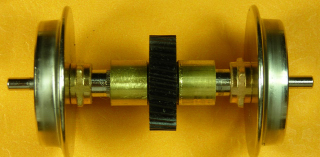

If it has tapered wheels, it cannot have projecting axle tips as Paul posted (and that picture is a USAT axle).

If it has the tapered fit wheels, then there are screws in the center of the wheels.

“new style”:

Old style with axle tips that go into sideframes:

Anyway, virtually all Aristo locos have incorrect wheel back to back, the picture below shows a result of insufficient back to back setting:

The wheel tread is lifted from the rail head.

The worn wheel theory does not make sense, you would have to wear off a huge amount of metal, since it’s the back side of the flange for a fair distance “in”.

38 mm is 1.5" too tight… 37 mm is way off… and you need to measure not at the tip of the flange, but the flat back of the wheels.

Still would like to see EXACTLY what you mean by cannot negotiate through the frog… I have shown you one example. If you try creeping through the switch and taking a picture it should show if you have tight gauge, bad flangeways, bad wing rails, bad wheels, etc.

You took it inside and it was fine, so you could start by comparing the 2 switches, the gauge through each, but the RS-3 is a touchy beast, there is not a lot of flexibility in the pivoting of the trucks, and many people will cut off the bolster rib on one end to help.

Greg