Here’s some more details to enjoy.

The original brake cylinder http://farm9.staticflickr.com/8396/8697863274_2fcf2af203_c.jpg

I chucked it up in my dremel, and turned down the piston a bit to represent a released piston.

http://farm9.staticflickr.com/8417/8697863152_0ab26ca26b_c.jpg

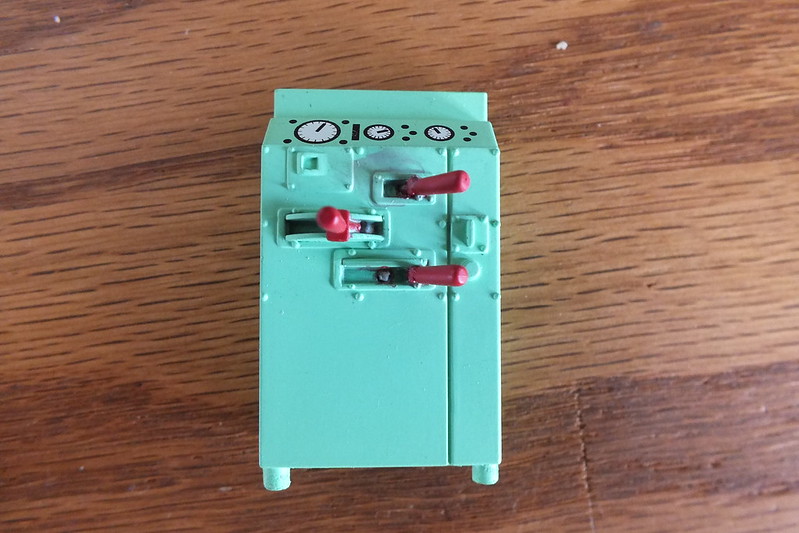

A little more work and its looking better

http://farm9.staticflickr.com/8269/8697862952_c82d78ee7b_c.jpg

Added a brake line. http://farm9.staticflickr.com/8394/8697862588_2314facdea_c.jpg

The sideframes are going to get new brake shoes as well, along with some other details.

And speaking of brakes I cut out the old molded in handbrake chain and replaced it with and actual chain. While I was cutting it out I moved the whole handbrake assemble back into the recess so the handbrake would be flush with the side of the locomotive instead of sticking out as USAT makes it. I made a new weight on the end of the chain with a .080" square piece of styrene and turned it down.

Replaced the grabs with new music wire (.026")

Craig