Answer to my own question, I guess it can.

Thanks for posting that Wayne. I’ve seen a number of photos of exploded boilers, but not an explanation of their cause and horrible effect on the crew.

Not sure when the practice started, but the firebox on our locomotive on the Dry Gulch RR had a safety plug on the crown sheet (inner roof) of the firebox. It was basically a 1/2 inch ID tube filled with solder. As long as water was above the crown sheet, the solder would not melt. One day we had trouble seeing water in the sight glass, and the boss told me to remove the fire. As I was taking out the last shovel of hot coals, the safety plug melted. YIKES!! 150psi trying to get through a 1/2inch hole sounded like a SAC squadron had scrambled right beside me! I jumped clean over my shovel and didn’t even know it! The device did what it was designed for. If there had been any fire left, that steam would have put it out!

Regards, David Meashey

Only if you want to model it. If you are asking if one of our live steam engines would do that, the answer is no.

Some years ago, a group in Australia which included Paul Rishon, did some scientific tests using existing copper boilers. They pumped them up to around 1,000 psi to see what it would take to burst them. As I recall, they didn’t burst - the seams for the end caps gave way slowly.

General opinion is that there isn’t enough inherent energy in the steam in our locos to actually cause an explosion, even if the boiler ruptured.

1,000 psi is great if possible but you forgot the HEAT part ?

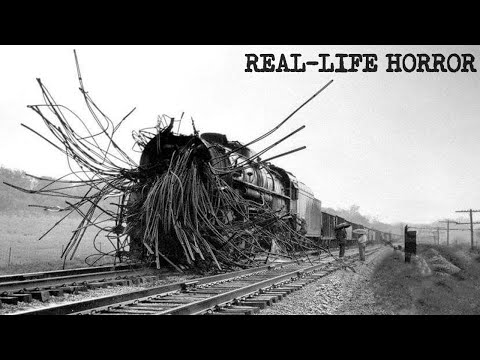

Seems to me since everything blew out the front that they crew might have been able to escape a lot of the steam, but without seeing other pictures you just don’t know what blew where.

Yes, I’m thinking the same thing, need the heat. I am still going to believe if miss handled/ or miss operated my new to me live steam mogul can hurt me.

Video said all three crew suffered from steam burns and later died. Really tough to get out of the way of an explosive reaction.

I wasn’t there, but I don’t think they did. The article is online if you want to read it.

Without the steam, as soon as the boiler fails pressure is lost. With a boiler that is not completely full of water has a lot of room for pressurized steam. When the boiler fails with steam, the volume of steam still has to exit. This action, in my mind is what tears apart the boiler.

In reference to the water heater, all of mine have had a safety valve. I would think the safety valve would dump excess pressure should it start to build up. The water heater in the video did not show a safety valve.

Just sayin’, David Meashey

Testing quotes which makes sense to me. Have always instructed my son : " If you want to learn something just ask an old guy"

That is why our live steamers have safety valves. The one I am working on has 2 of them! Many leak at 20 psi, and I have never heard of one being set for more than 60 psi. Note that the tests, steam or not, were up in the 250 - 1,000 psi range.

Nor have I ever heard of a model boiler like ours actually failing. Lots of leaks reported due to bad solder joints in the pipework, but the actual boilers never seem to have a problem.

Pete;

There may have been a misunderstanding concerning my post that you quoted. I was actually referring to the exploding water heater video (above), and stating all the water heaters I have owned had a safety valve (probably set below 40psi). The water heater in the video probably had the safety valve port closed.

Our little live steamers do have adequate safety valves and are very well made.

Regards, David Meashey

I am sure the purposely removed the safety valve to do that experiment.

It looks like that loco threw up!