Sometimes you find an Aristo-Craft coupler that’s hard to couple. It works, but you have to really slam it 3 or 4 times. The usual problem is the knuckle has to be pressed in too far before it will latch. The coupler is simplicity in itself. Two screws hold the bottom plate on

Remove the bottom plate. The spring loaded latch will come with it. Now, for the explicit gory insides.

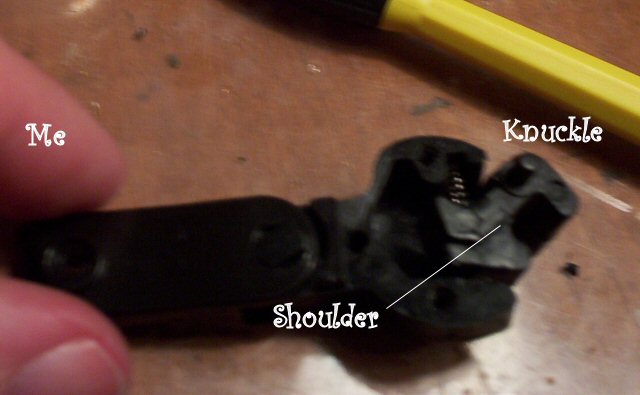

Annoyingly, I have a beautifully sharp photo of my tiny screw driver. There is one moving part and a spring. Notice the shoulder. When the coupler is open, the latch rests on the part above the shoulder. When closed, it drops to the lower part locking it closed. All we need to do is trim off a bit of the shoulder so the latch drops when the coupler is just a little more open.

Just be careful which knuckle you’re trimming!

Reassemble the coupler. The spring goes in front of the screw hole. It’s a bit of a trick, but hook the knuckle pivot in the hole in the bottom place, push the release lever back and down, and lay the plate back onto the coupler. It always takes me two tries. When the couplers are working right, two of them will lock together with just a little play. You should be able to pull them apart just a little. If they lock solidly together, one, or both of them needs to be tweaked. If you have one that pops open, look closely at the shoulder. It should be nice and square. I had a coupler with a little bit of plastic on the lower part that didn’t let the latch go down. It seemed to latch fine, but if you pulled on the knuckle, it came open very easily. The little scrap of plastic was levering the latch up over the shoulder. A sharp knife solved that little problem. I’ll have you know, I dissasembled this coupler, modified it, juggled a camera and put it back together without need for a bandaid!