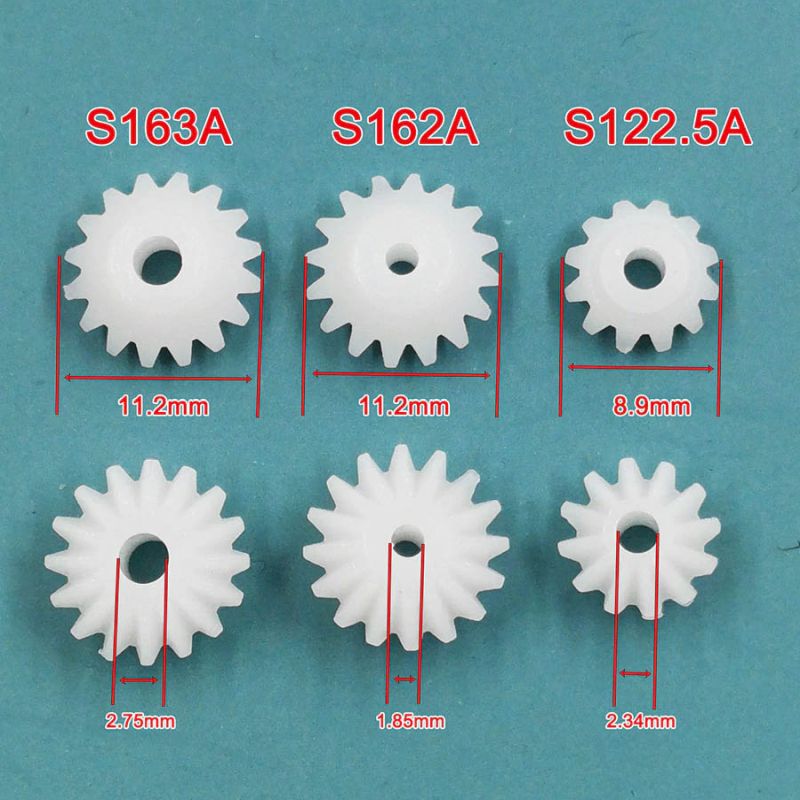

Just thought I would entertain you with a photo essay of the fun I am not having with the rear axle on a Bachmann Railtruck. My Railtruck is actually working, as is my friend’s unit, but the axle gears break. I happened to find a vendor on aliexpress selling 5,000 bevel gears for $101 which looked about the right size, so I messaged to ask if they would sell me a “sample”, so they offered me a pack of 10 for $0.42. I had just bought a gear puller and a wheel puller, so I went ahead and bought 3 different sizes thinking I’d be able to address the problem when my axle failed.

About that time someone piped up on Facebook asking if there was a way to fix a bad gear. Then the guy who sold me my Railtruck offered to sell a spare but working axle, so I hastily bought the spare and promised to investigate swapping/fixing gears. Mr “Gear Man” Jerry indicated he couldn’t cut bevels on his equipment, and his 3D print doesn’t seem to have worked. So the ball was back in my court.

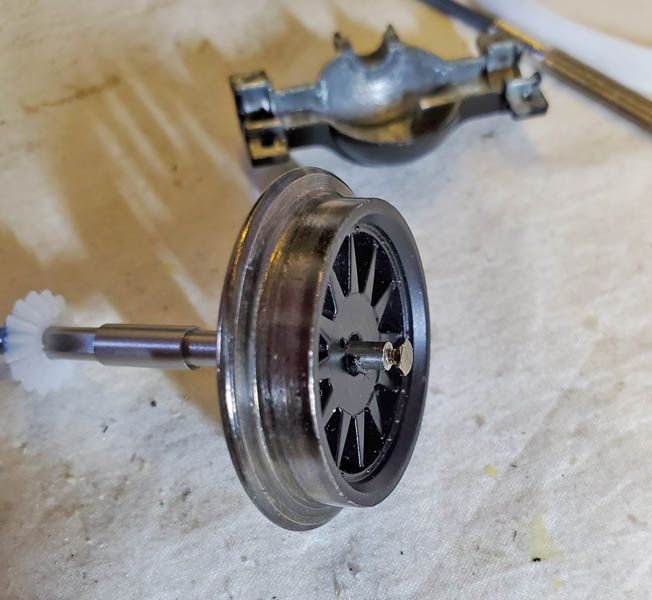

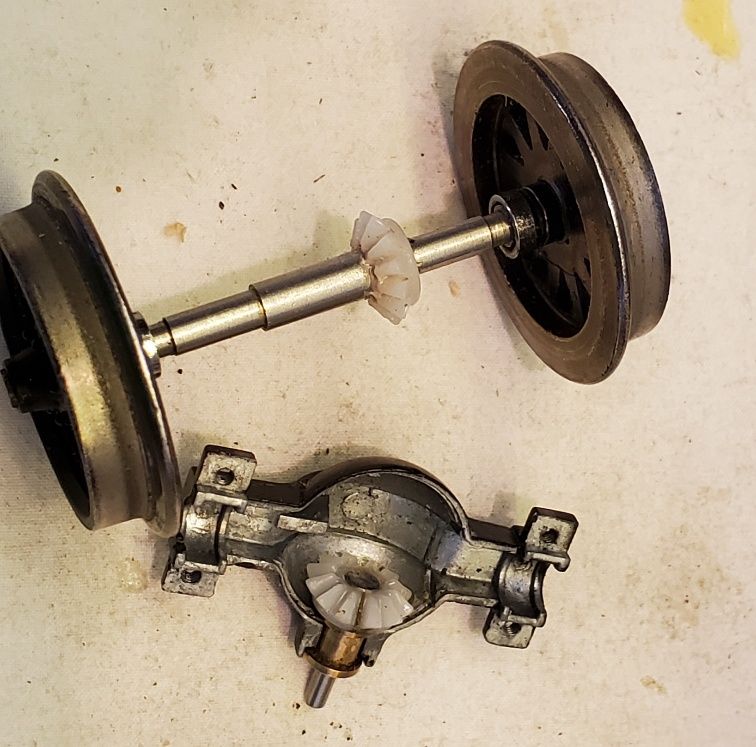

I took this pic shortly after I got the axle so I could give Jerry the dimensions.

A few days ago my samples arrived, and as the Boxcab is essentially finished, I made this my next priority.

The gear in the axle is 10.5mm diameter, and these are claimed to be 11.2mm. That’s a mere 0.3mm to be sanded off. I set the gear in a rig made from a pcb stand-off and held some emery to it while it spun in the drill.

I then tilted the drill and cut off about 1mm in thickness using a small saw (about the size of an Xacto blade.) The originals are 3.5mm and this was 4.5 - not any more.

Then I got out my new gear puller ($5 at Aliexpress,) and pulled the gear off the drive to the axle.

Once it was off, it was clear it had 2 flat sides, as suspected. The axle has flats so it seemed likely they would be the same part.

Here’s the Bachmann gear and my new gear, with a little fuzz from the sanding. The new gear has a 2.9mm hole, whereas the old one has a 3.2mm with the 2 flats which are, surprise, 2.9mm apart.

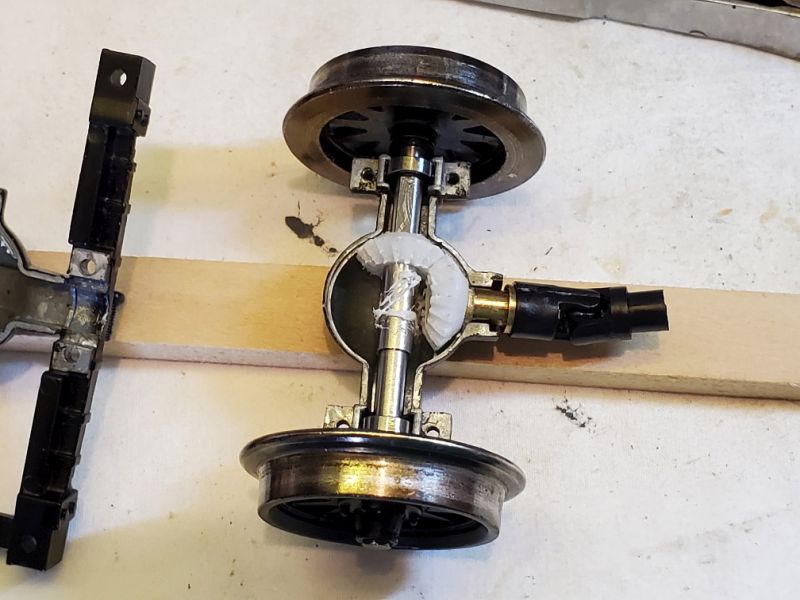

The gears will actually mesh, sort of, and using a new gear in the axle and leaving the old one on the driveline may be a fall back option.

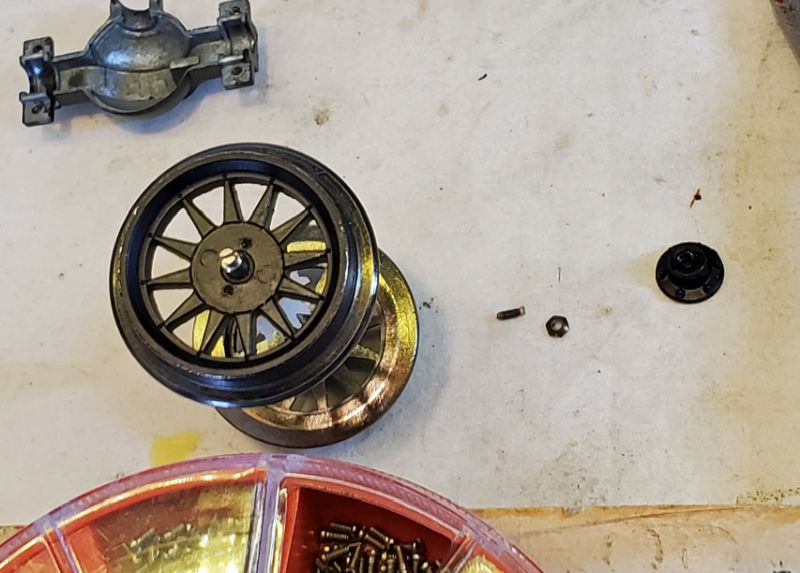

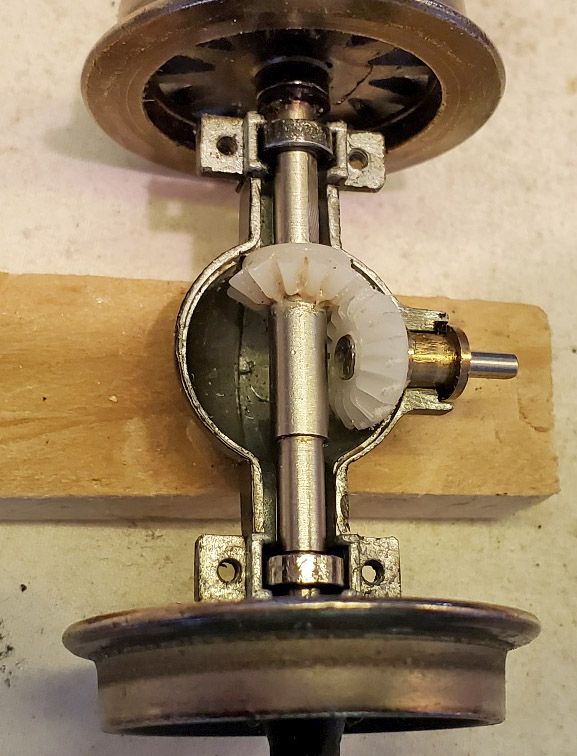

Having dealt with the driveline, it was time to remove the axle gear. First the wheel puller:

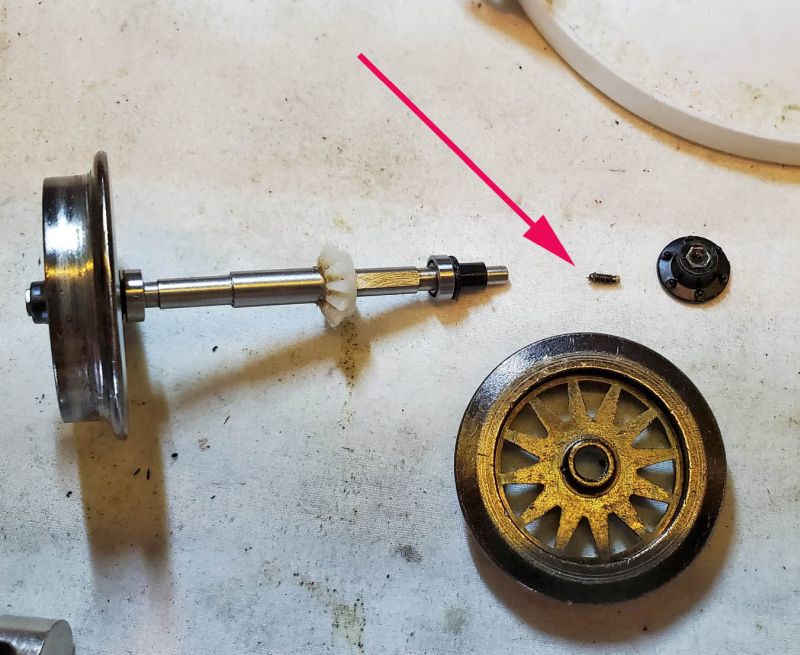

There’s something odd here, as the axle end looked like solid steel - but it wasn’t. There’s a plastic overlay hub, and a tiny, tiny (m1?) bolt in the center (arrowed.) And the wheel pulled off the insulating sleeve.

So out comes the gear puller again, and I got the hub off the shaft.

As you can see, the axle is splined to hold the wheel hub. I’m not sure what holds the wheel on the insulation - probably glue. I also discovered the bearings are nice little ball bearings.

You can also see that everything tapers to the outer end, so that the gear can come off. The trusty gear puller, using the axle as the pin, managed to pull it off with no fuss.

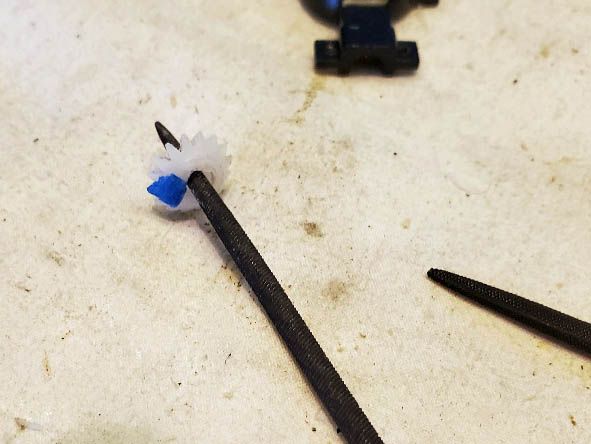

I then drilled out one new gear hub 1/8", which is 3.18mm. It was a little loose on the shaft, so I may have to junk that one - though I could pin it on the flats. TBD. Here’s the new and original gears again.

My final process before dinner was called, was to file the center of the other gear with a mini round file to make it an elongated 2.9mm/3.2mm hole, which I could then force on the flats of the axle and drive shaft.

At this time it does not yet fit either axle or drive shaft, but when I get a minute I will continue to file away at it.

I an tell you one thing - I will not be offering to fix anyone’s broken axle gear. I will get a broken one and fix it just to see how easy it is when I know what I am doing.

Anyone want their broken Railtruck axle fixed? Message me.