The railroad has experienced some growth in freight traffic, and has caught the eyes of RR inspectors, the upper Babs River bridge has failed inspections and has to be replaced within the next 90 days, or stiff fines will be levied. So the main office has issued a purchase order and a nearby multi purpose Shop has been awarded the contract to build at least 1 bridge, with an estimated scale length of 80’ and some new base footings will also need to be constructed and set. But first the great Christmas party of 2005, and founder Babs

After the Christmas party a survey was taken and careful guesses on length and WAG’s on height from precision photograph of the location

back at the shop, a template was located from a previous build, some modifications were made to the sizes and work was commenced.

Suitable material was located in a storage area nearby. I had replaced all the sun screens last spring and so plenty of material was available

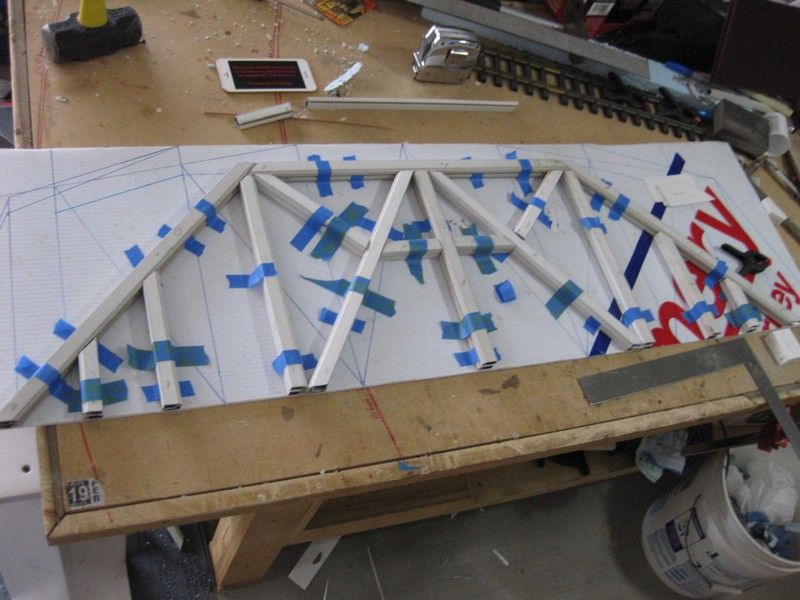

Construction began by almost clearing enough room to do some construction and cutting with a hacksaw and a small miter box to assist on some of the angles. Using a method shown here on LSC I cut and laid out both sides of the project using my miles of tape the hold things together plan.

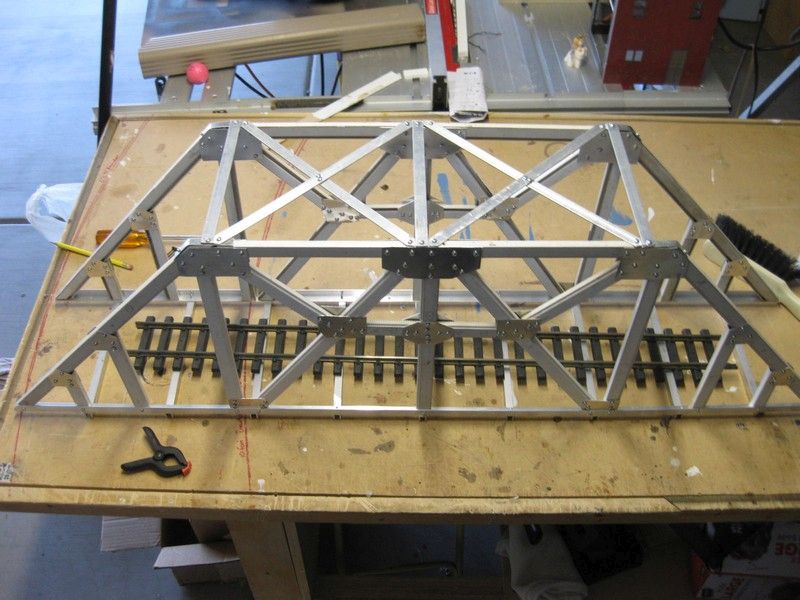

both sides all cut

you can see the cardboard templates for the gussets are sitting on their various spots, and as one nice man who will not be named (Bobcope) said " gussets, good they hide oops. Obviously he has looked at other builds from this shop!

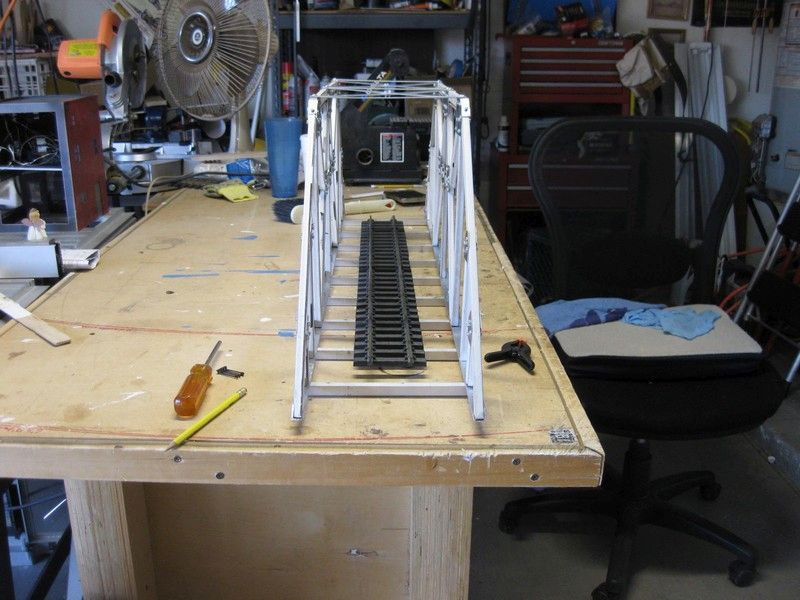

Next was to pick the base material for the roadbed, again, calling up previous work from LSC and a fine gentleman here, Diesel Dude, a plastic milk crate was cut up to add to the structure. Since this is a single track bridge, , this one will be wide with plenty of clearance for whatever rolls through

And just for informational purposes, this is the material used, Aluminum screen frame , it is sold at the 2 Big Box Home centers in I believe 6 foot lengths, this bridge will be getting painted, the last one was left as bare aluminum. More as it comes together.