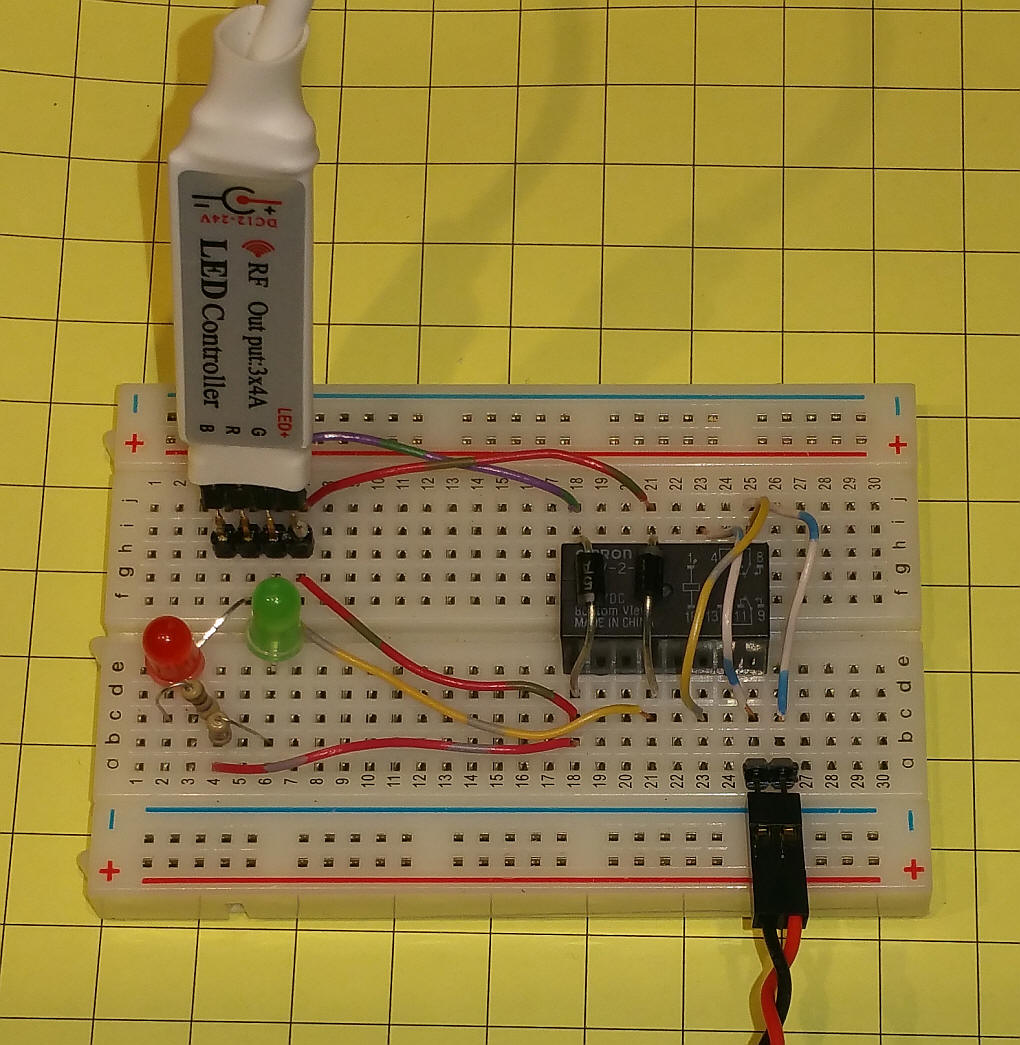

OK I guess I am going to be the one to ask the electronics 101 questions. I was fiddling around wiring this up on a free PCB CAD program and realized right away that I have no idea what I am doing. I would say I feel a little ignorant but I am wiling to bet I am not the only one who might want to do this but does not have the least bit of understanding on how to wire such things. My issue is the relay. I understand that we have a positive and a negative coming from our power source (in my case it will be a battery) into the LED controller (spliced into the big round white wire I am assuming). The that PCB is doing its thing and then has four outputs; A common positive, a red, a green, and a blue (which will have no wire connected to it) which I would understand to be the returns or negatives coming back. That will be plugged into our header. Now here is where I lose it; on the back side we have three wires coming off the header the common +, a red, and a green. At the other end we will have a motor positive and a motor negative (or track if that’s what your powering). In between we have this relay. I will stop here for a second. . .

The relay I think I understand in theory what it is doing. Powered on it has polarity one way (closing one set of contacts and opening the other) and then powered off it reverses the polarity (opening the previously closed one and closing the other). That’s it purpose correct?

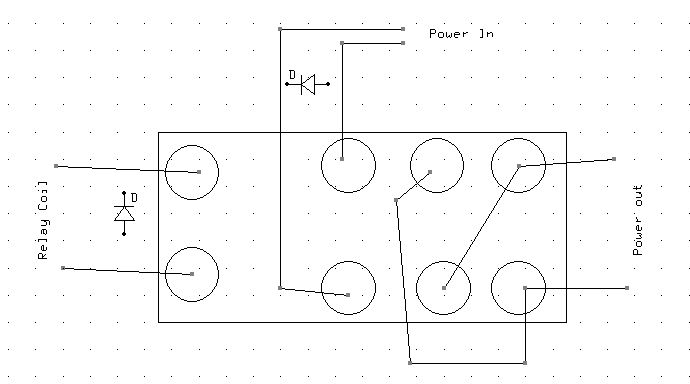

So back to the wiring diagram. Red’s sole purpose is powering on and off the relay. That’s why DIY1 Red is set to max on so it will send full power to the relay. DIY2 Red is set to min that way it provides no power to the relay. So toggling between the two causes the red to energize the relay and de-energize. (just for clarity sake (DYI3 would have everything at minimum so it would effectively be turning the whole works off). In the diagram then I see where the common + goes and feeds the relay and then comes back into the Red return ( I will forget that it goes off to the LED sine that is a visual aid that isn’t actually used in operation); thus completing the red circuit. Now Think I get what it is doing from there. On the diagram where it says NC and NO (twice because it is a Double Throw relay, throwing two switches) and they are separated by a hinged line. That hinged line is representing the switch and the little triangles the contacts right? The Red feeding the relay is causing the relay to throw both of those switches correct?

Now the common + in addition to feeding the relay is also coming into that lower “switch arm” as the + for the motor; and we might consider it the “+ switch”. The green wire which is the motor return of - is attached to the upper “switch arm”, and we might consider it the motor “- switch”. now if I am still tracking in the NC state the right side wire going out to the track would be + and the left wire would be the -; with the NO circuits open. When things reverse and both switch arms drop down (thanks to the red wire and the relay) causing the NO to become active making the right wire - and the left wire +, with the NC circuits open.

So I think I have all that. What I don’t have then is which of the 8 poles on the DPDT relay are going to have what wire attached. Three wires in and two out, where do they go.

Now for the diodes. In the pictures they seem to be integrated into the relay but on the diagram they simply need to connect (directional) between the common + and each of the returns. I am assuming this is done over the top of the relay for convenience of solder connections? Instead of cutting in somewhere else you just crossing the appropriate poles on the relay and soldier both the diode and the wire to the same poles on the relay corresponding to circuit color.

Walking through it I think understand it and just don’t now which leg of the DPDT realy is which. A wiring diagram of that would help and know it is printed on them and I am sure on a spec sheet. So maybe I answered my own question by walking through it.

If I am in error anywhere please let me know.

Now Green is our speed control, we will be using it to actually speed up and slow down the locomotive correct?