Chuck Inlow had asked me a few months ago to get photos posted of our 1/8th scale trains. I told him I would as soon as I built a railroad on which to photograph them.

Well a few days ago, I started building the track for this “little” layout around our house.

I had some rail leftover from a 7-1/2 inch gauge railroad for my kids from thirty years ago. But the problem was the wood ties. I found the solution to that problem from a company called Northwest Foundry and Railroad Supply in Washington state.

I received a shipment of 126 plastic ties, rail joiners and 500 SS track screws last Tuesday.

Each case contains 42 ties with the tie plates molded in and the screw holes molded in place.

Here’s what the individual ties look like. This particular has been outside for two years and seemed to do well in So. Cal. sunlight (UV), heat and cold and rain. You can see the molded ties plates which automatically set the track gauge (in this case 7-5/8 inches) AND they tip the rail 1-1/2 degrees inward (per prototype). Works great for curved track panels. This tie is made for West Coast code 1000 aluminum or steel rail 1 inch tall and has a 15/16 wide foot profile.

I started by building a ten foot long section of 30 ft. radius curve track. Went together very easily. This weekend, I’m going to build track-building fixtures with the tie spacing blocks in place. I am using 12 ties per ten feet now, but will add a tie between each of these ties. More strength and will look better.

This will be the extreme end of the shortline using the 30 ft. radius. The drawing I made to survey the city lot shows a 25 fty. radius and will fit the yard better. My suburban lot here in Burbank is only 11,000 sq. ft. (69 wide X 159 deep), so I am cramped for room. By using these samples, I was able to “tweak” the drawing to get everything to work.

Same area as previous photo, in the opposite direction. This track centerline will follow the curved walkway to the driveway and head back down to the rear yard.

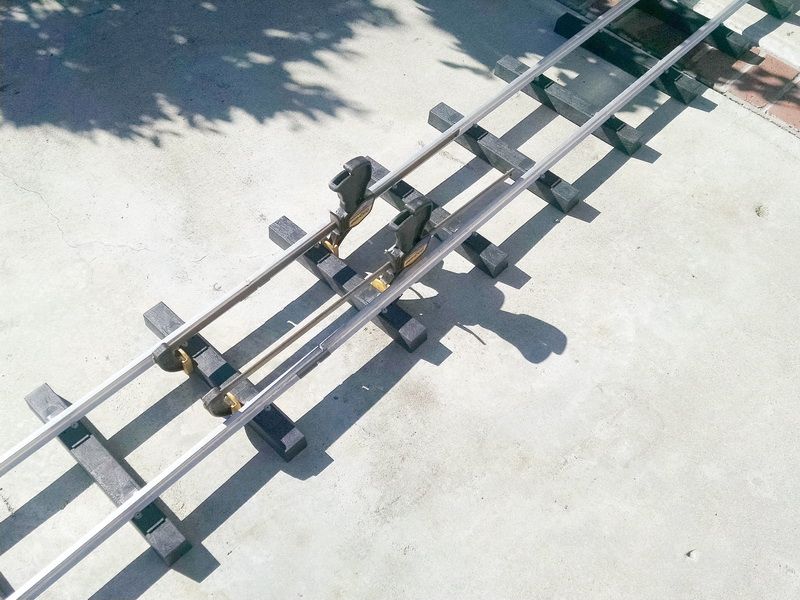

This is a photo of the turnout I will use at the driveway for a small 40 ft. siding. This switch is a #6 with steel points and is about eight feet long. This is now being custom-made at NWF&S Washington shops. Will be shipped by pallet in a few weeks. When the shortline is finished, it will be about 175 ft. long and should keep the grandkids occupied for a little while :).

My son and granddaughter running our two Baldwin electrics and the reefer at Los Angeles Live Steamers about 18 months ago.

Again running at Los Angeles Live Steamers. Since this photo was taken, the new engine (second engine) now has new headlights, marker light and roof is in place, the wood roofwalk is completed and the hoods front and rear are in place and completed. There are still three more cars at home for this train (48 ft. steel gondola, wood gondola and the newly restored caboose I recently posted about. Another car is being built (the Arrowhead Water Bottle Car) I recently posted about.

Granddaughter Aimee with her Dad.

I’ll add to this as I continue building track panels and soon have a “Golden Spike Ceremony”!  That’s all for now.

That’s all for now.

.jpg)