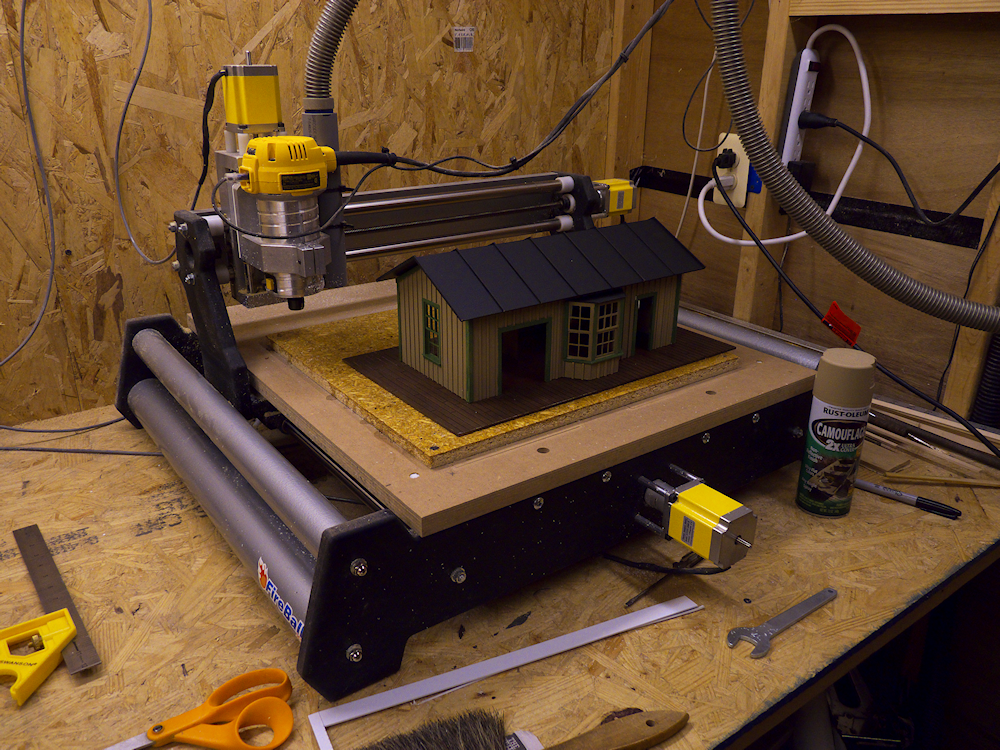

Thought I would post up some of my plastic experiments. I’ve been working with some 1/8 inch styrene sheets. I’m trying to cut out a generic sort of N&W depot (for reference- Winfall Virginia depot from the Virginia Tech Archives at http://spec.lib.vt.edu/imagebase/norfolksouthern/full/ns1130.jpeg). I’ve melted more than a couple of sheets into a mess but I think I’m finally getting the hang of it. I’m using a 3 flute soft media bit from precise bits, MM3I8-0370-017F and running it at 7500 RPM with a 25 inches per min feed rate. For engraving the grooves for the .080 square strips I can do a single pass but to cut all the way through the .125 sheet I have to do three passes .030 deeper each time. If I go deeper or faster I get a melted mess. Nasty and ruins the part.

Here is the raw cut of the end of the depot-

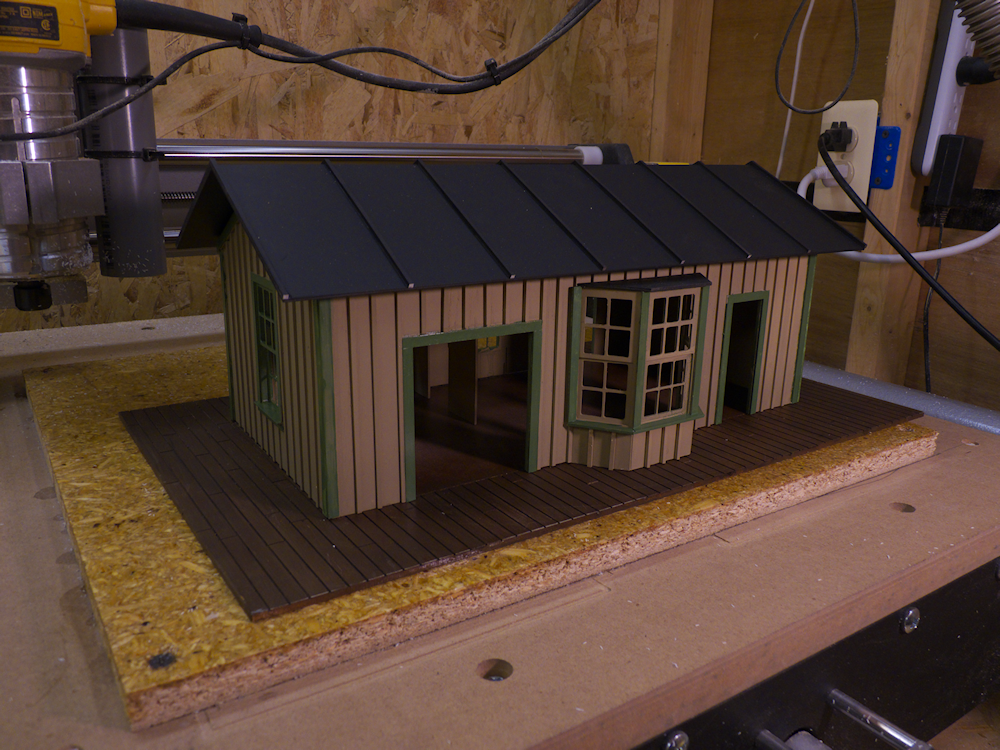

The .080 square strips and window trim roughed in and finished with a shot of brown primer-

Not great but it’s looking pretty decent. Progress!