The crew of the afternoon train foolishly ignored the slow order while passing through the yard lead switches approaching Honey Grove today. HEP car 152 picked the Kistler Yard switch derailing itself and the following car. Normally this would have been just an inconvenience, however a bolster failure caused the rear truck to be ripped from its mounting putting the HEP car out of service until it can be repaired. The staff photographer rushed to the scene and snapped these pictures just after the wreck and during clean-up. The scene in front of the Honey Grove station…

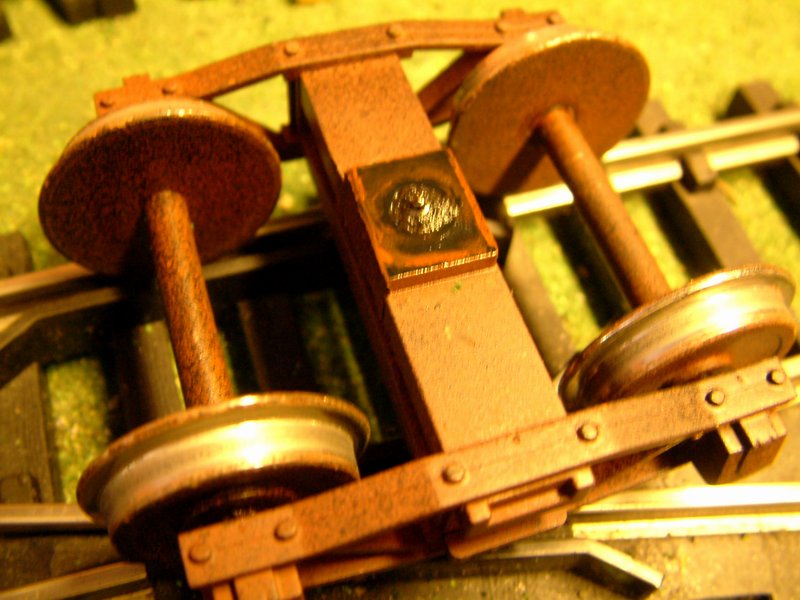

The rear truck of HEP car 152 was ripped from the bolster as it was pulled along the Kistler yard lead…

Passengers waiting on the platform at Honey Grove were lucky to escape injury, although it does appear that one freight worker fell off the platform while backing away from the wreck…

Car 153 also derailed, but was quickly re-railed with no damage…

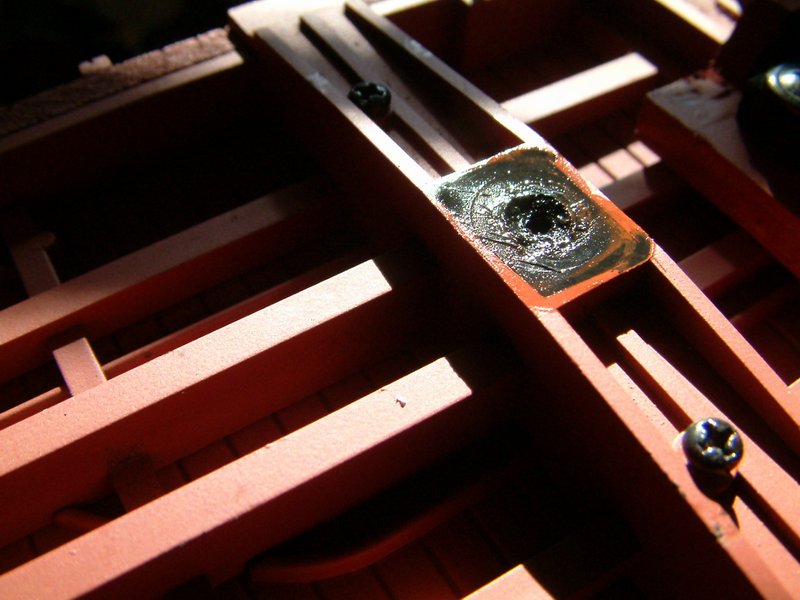

After clean-up was complete, the source of the failure was discovered…

A repair made when the car was refurbished failed under the stress of the derailment…

Car 152 was immediately dollied to the shops where the frame was separated from the body. The Over Engineering department has been called in to design a replacement for the broken bolster pin. Placing car 152 out of service effectively shuts down diesel operations on the C.V.S.Ry. The railroad does have two serviceable steam locomotives that will be called in to keep things moving.