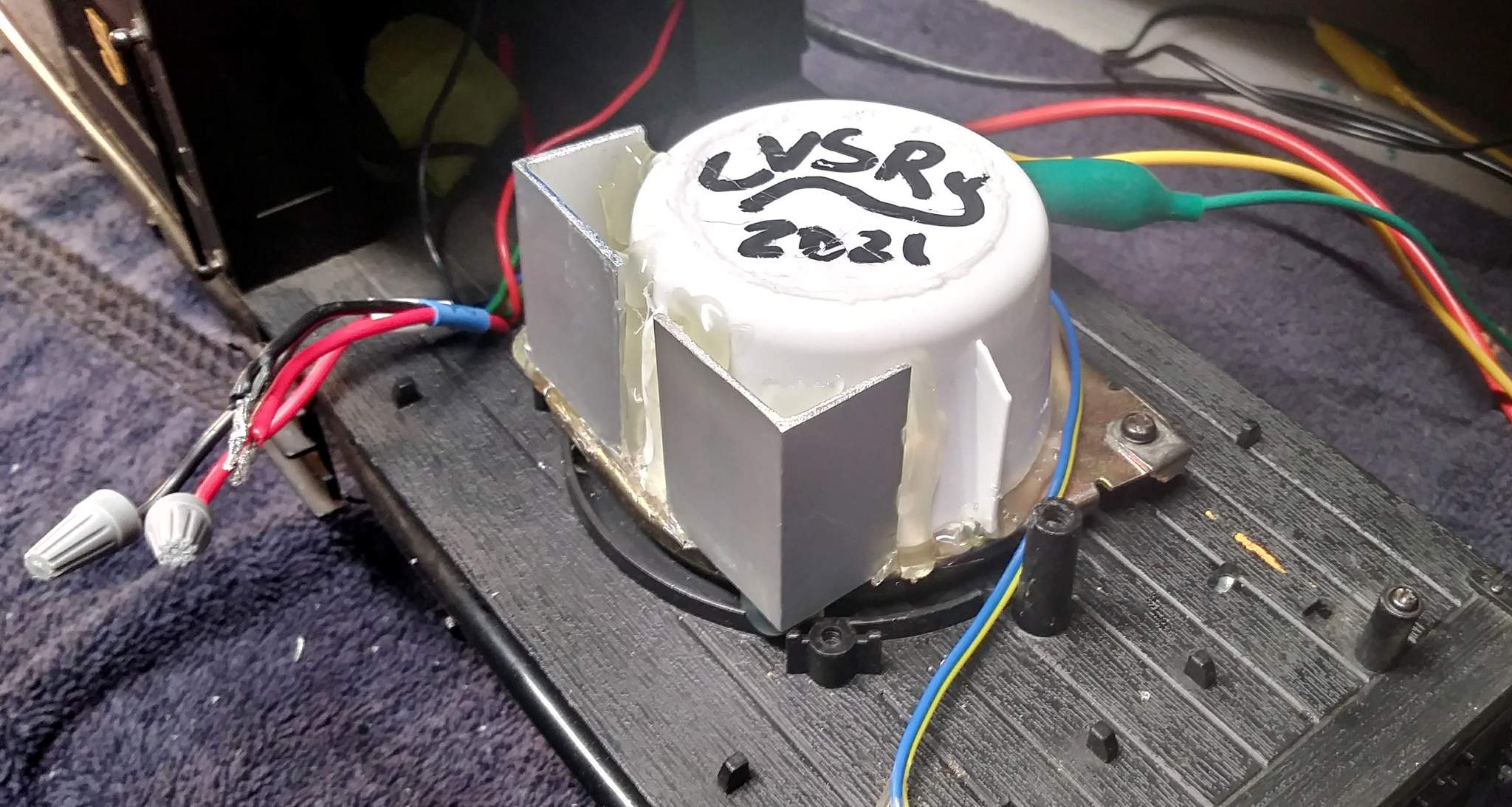

I’ll take pictures as soon as surgery begins. One item to be extracted is a Phoenix Big Sound 97 board with Shay chips. That will be available soon if anyone needs.