I needed something to do inside since we are in some really nasty heat & humidity here the last few days.

CVSRy Porter #3 has been out of service for several months. Somehow I screwed up the RX linking and my transmitter would no longer talk to it. I wasn’t smart enough to add an external bind switch when I first installed battery power many, many moons ago. This was my first autonomous battery powered loco. I it debuted at ECLSTS the year we gathered after at Dave Marconi’s. I have no idea what year that was.

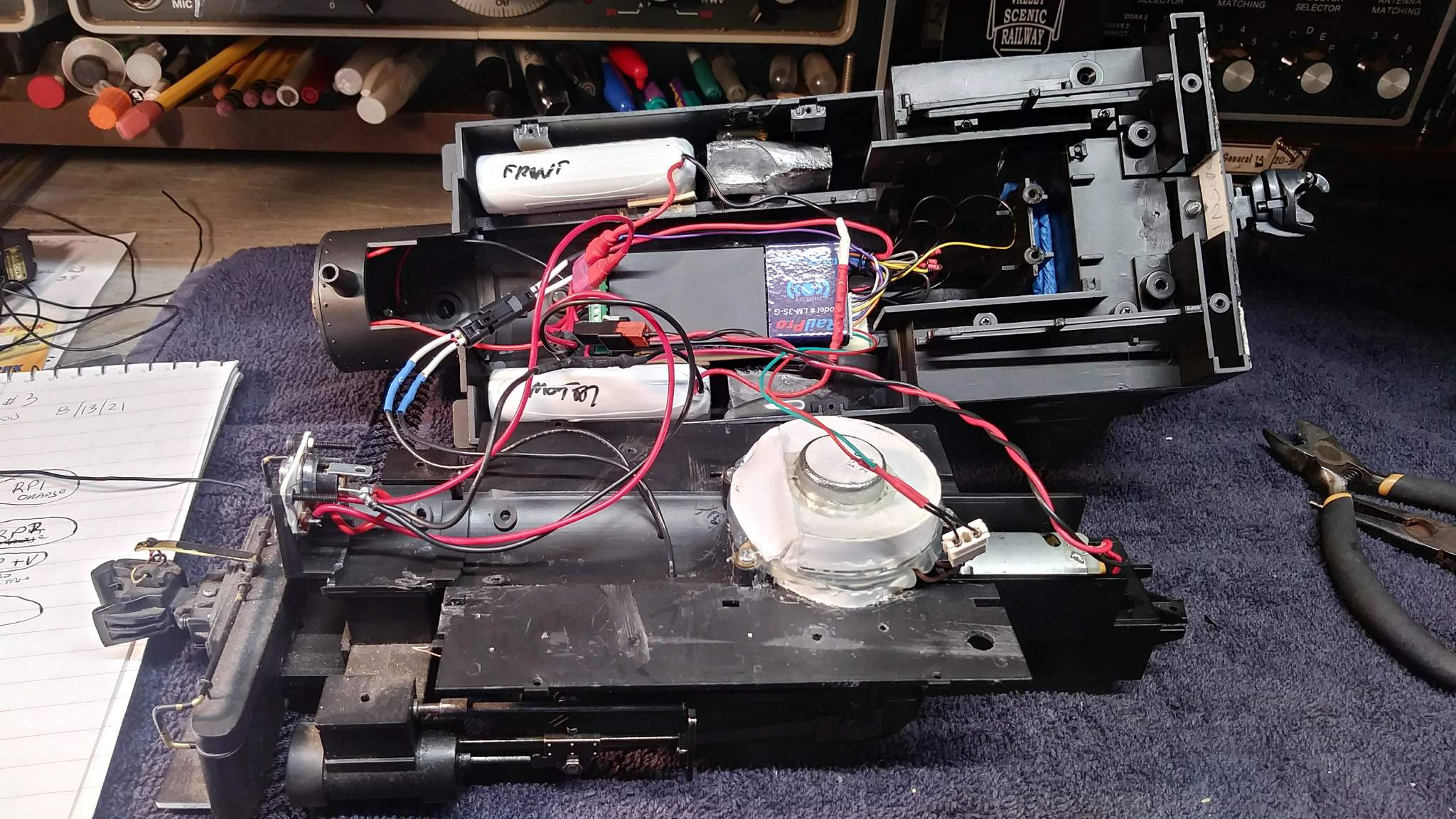

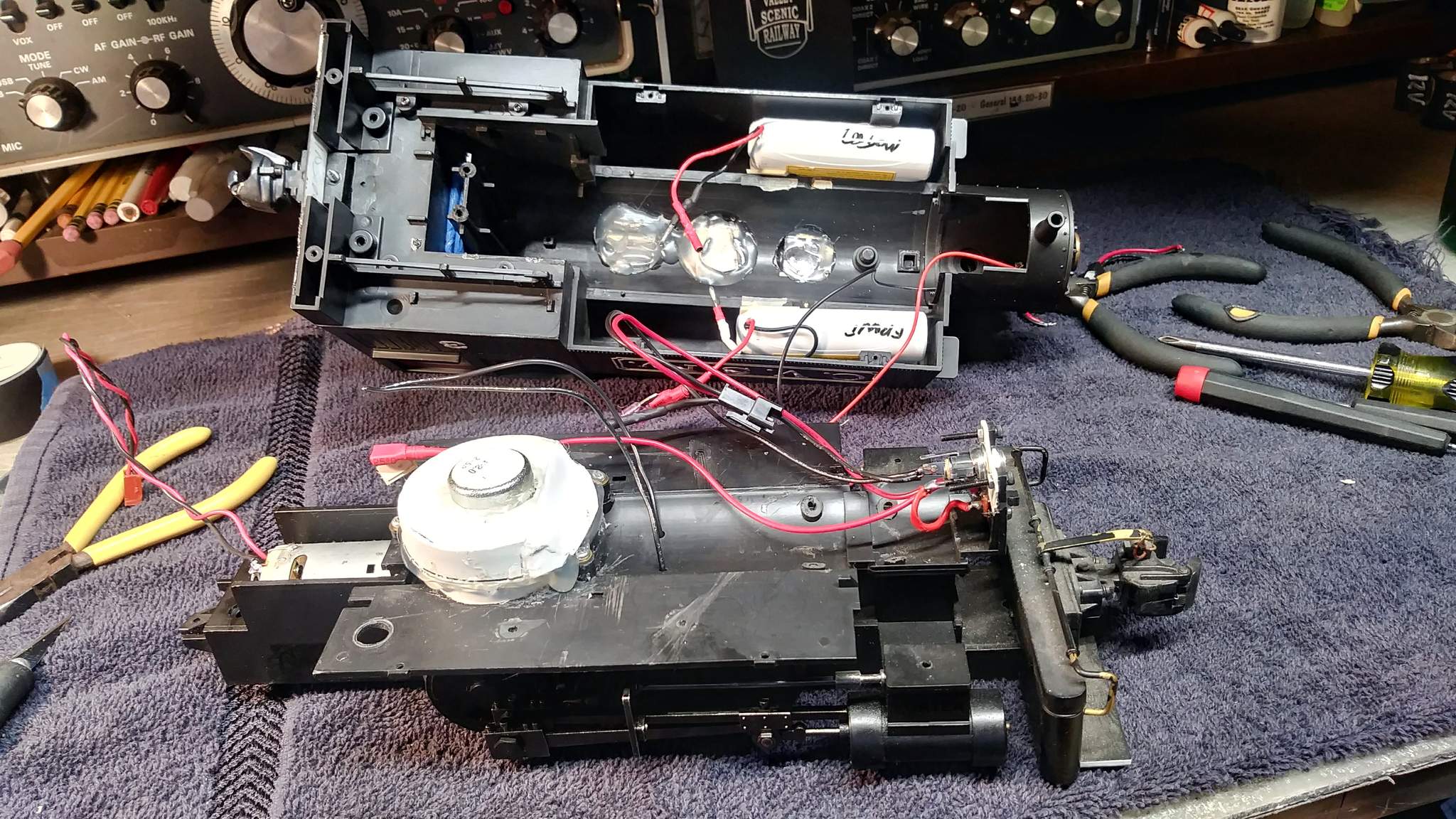

Since I would need to open the loco up entirely to bind the RX, I decided that it was time to install the RailPro board that was purchased for it months ago. Step one, remembering how to open the loco. Fortunately I left myself a little note underneath to alert me that I needed to open the gear case to access a screw that normally protrudes through the cover, but on mine does not. This shot was taken just after the sucessfull opening…

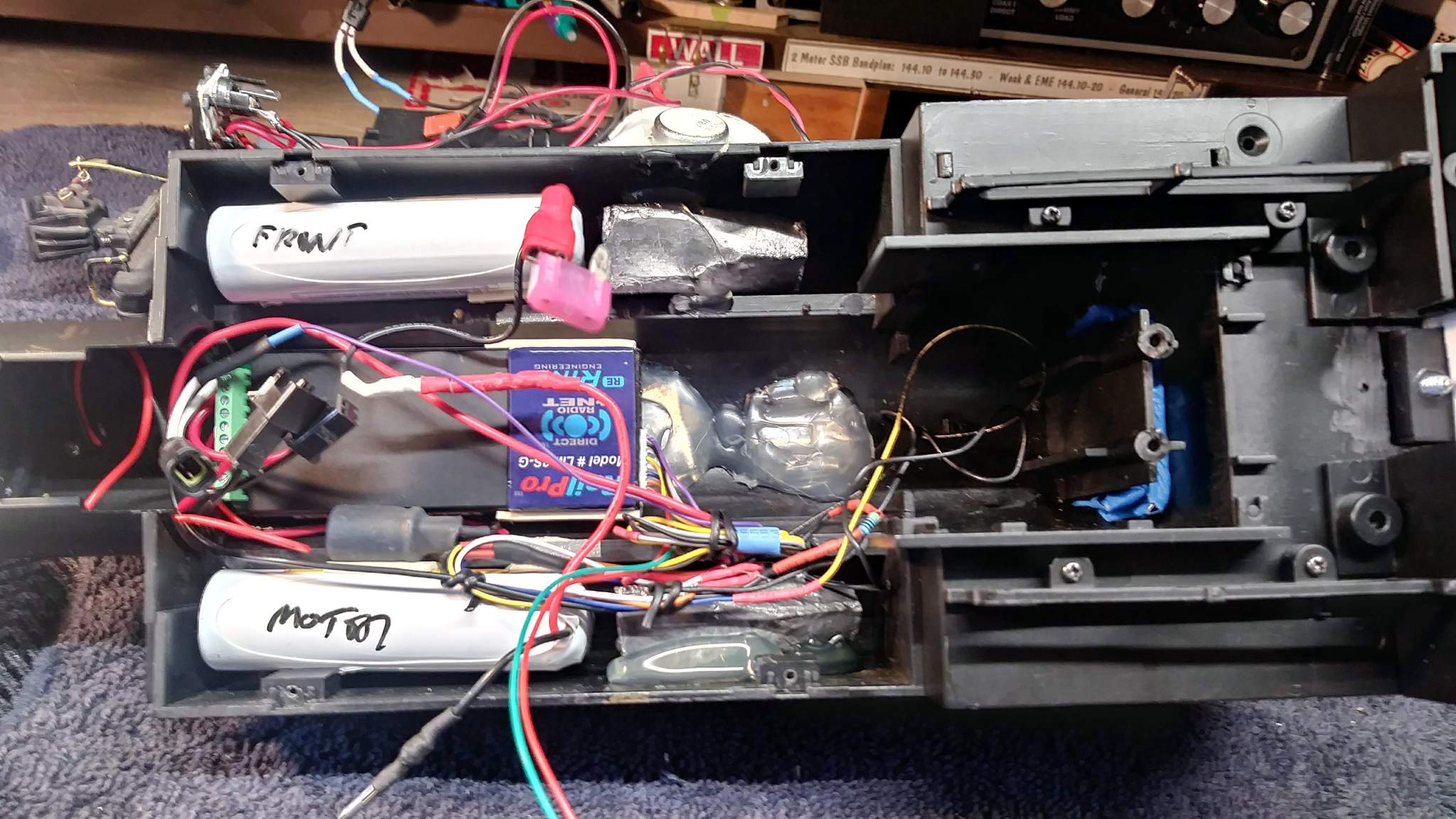

It’s hard to see in that shot, but everything except for the sound board controls are on plugs to allow the shell to be easily separated from the chassis. I made fast work of removing the old system…

While the loco is apart, I’m adding a rear light above the cab and an interior light for the cab. Before I finalize the RailPro wiring and button things up, I also want to add some lead weight in the tanks behind the batteries. Not sure if I’ll work on that tonight, or leave something to keep me busy tomorrow as the heat wave continues.

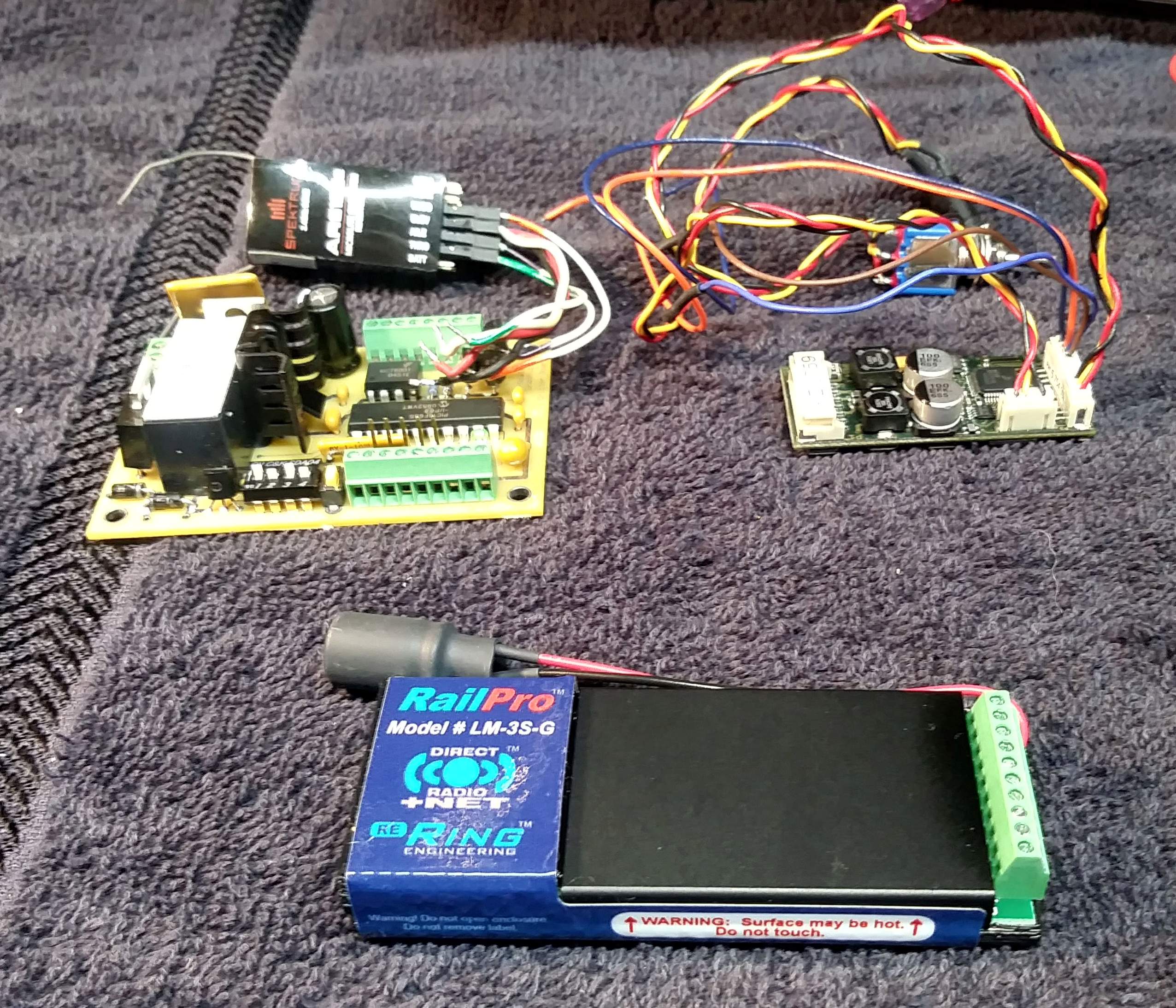

Below is a comparison of electronics. At the top of the picture is everything that was crammed in the boiler: Spektrum Receiver, RailBoss control system and a Phoenix sound card. All of that is replaced by the single RailPro LM-3S-G module. That is a lot less complicated EXCEPT, RailPro only has screw terminals for power and motor leads. Everything else like chuff input and light outputs, needs to be soldered to their wiring harness. This makes the install more complicated than it needs to be.