I’m moving this here so as to not take over Rick Marty’s Spring Switch thread in the general forums. For continuity here I’ll re-post a few photos from that thread.

Early Spring 2020 clean up discovered my Aristo stainless #6 switches need some cleaning and work on the throws. I bought a bunch of Bachmann throws from RLD at ECLSTS 2019 with a plan to replace all the Aristo throws outdoors with the Bachmann throw as I find they have a much more positive closure. The problem with that thought is that three of my 5 #6’s outdoors are set up as spring switches so I can negotiate a wye without throwing any switches. Unlike the Aristo, the Bachmann throw has no spring option. So; I thought of trying to duplicate this ride-on scale spring switch…

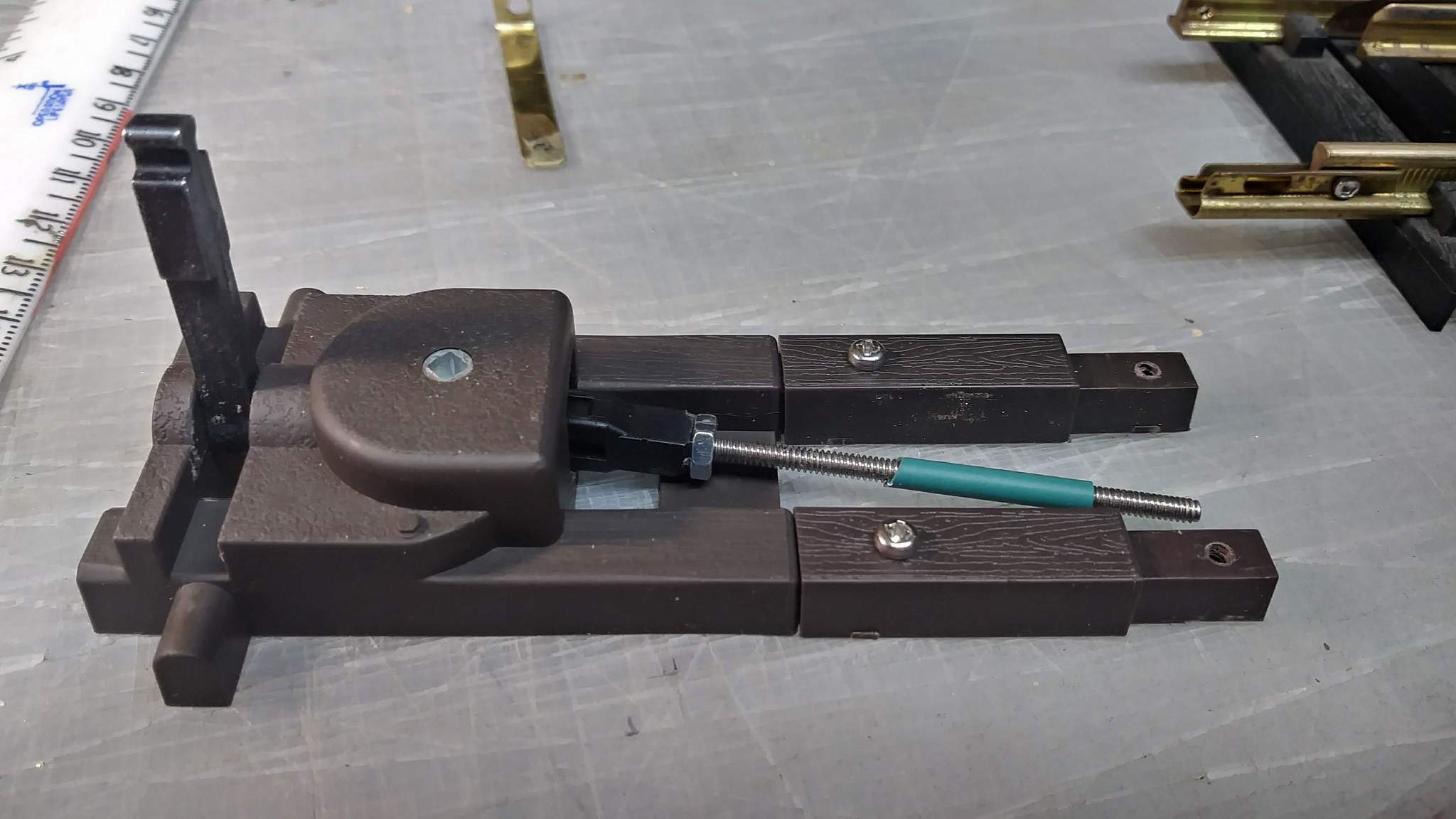

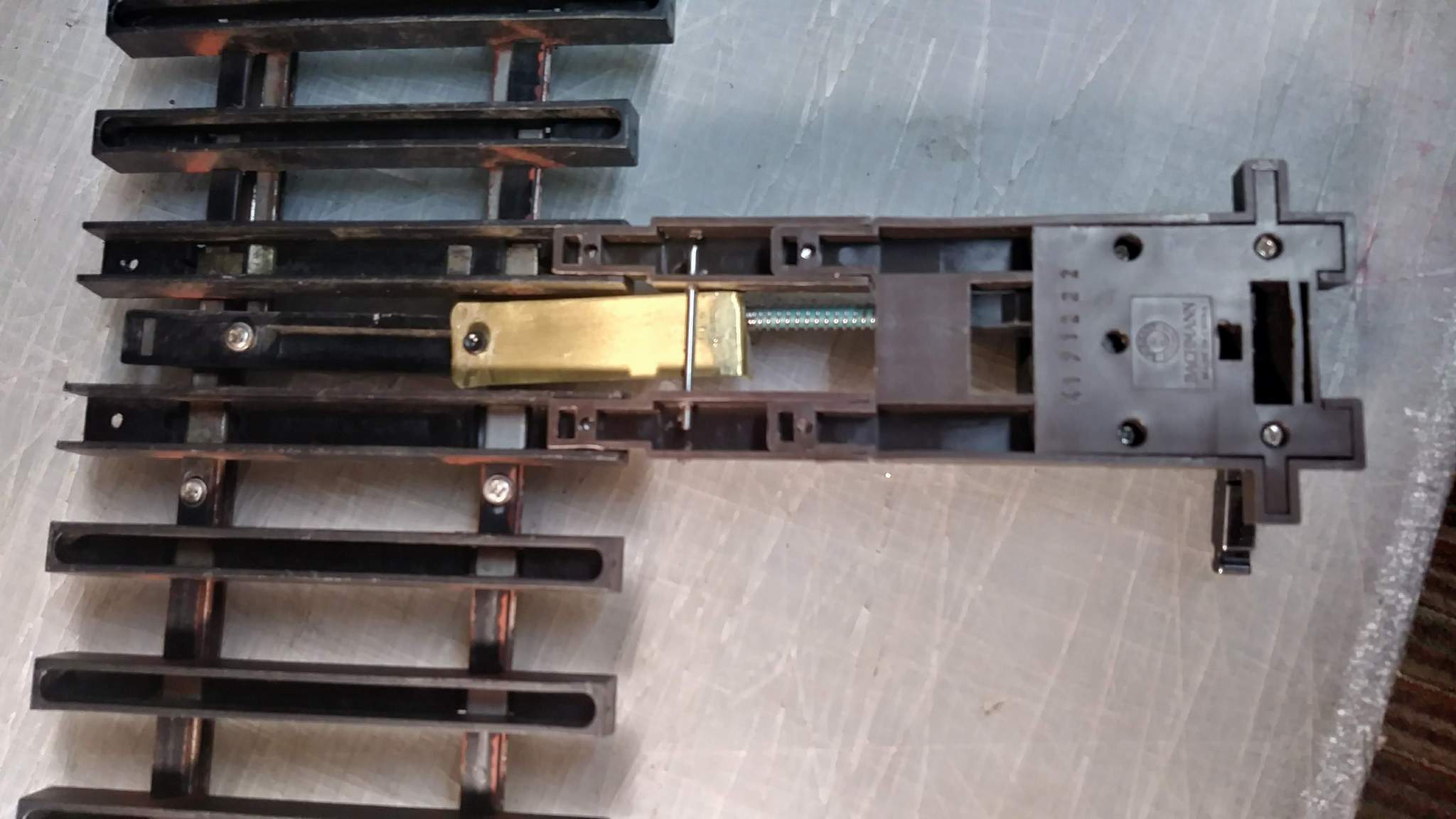

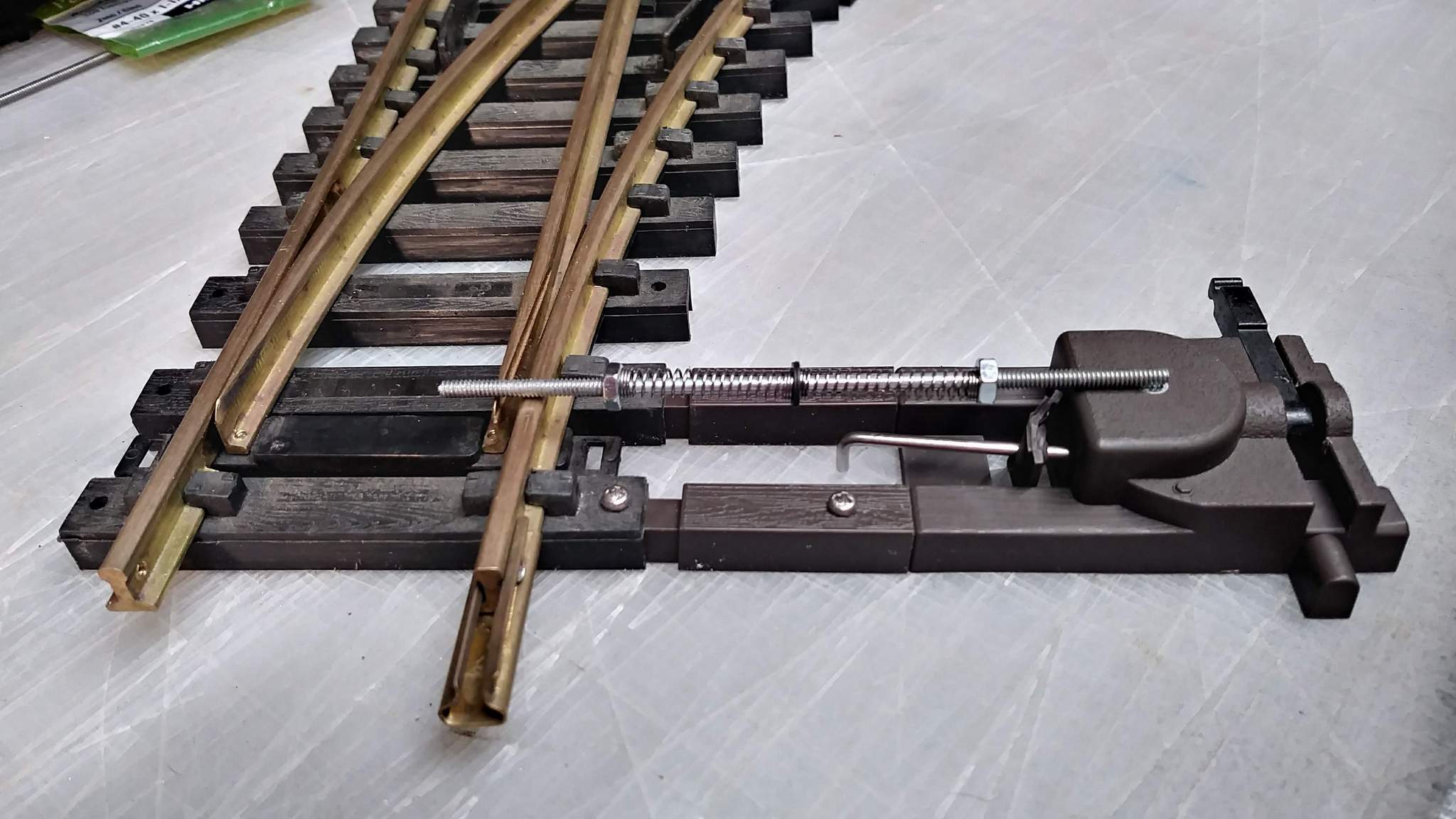

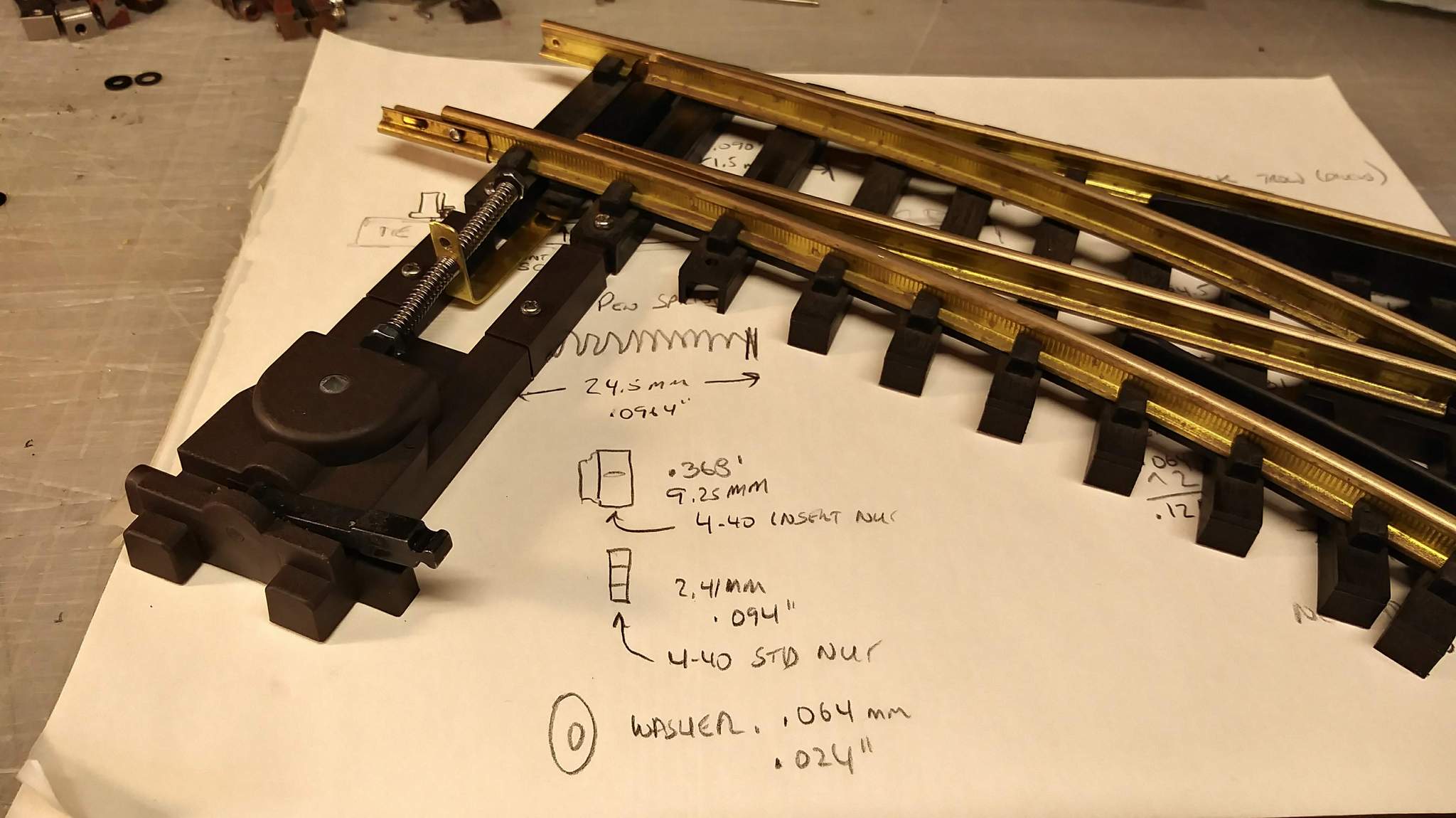

I thought I might be able to adapt a Bachmann throw to stand-in for that red handled throw. My first step in the experiment was to set up some pen springs on a threaded rod to calculate cut sizes and help me visualize how it could work. I’m using an old Aristo R1 as a test platform since it is much easier to handle than a #6…

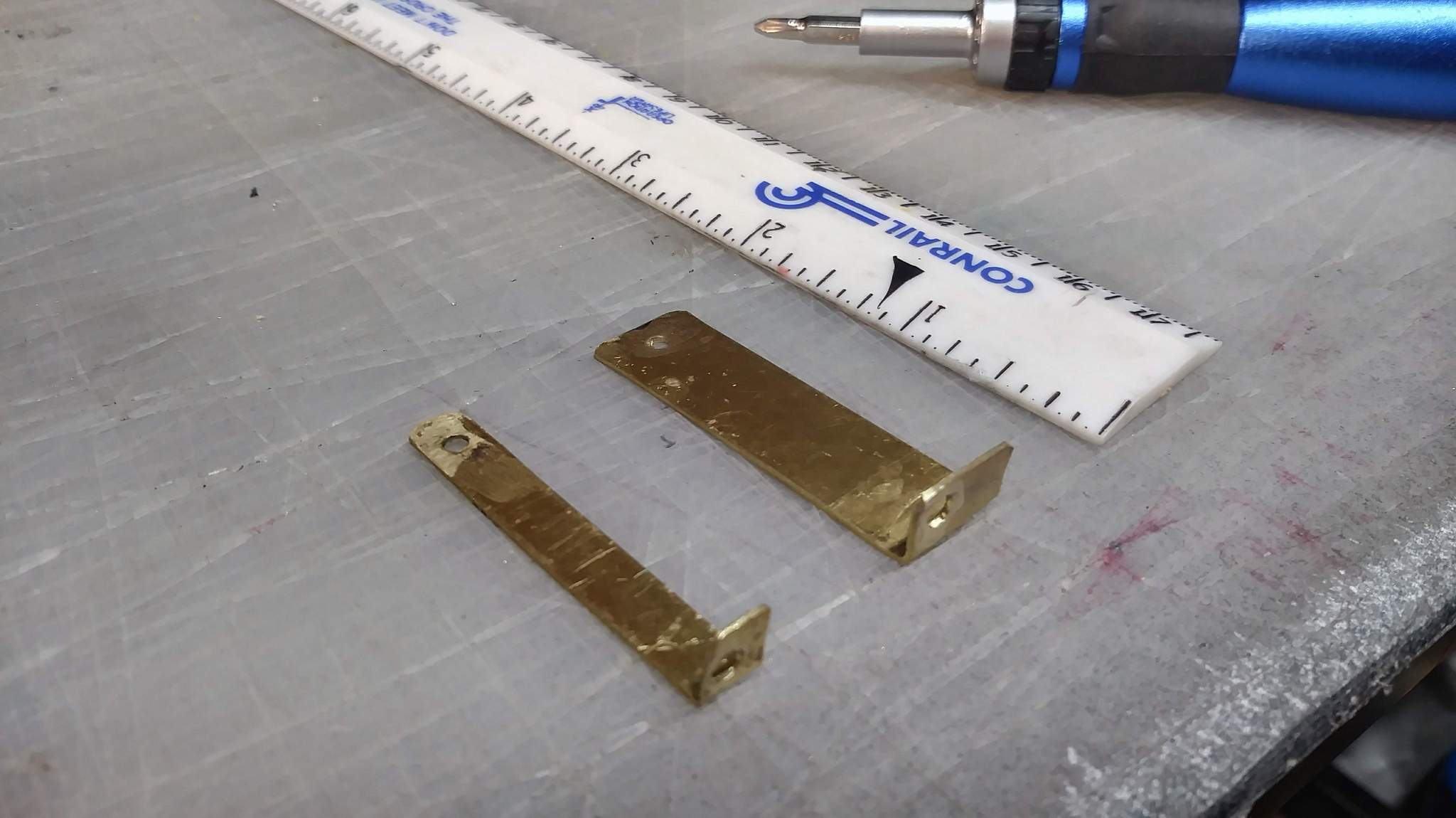

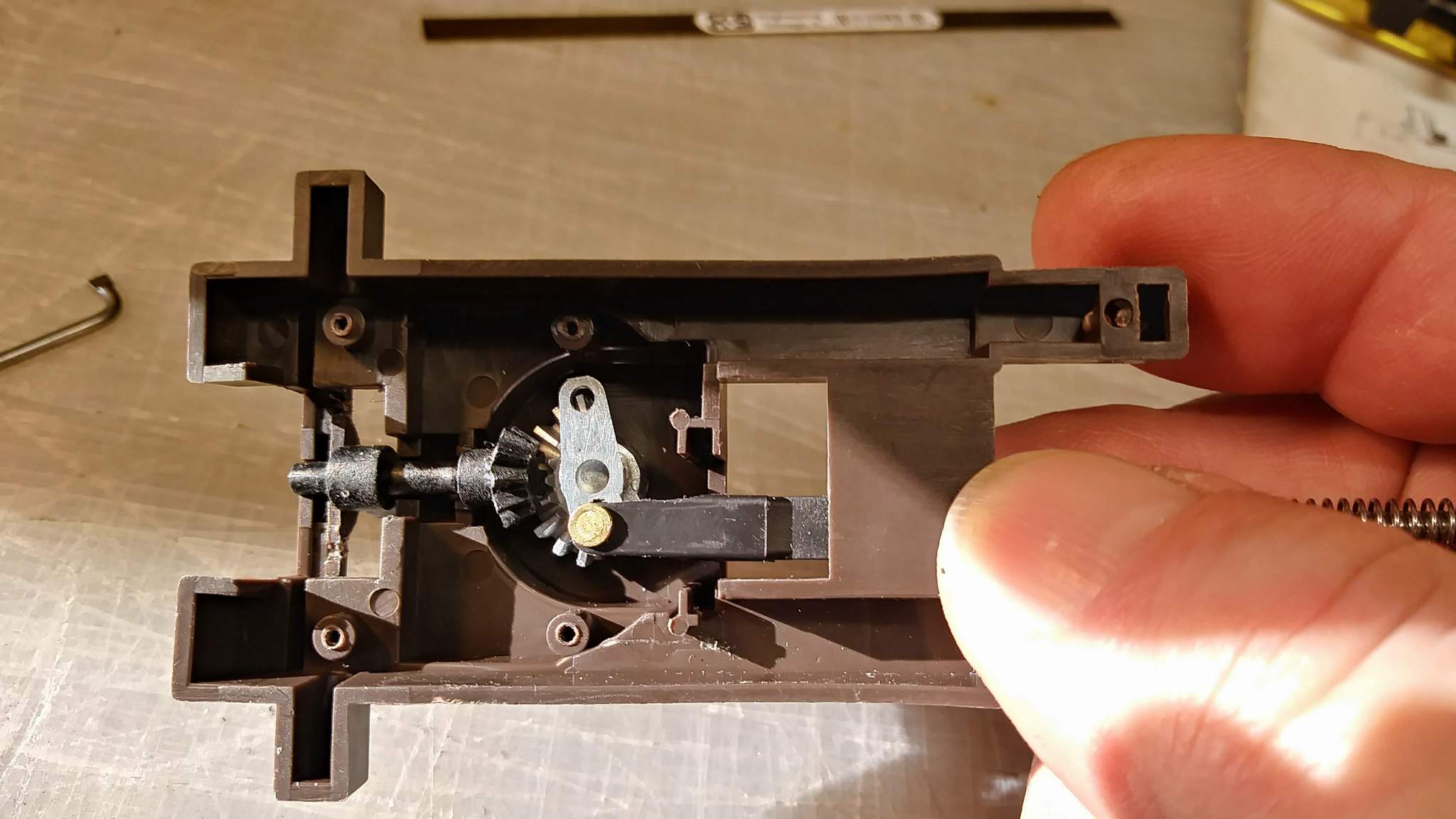

To connect the rod to the inner workings of the Bachmann throw; I purchased some Dubro Kwik-Links at the LHS, who was having a going out of business sale !  I really wanted the much smaller Sullivan Gold-N-Clevis, but he didn’t have them. I found them on-line, but shipping lead time is 10 days and I’m impatient. To get the much larger Dubro to work, I needed to trim it down a lot so it didn’t bind as the throw gear rotates…

I really wanted the much smaller Sullivan Gold-N-Clevis, but he didn’t have them. I found them on-line, but shipping lead time is 10 days and I’m impatient. To get the much larger Dubro to work, I needed to trim it down a lot so it didn’t bind as the throw gear rotates…

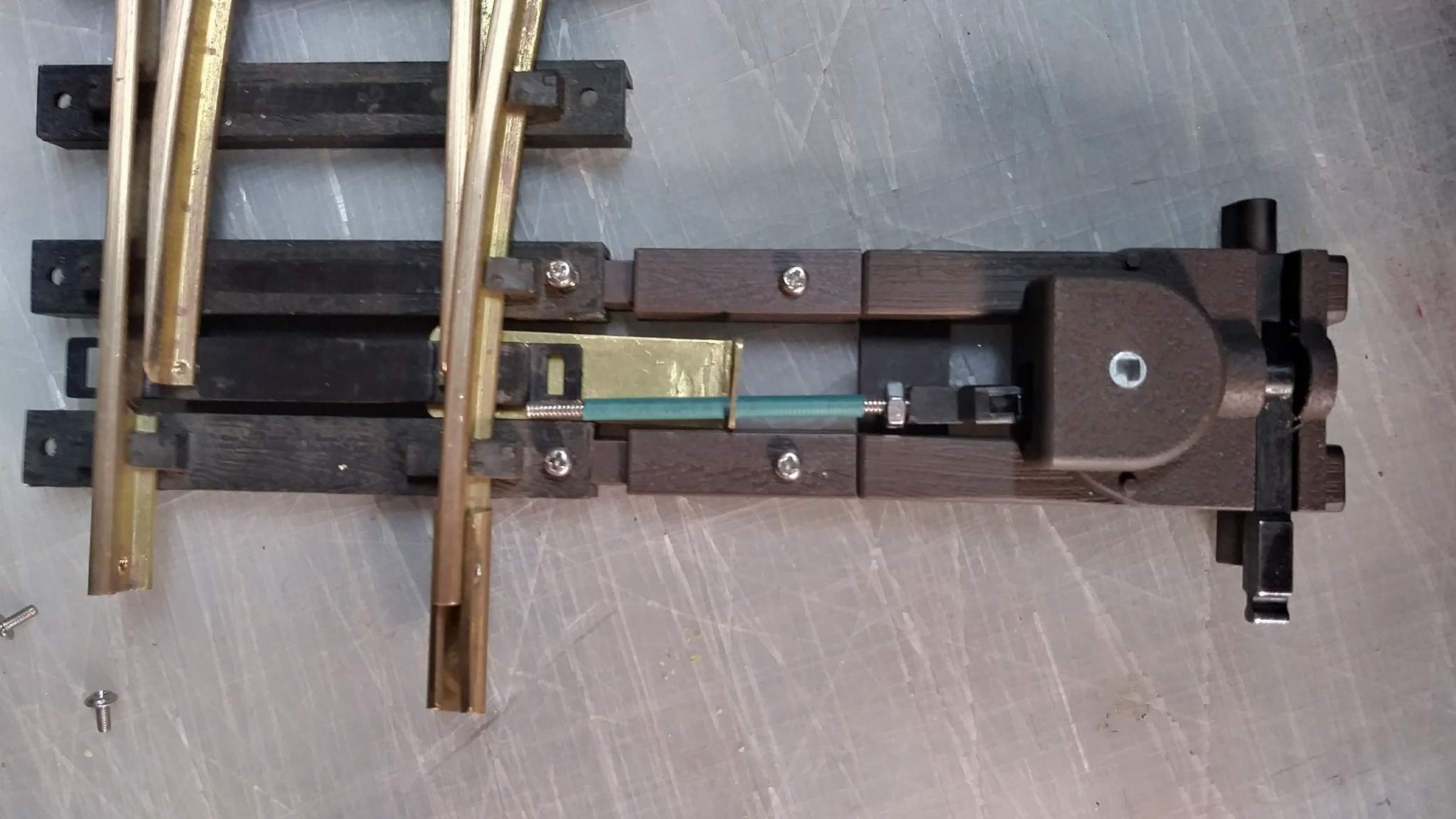

I was concerned that it would not fit inside the machine, but is does…

And the cover closes just fine. It rotates counter clockwise from this view with no binding. I need to trim the clevis just a bit more as it binds when rotating clockwise. I didn’t take a picture of the brass extension of the throw bar I fabricated from brass flat bar stock. So on to assembly of Version 0.01…

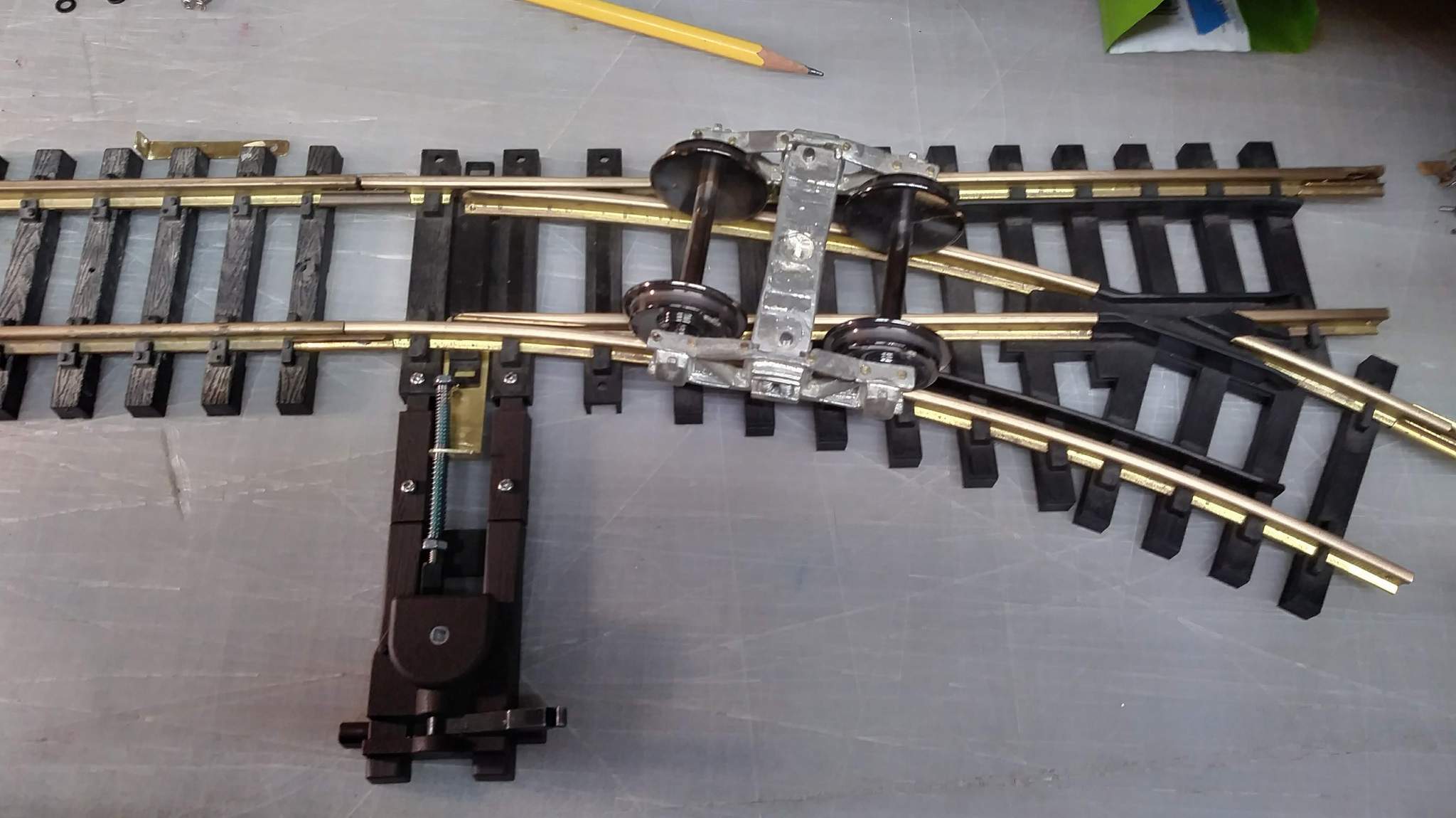

There are plenty of reasons why this version was a fail. The brass extension bar is too long, and the hole drilled too high. When the threaded rod tries to move through the clearance hole in the brass, the threads bind due to the less than perfect line. I took some better measurements and took stuff apart. Version 0.02 features a shorter extension with a shorter rise and a larger hole for the rod to allow for some slop…

BTW, that’s one of Devon’s cast metal trucks. It’s quite heavy, but won’t track cleanly without some extra weight. I’m hoping some of that is due to the sharp R1 points.

One of the problems is that the Bachmann throw is that it moves through an arc as it throws. This system would work much better if the rod stayed at a clean right angle to the rail. This version works, but there is some interference with the Aristo throw bar. You can see it in the photo above. Here it is thrown the other way…

It still needs lots of work. I’m thinking of moving the machine to be parallel with the track, then use a bell crank. This might give me the straight line action I’m looking for.

I’m open to suggestions if anyone has a brilliant idea on how to improve this. It is still a work in progress.