The next project on my desk is to make up my Regner Heisler kit. I took a few photos for your entertainment.

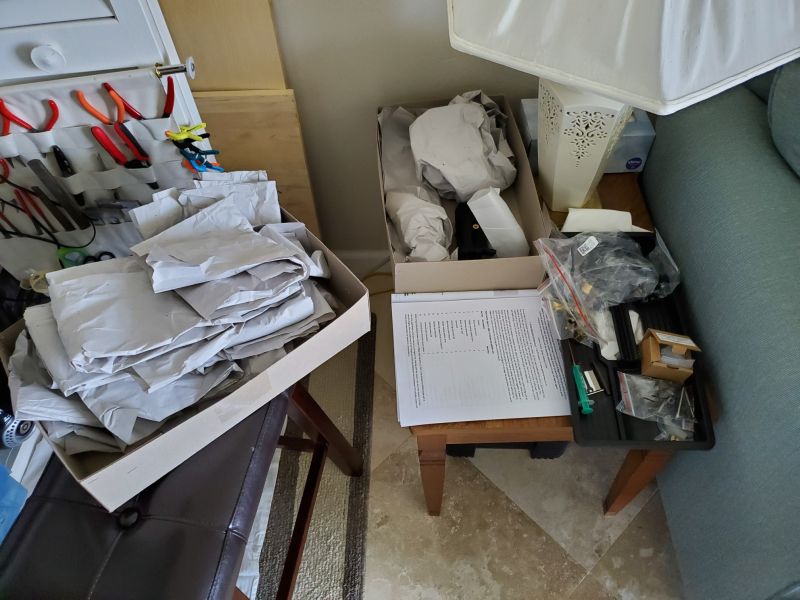

It comes in a plain box and all the parts and bags of small parts are wrapped in paper. On the left in this pic is the stack of wrap. Big parts (cab, etc.,) in the other box, and smaller bags and stuff in the tray on the right. I luckily got my hands on a set of instructions in English from the UK dealer, though I got the kit from The Train Dept.

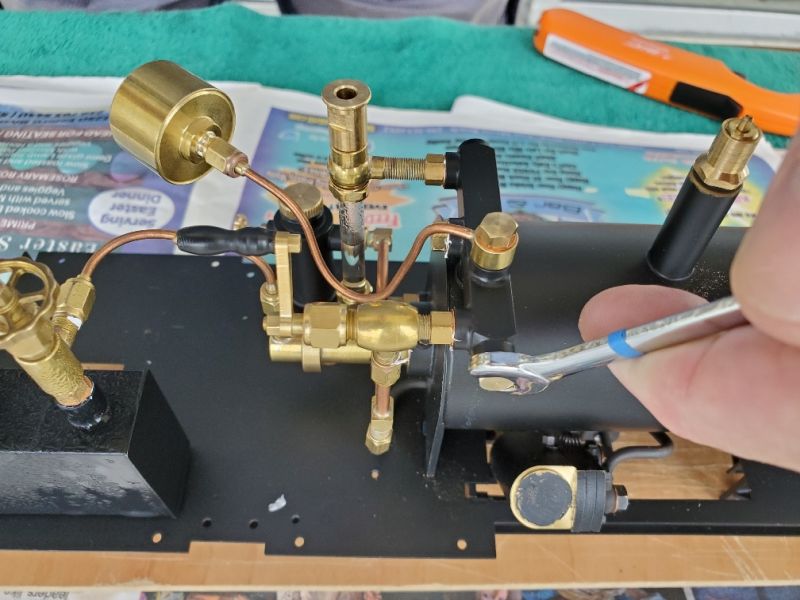

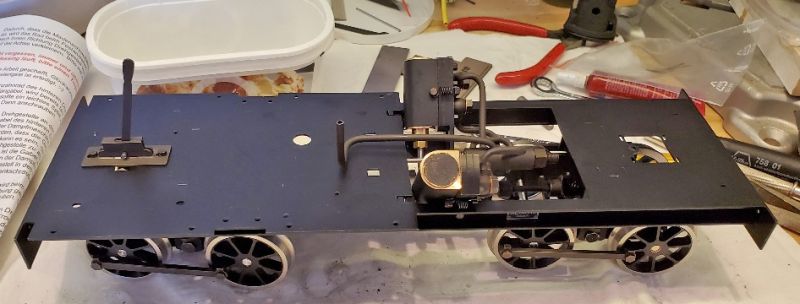

The first 3 steps are to attach the steam pipes and reversing valve to the pre-built cylinders, then bolt it to the chassis. The 4 steam pipes were a struggle to fit, but they went in eventually. I included this pic so you can see the tools I’m starting to accumulate next to the project area, and the myriad of parts for the next step - trucks. The tube is ‘thread locker’ as all those universal pins have to be screwed in and it is best that they be locked. ![]()

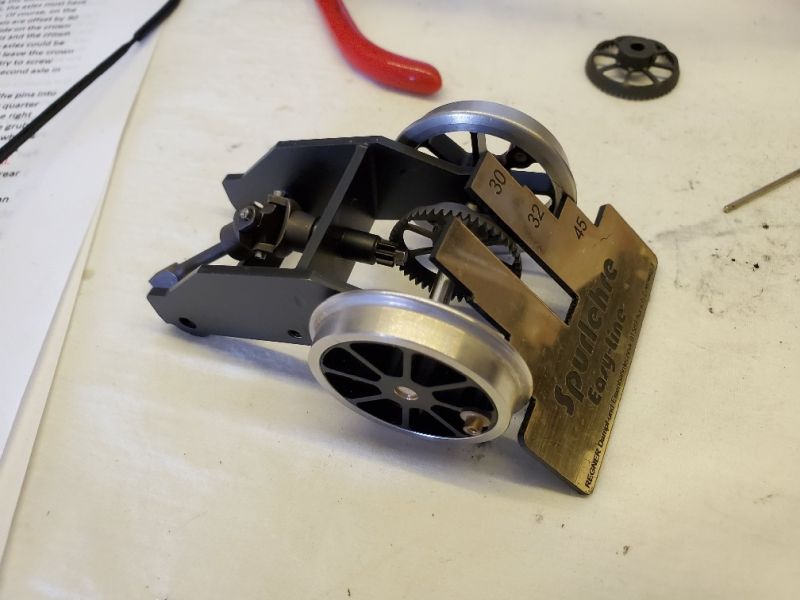

With the trucks under way, I got out my Regner wheel back-to-back gauge. This is a very useful tool when your wheels are just held on with setscrews - the screws tend to let the wheels move occasionally.

One comment from the UK dealer was to make sure there was a little play so the frame could expand when it got hot. There were several places where the paint obstructed the fit (I couldn’t even get the steam dome to sit over the safety without clearing the paint in the hole.) In this case, I put some 320 grit emery on the bench and rubbed the paint off the back of the wheels to give myself a little more play against the sideframes. In this pic 2 wheels are done, and 1 is halfway. I also sanded the paint on the truck side carefully. I ended up with wheels in gauge and a tiny bit of play from side-to-side.

Quartering the wheels and rods, so that one side is 90 degrees different from the other, was easy, as you can see through one wheel to the back of the spokes on the opposite wheel.

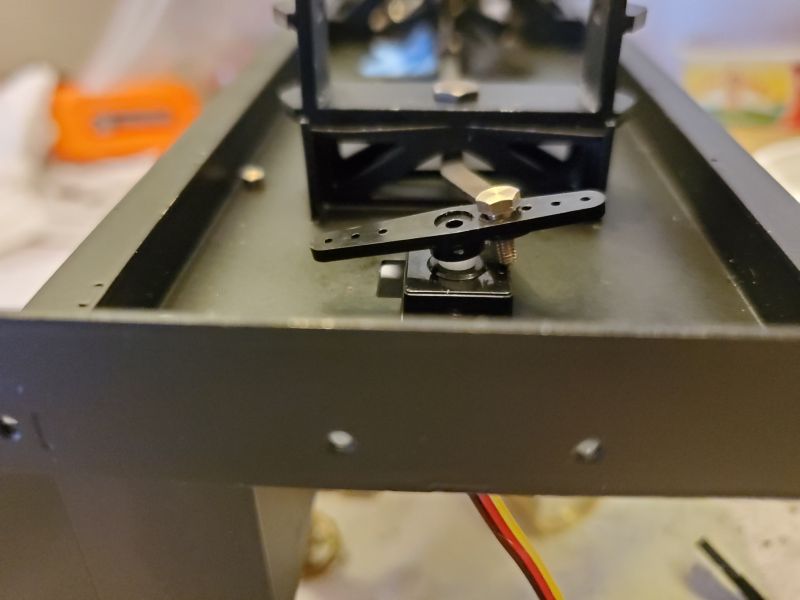

With the trucks on, you are then supposed to contort your fingers to reach the reversing rod bolt above the truck and between the frames. A fiddle but not too difficult, as the hole is threaded so you don’t have to hold a nut at the same time!

And here we are ready for an air test. Feed air in to the steam pipe in the center, and the engine should spin. (A little oil all around also helps.) It did, though only in one direction.

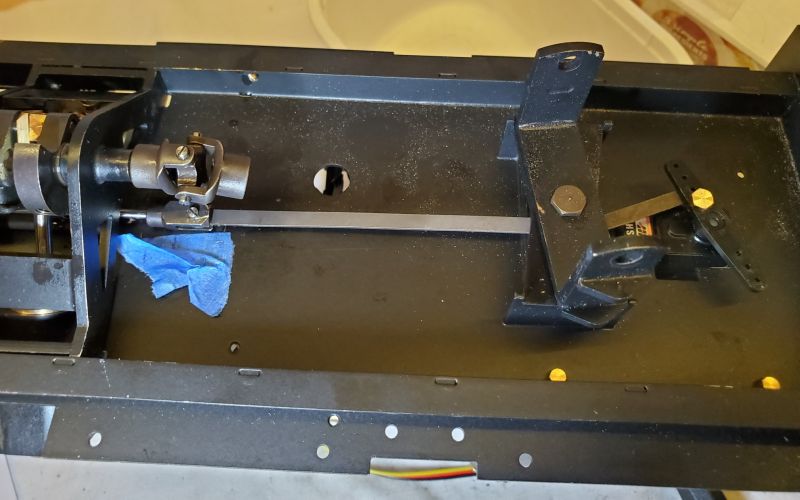

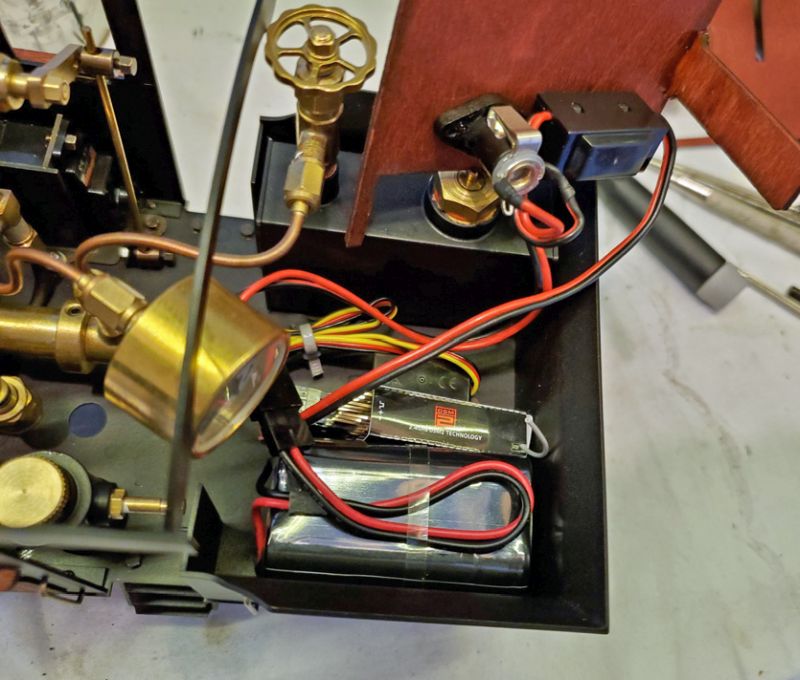

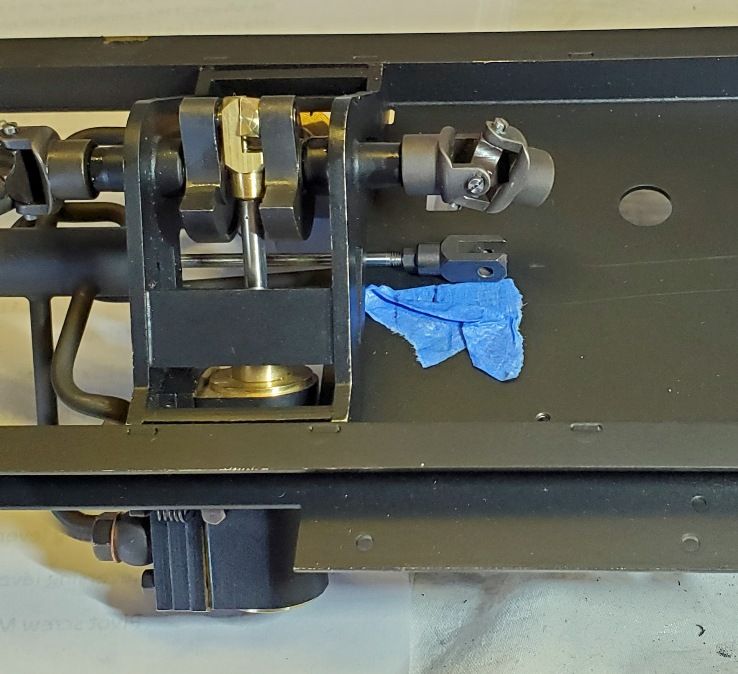

As the reversing rod seemed to need some adjustment, I removed it and tried the air test again with some blue tape and a handy marker. In this pic the 2 black marks correspond to the position of the start of the threads on the rod for fwd and reverse, which were easy to find with the tape and the engine upside down. I didn’t re-fit the rod, as I am waiting for the R/C kit to arrive.

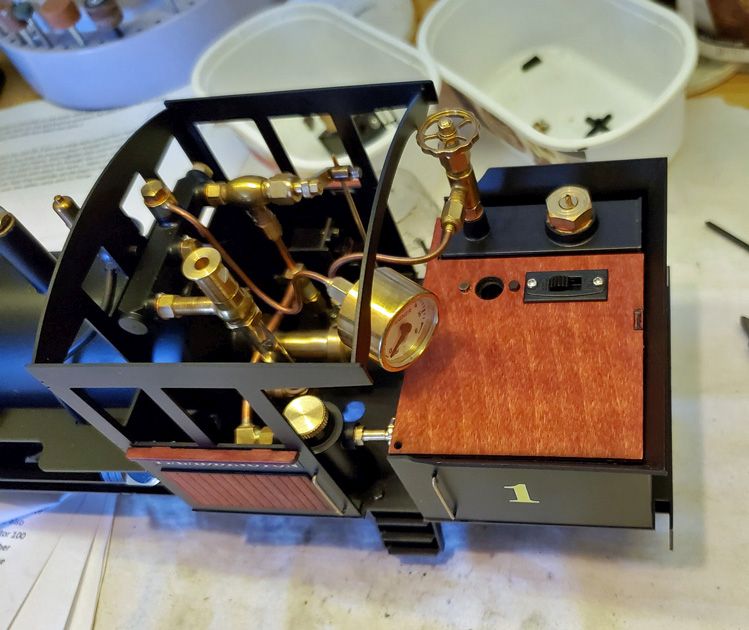

A potpourri of boiler fittings ready for the next step.

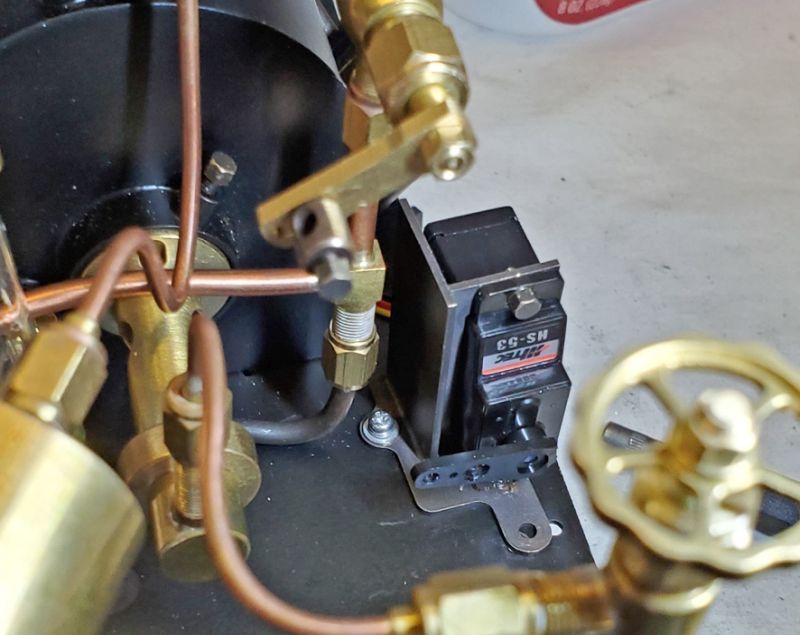

After a lot of careful fitting and bending, I got the various parts in the right place. My instructions said it could be steam tested, so that’s what I did. I left the trucks off, as there are plenty of parts to be fitted from below.

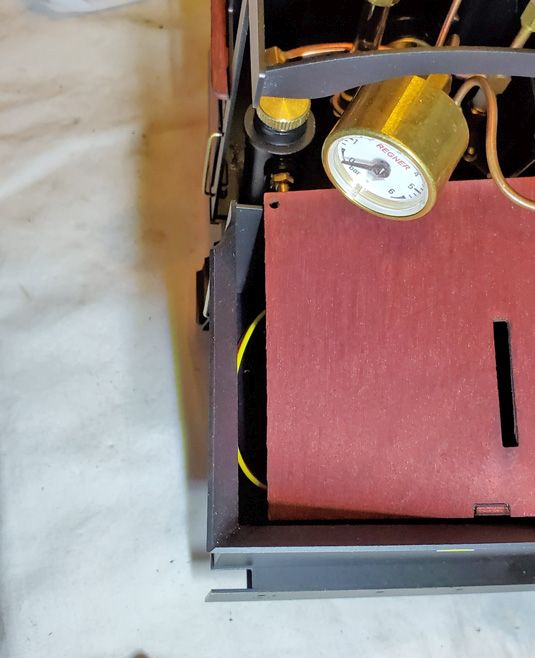

You get the pleasure of installing the meter screw in the lubricator, and I didn’t see an instruction telling me to back it out 1/2 turn or more before steaming. The other thing I didn’t see was the 3rd blank plug/bolt. You can see the one on the boiler above, and the one on the back of the steam manifold. Once steam came up it wafted out of the hole in the far end of the manifold - the side away from me as I did most of the work this way round.

Anyway, the bolt was duly fitted and the steam test was successful.