Oddly, I don’t seem to have a photo of the signal bridge. There are 2 signal brides on the Midwest RAILS modular layout. Each has a stack of electronics to run it from reed switches, but that requires you have a magnet on each train.

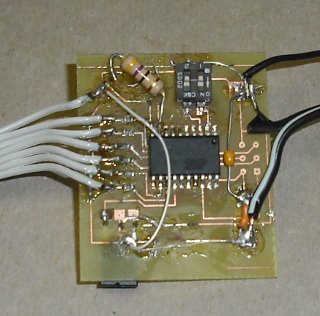

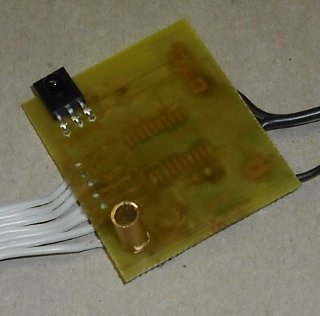

This has an IR sensor to detect the train and a processor. When it sees the train, it changes to red. When the train has been gone 5 seconds, it changes to yellow for 20 seconds, and then back to green. Switch 1 is the direction switch. The signal bridge has lights on both sides. The board holds the “wrong way” side RED. Switch 1 reverses the “wrong way” according to what direction train is running at the time. Switch 2 is the test switch, and disables the timers. In test mode, it shows green unless it sees a train, then it shows red. Test mode is for getting the optics adjusted. In getting this prototype to go, the only hitch I ran into is the IR sensor (3 pin black thing) is VERY sensitive. If there’s any way IR can leak from the LED (inside the brass tube) to the IR sensor, it gets solid positive. These nearly microscopic surface mount parts are surprisingly easy to work with. For those tiny resistors, I tin the pads then hold it in place with a tiny screwdriver and touch my plain old Wal*Mart style 25 watt iron to each end. You can feel the solder melt and the part shift into place. For the IC, I carefully lined up the pack and soldered one corner pin while holding it down with my tiny screwdriver. Then I examined the pack. It was easy to see if it was aligned right, and took only a nudge while heating the pin to adjust it. Then I just touched the corner of my soldering tip to each joint and applied a touch of solder. I only had one solder bridge, and that was easy to fix with a piece of solder braid. Now that it’s working, I went back to the PC board artwork and took care of the “green wire” (It’s actualy white) and put pads to replace that huge resistor with a surface mount one. The mysterious 6 pads on the right is the programmer connection.