Hey all,

I have been trying to figure out how to post of pictures inside the reply (not quite there yet). I did post an album that has the pictures I would add (if you hit my picture I think it takes you to the albums). I know it is a pain, but you can see the album at least.

Pete - not my posting on facebook (I do not have a facebook account) with the white packed grease in the gears but my trucks looked like that but a bit more yellowish and the grease had the consistency of melted birthday candle wax.

Now that I cracked open the gear box, I realize there is more to the story than meets the eye.

- Purchased engine was very dirty on the outside and as indicated the trucks looked like they were full of goo.

- Cleaned the engine and manually removed the goo with dental tools. All four of the worm gears were in good shape at that time. (If you look in the album, the 3 ate up gears looked like the one good gear remaining)

- I did the truck to frame connection mod as from the GIRR.org tips page.

- I ran the engine on my a track with Bachmann E-Z riders for about 30 minutes. I noticed it took a bit more to get it going than my other climax. I figured it just needed to break in a bit.

So I ran it on my outside Christmas display (you can see my log train in the album pictures)

- Ran for about 4 hours with no issues. It was run at a moderately slow speed but required more voltage to pull the train than my shay needed.

- There is some grade to the log train track but not huge

- After I ran it with the log cars I at the end of the night I took the cars off and ran the engine. It made it about half way around my track and stopped.

- I just blew it off thinking is was dirty track or a leaf etc.

- I felt the trucks. They were slightly warm but not hot.

- Next time I went to run it it would not move.

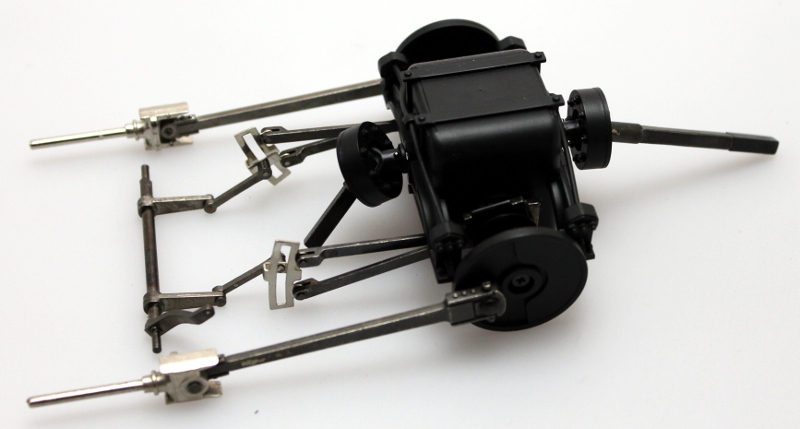

After you asked for pictures is when I removed the trucks and looked at from the bottom, but the real destruction was not seen until I removed the trucks and opened the top. (look in the album for the pictures of the trucks)

One truck has had work done in the past as I can see black colored gears in it like the ones that come from NWSL.

I have no idea what tore up these gears.

I wonder if the goo was still in the trucks and was bogging them down or it was stickier than I thought where the axles when through the truck wall.

Did they overheat eating up the gear, does not seem likely as it is only the worm gear that is damaged.

Still need to replace these gears. I am hoping as others pointed out that I may be able to cannibalize a couple old 4-6-0 chassis I have for the gears…we shall see.

As I am dumbfounded at both why this happened and what to do next I am looking forward to your thoughts.

Thanks

Jerry