OK,

My head hurts, but from the electronics (I barely passed electrical engineering back in the day). The first thing I really had to do was figure out how we planned to use this - however it turns out - to see if the suggested motors would work.

After reviewing Johan’s websites, I focused in the https://www.pololu.com, as it was the most user friendly.

My kids have a new LGB 2075 (Christened Christmas Thomas) powered by 3x “C” batteries wired in series, which is 4.5V. It happily pulls 3-4 “minis” for about 30 minutes, then I need to start pulling cars. By ~2 hours it won’t pull anything around R1 curves. Over the course of a year, it probably gets ~1 hour on the rails per month, time being limited by the cost of C batteries and the fact the IR controller is not LGB worthy…

Using John’s suggested motor, the TAMIYA 70103, and cross-referencing that to the Polulu website’s performance data (https://www.pololu.com/docs/0J11/5), I should get about 16 hours of life at that voltage. I can live with that, but it means designing motor replacement into this project. To boot, with information forwarded courtesy of Bill from another forum, a gentlemen there posted that he used two motors, one fore, one aft, and got about the pulling power I am after, albeit with a 9V battery.

Using all of the above, to include motor specs, I am assuming a 4.8V, 2200mAH battery pack is the right choice. I will take on the cost of the charger as an investment in the hobby, as I can see it having other applications down the road. Battery power will also dictate the shell come up easily from the frame.

On/Off switches were incidental costs. I did not see anything that screamed “reverse / speed control.” I would like to be able to put this thing in reverse. Speed control is nice, but not required.

So, as I see it, I am in for 1x (or 2x ?) 4.8 V, 2200 mAh battery cells connecting to two motors wired in parallel with an on / off / reverse switch in there somewhere and a charger. What am I missing in my least favorite subject matter?

As for what this will power, there is physical space to make this look like a gear driven loco. The cylinders slide in and out of the lower part of the chassis, so they can move up. It would require more cutting and filling, and it might force me to dicker with what looks like the downcomer to make it look right. Regardless of where the cylinders go, the fact remains I have to figure out a way to drive the cog that will look like it is the thing powering the drive wheels via a chain linkage. From John’s diagram, this looks like it could be a fairly simple contraption, and the R/C airplane store may have something that would normally be used in that application.

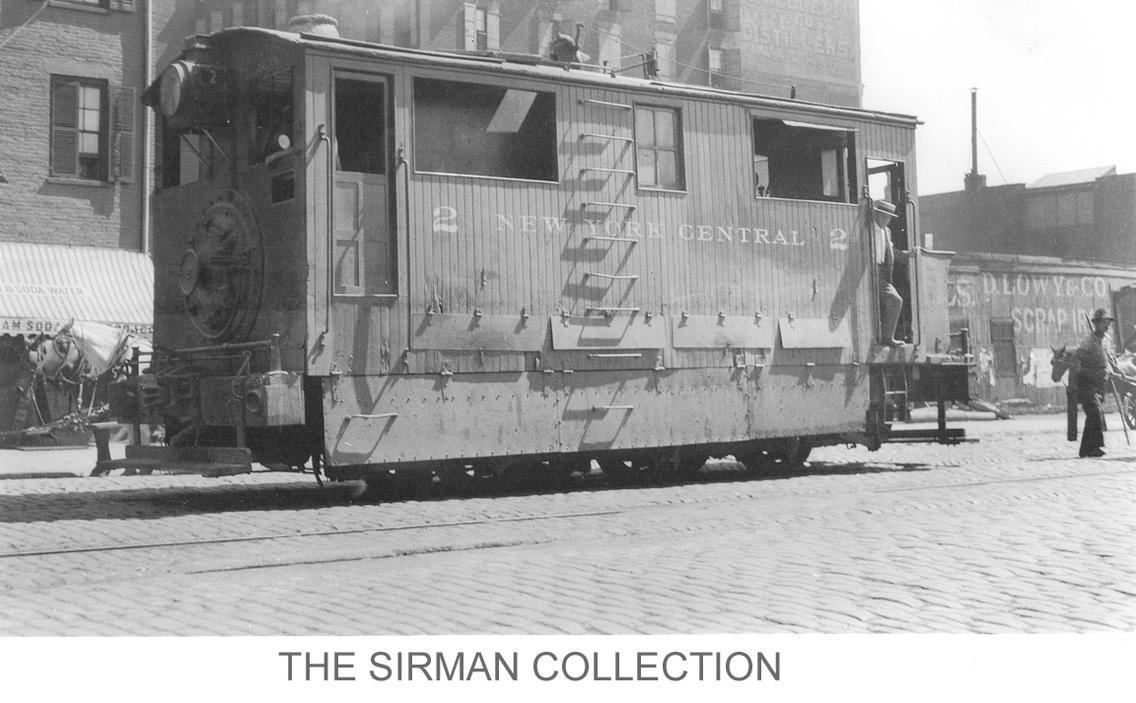

If we go with a tram / steam dummy option, I tend to agree with Rooster the full tram like the NYC ones is better for a “from scratch” or radically different starting point. My skills are not there yet, and, as mentioned, I’d like to see this old thing get rolling again.

Now my head is well and truly blow. If the powerplant looks like a 75% solution, I’ll double check with the supplier and get those parts flowing by the end of this week.

Have a great week, and thanks for sticking with me!

Eric