The last step in preparing J&B #4 for road trials was a bit of paint. Most of the boiler and tender just needed cleaning and touch-up, but the cab roof was in need of refreshing. I masked with delicate surface tape and a plastic bag…

Then shot two coats of Rustoleum Rusty Metal Primer…

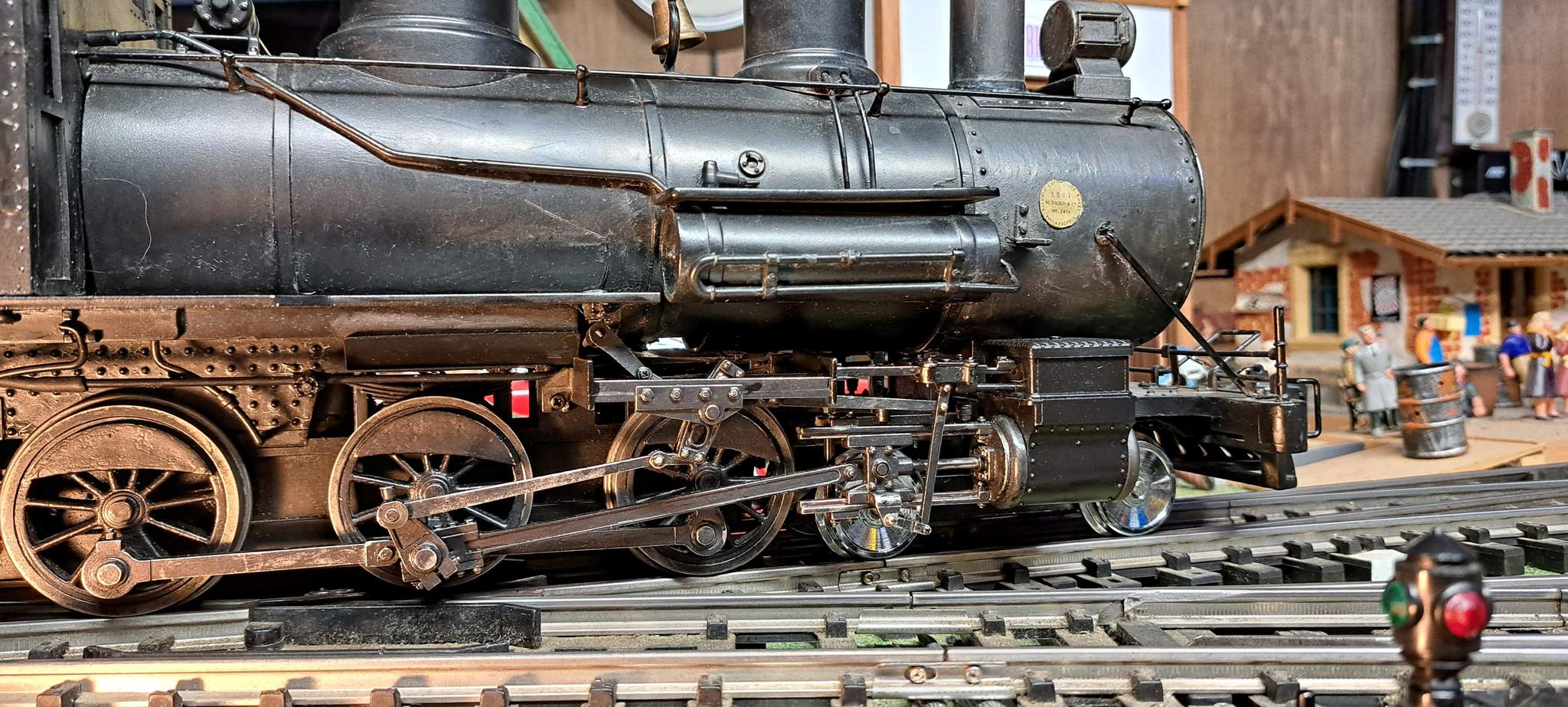

When that was dry, #4 returned to the rails, was mated with her tender and proceeded to run road trials on the outdoor. First up; a passenger consist with a caboose…

Unfortunately, the 4% was just too much and she started to slip even before the curve. M-11 was called out to assist up the hill…

#4 was able to handle the braking duty down grade without assistance…

Then it was time for a very special run. An all Jackson & Burke passenger consist…

The caboose arrived first after a long circular route from Burke, VA to Connecticut via Ottawa Canada and Northern New England…

The passenger consist first went to Ken Brunt and later to me via his estate sale. Seen here approaching Wall Station up-grade. This consist is significantly lighter and #4 handled it with ease…

This scene would not be possible without the modeling talents of Bruce Chandler and Ken Brunt…

I want to express my thanks to Bruce for this engine. It has wonderful details. fantastic character and runs quite well…