Now that is one impressive project Detail is awesome. Later RJD

Update: A certain club/lsc member, I won’t mention his name (coughAndycough)  mentioned last weekend that the crew is slacking lol. So with ice and snow moving in and a fire under my can, here is a long awaited update, though a small one.

mentioned last weekend that the crew is slacking lol. So with ice and snow moving in and a fire under my can, here is a long awaited update, though a small one.

Started work on the small vertical steam engines located on the engineers side of the skidder. these are used to operate the larger upper spools of cable used to raise and lower the tower.

Here is a picture of the engines on the HO model

http://i1050.photobucket.com/albums/s414/trainbuffjr1/smallengineforupperspools004_zps176dfd7c.jpg

And here is my version in G scale. They were constructed from wood spools, washers, styrene, Kadee coupler nuts, and metal rod. This one is on the front

http://i1050.photobucket.com/albums/s414/trainbuffjr1/smallengineforupperspools001_zpsb91cc8da.jpg

And the one on the back in front of the boiler

http://i1050.photobucket.com/albums/s414/trainbuffjr1/smallengineforupperspools002_zpsb746be83.jpg

More to come soon…

Aaron Loyet said:

Update: A certain club/lsc member, I won’t mention his name (coughAndycough)

mentioned last weekend that the crew is slacking lol. So with ice and snow moving in and a fire under my can, here is a long awaited update, though a small one.

Started work on the small vertical steam engines located on the engineers side of the skidder. these are used to operate the larger upper spools of cable used to raise and lower the tower.

Here is a picture of the engines on the HO model

And here is my version in G scale. They were constructed from wood spools, washers, styrene, Kadee coupler nuts, and metal rod. This one is on the front

And the one on the back in front of the boiler

More to come soon…

Pics are a bit large, but there is progress. Nice work Aaron

Thanks Dave! Forgot to resize them, probably will post another update tomorrow or Saturday, so I will try to remember this time

Aaron Loyet said:

Thanks Dave! Forgot to resize them, probably will post another update tomorrow or Saturday, so I will try to remember this time

With the new photo editor, you can simply grab the corner of the photo and resize it. It works great.

Aaron Loyet said:

Thanks Dave! Forgot to resize them, probably will post another update tomorrow or Saturday, so I will try to remember this time

If he doesn’t, I think someone will mention it to him on Saturday…

Aaron

Looks good…with the new format instead of direct linking on photobucket just use the img tags now and you can skip the insert image as the IMG tags will open right up where direct link no longer does. You can also resize right on PB as well.

Wow! You said you were working on it. Nice

So after almost 2 years of being dormant, time to resurrect this thread to show where I am thinking on this project, and to get some input.

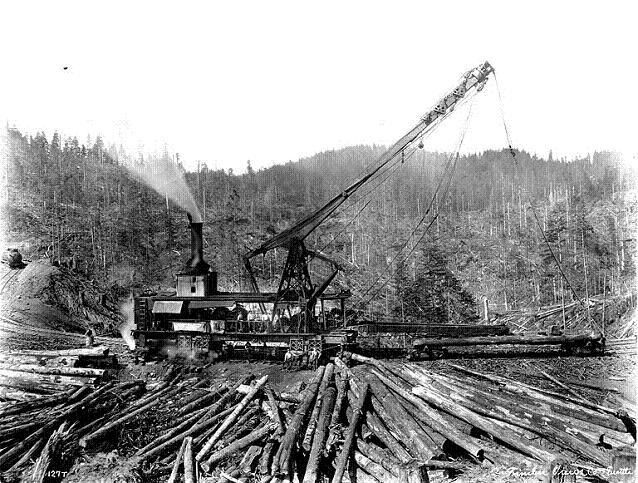

Though I really like the look of the Willamette original design, the boom design has been nothing but a headache, building all of it from styrene would be costly, and make for a weak structure, and going brass would put me in the poor house lol so I looked to the rebuilt version. Less than 10 years after being built there was an accident involving a large pulley block falling from the mid tower section about 50’ up, down through the tower and onto the front loader, killing the operator. The rig was redesigned and built just like the Lidgerwood skidder (some say Lidgerwood did the rebuild) It looked just like the Lidgerwood below when finished

This would be a much sturdier tower, and much easier to build, but would require more steel to support the structure on the front. This was going to be the new design using what I already have, and leave it at that, but other problems arise.

The purpose of the build was that it could then be moved and set up for operating sessions, however with the overall weight of the rig so far, along with the weight hanging out over the track, and sitting on top of moving trucks that are not mounted, made for a very unstable design, and I high center of gravity, making it very wobbly moving down perfectly level track, so in a garden with grades, this would be impossible. So I started studying the rig at Cass

With this design, it would cut back to two trucks, permanently mounted, allowing for little sway action, also allowing one ‘spine’ running down the car, putting the center of gravity back in the middle instead of out the sides, and lowering the center of gravity close to an inch. Also, with this tower design, it would fold back onto the rig, allowing it to be more centered, and moveable with a couple flats for idlers, and keeping the front loader design of the Lidgerwood and Willamette models, as opposed to the front lowering design of the Lidgerwood, adding a lot of weight out the front for moving, and many more flats to move it.

So current idea running through my mind, build a new frame, similar to that of a really long skeleton log car, using either a hard wood, or some steel tubing, then build out from that. then removing everthing from the deck up on the original design, and transferring it over to the new frame, keeping the more open design I had originally and the overall size, but a much more mover friendly design, and lighter as well.

Still need to pull out a napkin for the “official blueprints” but this is the thoughts on hand at the moment. Any comments or suggestions on design would be appreciated (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

I hate to see all the time you have spent on it so far, being wasted, but it did give you some hands on experience with it’s construction… It’s not fun, building something, then watching it come apart…

The Cass design is a bit simpler, and workable as a ““movable”” object…

However, the project is all yours, and you are the one to say what/how it will be done…

Either way, knowing how you construct/modify things, it will always be a great model…

Best wished, Aaron…

It will that. But fortunately probably 90% from the deck up can be recycled into the new design, just jacking it up and sliding a new frame under it. Though all that time punching and glueing rivets will be shot to heck lol

Well, I hope you had fun counting them, as you punched and glued them. (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

More! More!

Andy Clarke said:

It’s not fun, building something, then watching it come apart…

Yes it is I do it all the time!

With the Lidgerwood boom design change you are sticking with a prototype design that was field engineered after shop design failure  and put into use as a Willamette tower skidder. I haven’t really studied the Cass machine but my thoughts are that it is a totally different machine than a Willamette Tower skidder. Made to handle different timber under different conditions with a different rigging system??? My thinking is that if you change to the Cass machine design you have redirected your build effort, am I getting that right? No matter what you decide I sure will enjoy seeing this project move forward.

and put into use as a Willamette tower skidder. I haven’t really studied the Cass machine but my thoughts are that it is a totally different machine than a Willamette Tower skidder. Made to handle different timber under different conditions with a different rigging system??? My thinking is that if you change to the Cass machine design you have redirected your build effort, am I getting that right? No matter what you decide I sure will enjoy seeing this project move forward.

Rick

Work his mind Rick he needs it!!!

(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Give that man a cigar!! It is a different design Rick, it has lidgerwood components I think, but it is shop built. Has a close look in some ways, but the frame is totally different, and boom design is a bit different. The boom is like a square beam, which turns into a large pipe at the top, as opposed to the lidgerwood boom. My new design will probably contain parts of each design, the williamette, the lidgerwood, and the shop built version

David Russell said:

Andy Clarke said:

It’s not fun, building something, then watching it come apart…

Yes it is I do it all the time!

. Lol I know the feeling, I’m surprised I haven’t worn out projects tearing them apart time and time again

David Russell said:

Work his mind Rick he needs it!!!

(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

. Yep , it needs work alright hahaha

Wow, too bad to have come so far and then have to make major changes, but hopefully you can save most of your existing work on it. Very impressive project.