This wasn’t started during the lockdown - the PDF instructions are from 2016. But I decided that it would be the first thing to get finished while I am housebound. It was a ‘shoulder season’ project - in the spring when it was almost time to head back to MD it was the go-to when I didn’t want to start a new big project.

The “kit” was a box of laser-cut wood and cast metal parts from Ozark. I ordered it at a discount when they were first released. The kit was invented by Carl Malone (who fortunately was fairly easy to find when I had questions!) Ozark added their own metal parts (which weren’t necessarily the ones Carl used) and their instructions were skimpy. Carl sent me a lot of photos and better directions.

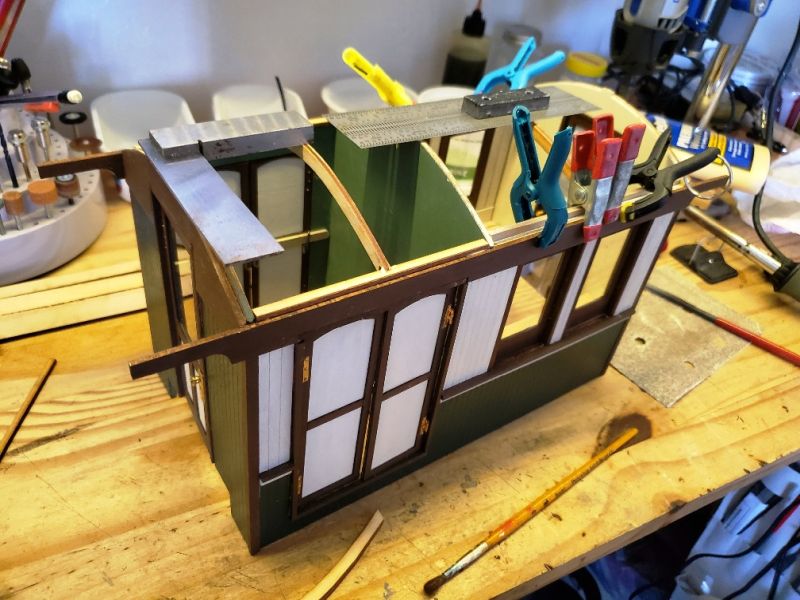

In my experience, painting as much as you can before assembly is the way to get a neat result. You just have to make sure the glue points are clean of paint, as wood glue works best when the surfaces are wood-wood. So last year’s work resulted in completed sides of the coach. You’ll notice it is missing a small piece of paneling - no problem cutting something to fit, but figuring out which paint I had used 2 years ago was fun.

My first task was to sort the metal bits and paint most of them flat black.

I actually soldered the axle journals together, (careful not to melt them too much!) as there was so much metal and that makes a more robust joint. The instructions suggested gluing them to the wood, but I opted to screw them in place. I also added ball bearings, which were such a tight fit on the axles I had to spin the axles in the drill and smooth a fraction off. I added the brass wire to reinforce the mounting. With the screw holding the end I can remove them and get the wheels out if I need to.

So by mid-March the body was glued together and fitted on the frame which now had wheels. The body is loose, so I ended up putting a couple of very small screws into the ends by the steps to keep it together.

.jpg)

I finished the interior and the roof (nice to be able to use proper tools on these big models!)

and then found I couldn’t get the body to snug down on the frame. After much anguishing and inspection, it turned out that one bench seat was too low and was stopping the snug fit. Easily fixed.

And that, as they say, was that. I fixed my freight doors (see separate thread ending in Grrr . . .) and added all the other detail parts. Then my cordless Dremel dropped off the shelf (= was knocked off by clumsy me) and crushed one of the flimsy metal railings. Sigh. It’s back in shape but not as strong as the others.

And here’s how it looks next to my Regner Chaloner which has a 7/8ths driver as it was a pretty small loco in the first place.

(P.S. I don’t really have space for it, so it is for sale. PM me if you are interested.)