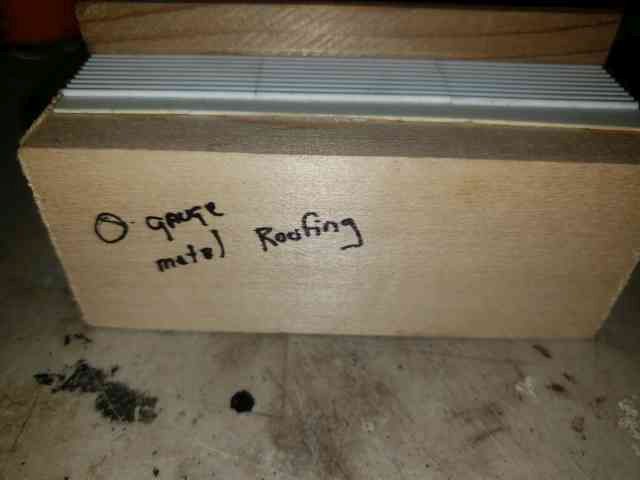

A friend made O scale corrugated iron using smoothed out aluminum foil baking/BBQ trays.

He made a bender and the "iron"by;

- gluing Bamboo skewers (you could use dowel) onto 2 wooden frames

- then sandwiched the foil between

- then just pushed down to create the corrugations to make the “iron”.

This is similar to what I do with my paper crimper for my G scale iron.

Trying to describe the frames imagine a 6"x 3" rectangular wooden frame which has grooves cut into it that accept the skewers, the skewers are glued into the grooves bit leaving them proud.

To make the grooves clamp the 2 frames together and drill holes that same diameter as the skewers and you will end up with semi circular grooves that will leave the skewers proud by the radius of the skewer.

Hopefully I have describe this so that you may understand, its simple, cheap and an easy way to make “corrugated iron”.

I might even use this method for my indoor HO layout just reducing the size of the skewers by half (HO= Half O)

Sadly my friend passed away from cancer, but I am using all his HO track work for my indoor layout with his widow’s blessing.