Steve Featherkile said:

That makes sense.

What happens after the first rain storm? Or don’t you worry about that? Doesn’t the paper get in the way of a bond between the ties and the plexiglass?

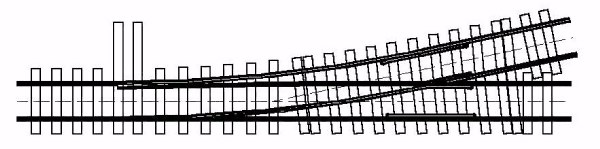

I’m trying to sort this out because I want to build my turnouts. The storebought ones are too spendy.

SteveF

Steve,

The first turnout I built was on PT plywood. Left it out in snow, rain, freeze, thaw, very hot summer weather and other than weathering that turnout is the same as several years ago when I first put it out there. Spikes didn’t move, rail is in gauge etc. etc. Can’t ask for more.

Since I don’t want to use PT ply on the ground, I got a test piece of PVC (only 4mm thick) to try out the adhesives. Tested again and the results are excellent.

I’m using Weldbond for adhesive and the stuff penetrates right through the paper since I put down the ties right after I glue the template. Generous application of glue!

In addition to that the spikes penetrate more than 1/8" into the PVC. And the 6mm (1/4") PVC makes a very good base, drainage holes (if required) are a breeze, mounting throw mechanisms is not a problem.

Yes, it depends on the climate, tests tell me it works in our climate.  Since I like things as maintenance free as possible, I test first.

Since I like things as maintenance free as possible, I test first.