I have posted this also on the UK based GSC site, that a number of LSC members frequent, but I thought as the loco in question would be more numerous in the location this forum sees as home it might help to post here too. I’m really looking for this information to give me the confidence to dove into the job ![]() Two bites at the apple.

Two bites at the apple.

I have an older version track powered Accucraft K-27, the one with the right rail pickups only on the 4 tender wheels and the left only on the loco’s 4 driving wheels. The loco and tender are electrically insulated from each other. Apparently this was once a common practice with “all metal” construction model locos. Later versions of the Accucraft model picked up current on both sides of the loco, all wheels. The loco has a functioning Sierra Soundtraxx sound card fitted. Most sounds are voltage activated but the chuff and a couple of other sounds are reed switch activated.

I have the published manuals for both the loco and the sound card. The sound card’s has a full wiring diagram for its own installation but the loco does not. I have searched the web for the latter but to no avail. I did find an old Garden Railways article, authored by Tony Walsham (who posts here too), but it is not clear as to how he (re)arranged the power supply to the motor and isolated the pickups on this specific loco type when doing a similar conversion some years ago.

As I understand it replacing the track pickups’ voltage inputs to the sound card is fairly simple - replace input from track pickups with those from one of the 2 pairs from the electronic speed controller (esc). What I am not sure about is how to isolate the motor (and possibly chassis too) from track induced voltage inputs and how best to attach the esc voltage output to the motor. There is a terminal block, accessible under the ashpan, where a number of wires coalesce for power distribution on the loco itself. I have not investigated these yet

Questions - Am I right in the assumptions I have made so far and how do I isolate the track pickups on the loco (tender is self evident) and correctly connect the motor to the esc without ripping the loco to bits ? Your assistance and suggestions would be most welcome.

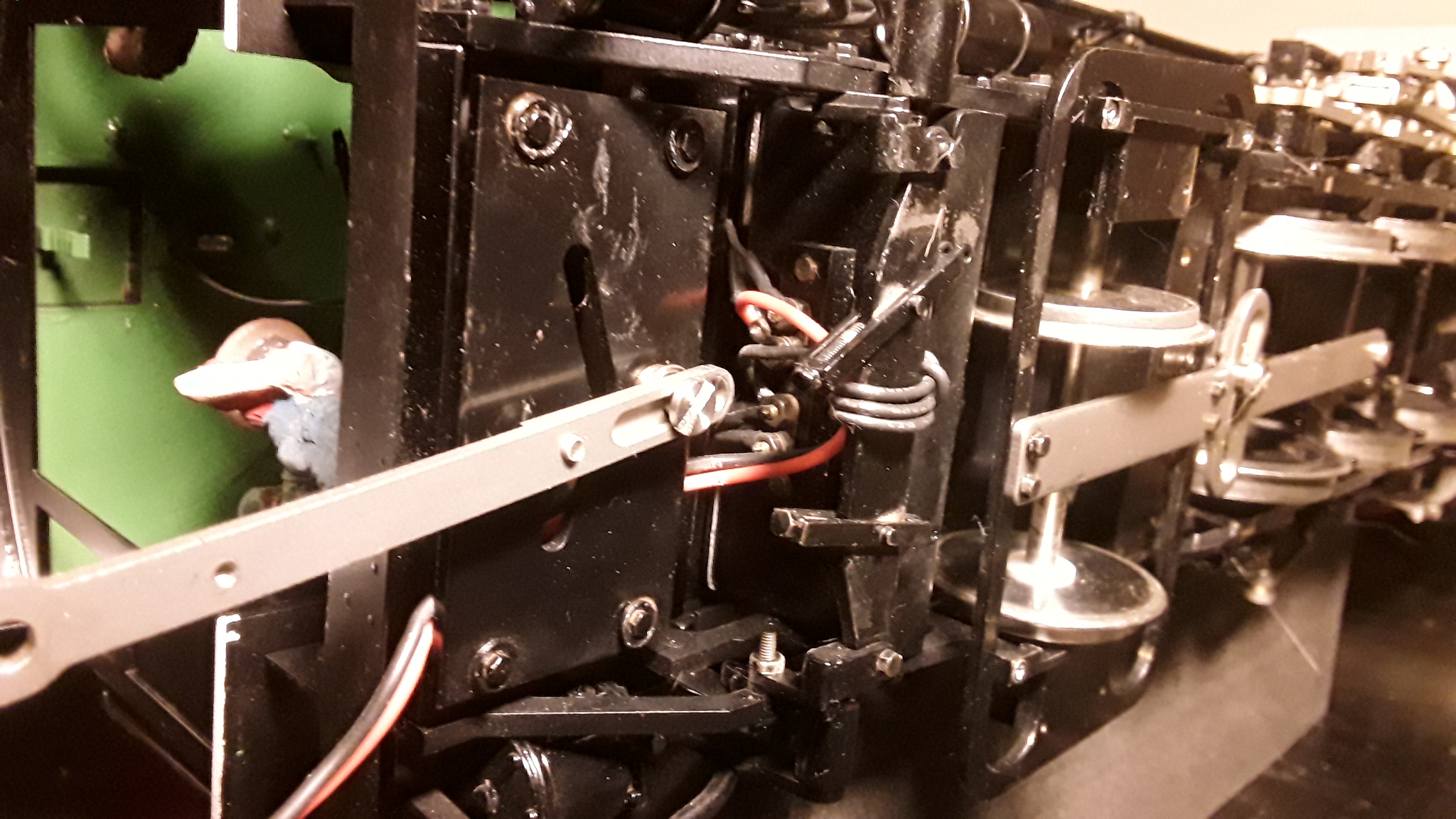

A picture showing the terminal block under the loco’s ash pan. As a point of note I have acquired all the conversion gubbins from UK company Fosworks - A Cobra high frequency 6 - 24v speed controller (made for DC motors), 14 cell AA NiMH battery pack with 5 amp fuse, Omni Tx-2.0 transmitter (nice little palm of hand unit), Omni RX-2H receiver and assorted other parts for charging and wiring.