Would he be on the chat line perhaps? Where is  when you need a rude comment.

when you need a rude comment.

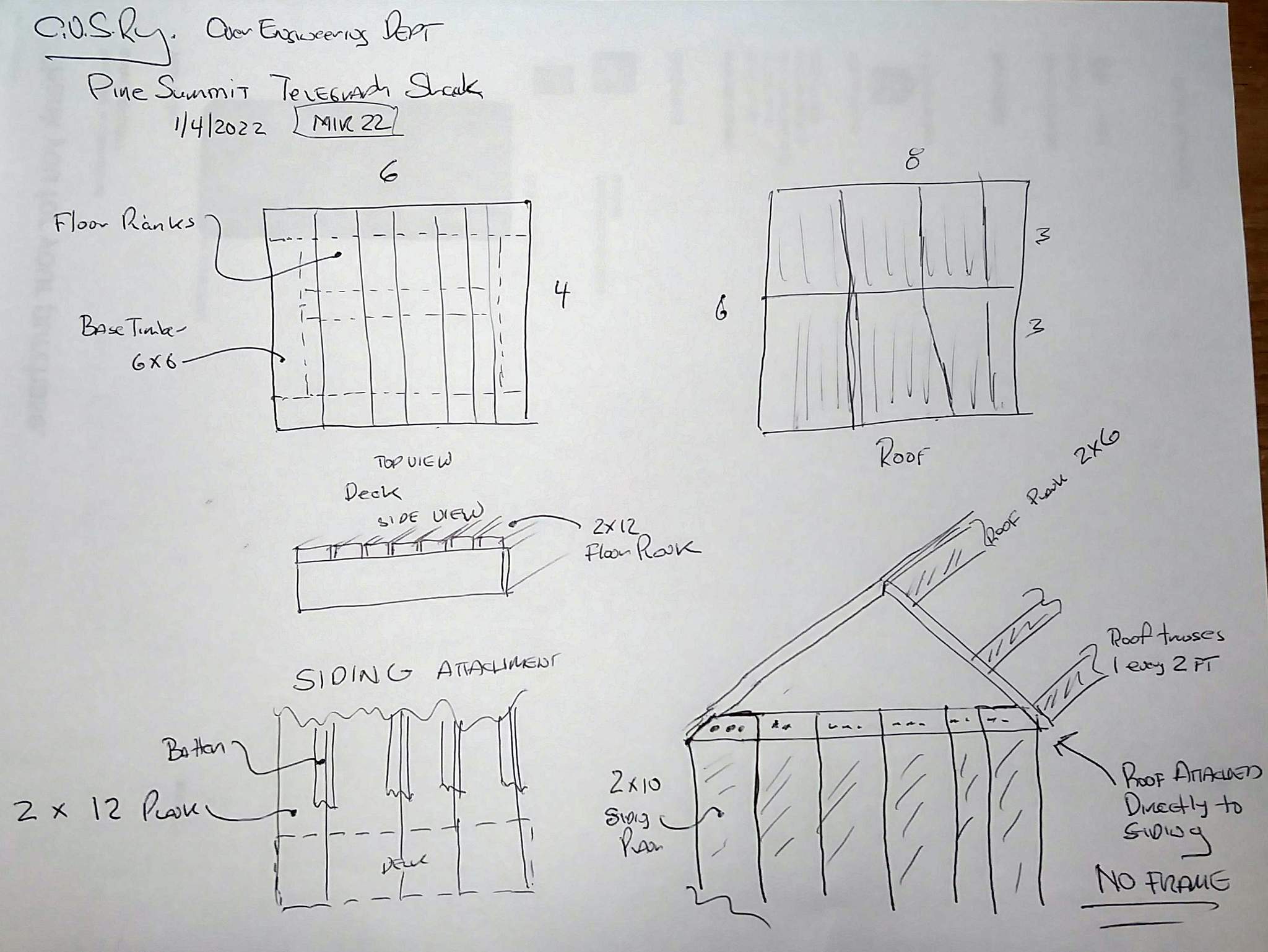

So, I decided since this is a relatively simple structure with very basic elements that I would forgo drawing the plan on the computer and just do an old school sketch the way I plan builds at work. So the new name of my entry is the Pine Summit Telegraph Shack…

I still need to work out a few more details on the roof trusses, but I’m guessing they were pretty light and probably less than 6 of them.

I had thought of not allowing the door to open and just build the exterior on a block of cedar, but the fun is in the structure, so the door will open, even if just enough to peek at the floor and let some light leak out. I’m not planning any interior detail like the stove or desk & chair. I have a great picture of a recently departed friend acting as a station master in the tiny Chester, CT station that might work inside.

I think it came with a few other caveats too, but I insisted you take my money.

I think it came with a few other caveats too, but I insisted you take my money.