If you have ever had a problem with a drill bit wobbling all over the place when you need to start a hole, center drills are an excellent solution. Center drills have a stout shank that tapers down to a very short drill bit end that will allow you to very accurately start a hole. They eliminate wobble and scratching of the surface being drilled. Center drills come in a wide variety of sizes, with a number for each size. 0000 is .015 inch drill for really small applications. You can purchase them from any machine shop supply company. I purchase mine from McMASTER-CARR which is easy to locate on the web. They even have coated center drills for use on hard steel. Here’s what they look like (the hardened steel center drills came in a pack of 4 sizes from Grizzly Industrial and the 2 coated center drills (.015 inch and .0020 inch) are from McMASTER-CARR.

On the subject of drill bits, I LOVE my stepped drill bits.

(http://letsmakerobots.com/files/userpics/u5293/stepdrillbits.jpg)

Bob,

Just what I was saying. One idea brings another. I’ll have to check them out.

Thanks for sharing!

I was just thinking of buying a step drill a couple of days ago, and of course already forgot. Thanks for the reminder. I got one today!

I tried out my new step drill on a little styrene project. Wow! It worked perfectly. I was afraid the rather odd design would make it hard to handle on a small piece of styrene, but with slow speed, it just cut like butter, and very easy to control. When using multiple drill bits on the same job, I always ended up with an oblong hole. The step drilled hole is perfect.

Del Tapparo said:

I tried out my new step drill on a little styrene project. Wow! It worked perfectly. I was afraid the rather odd design would make it hard to handle on a small piece of styrene, but with slow speed, it just cut like butter, and very easy to control. When using multiple drill bits on the same job, I always ended up with an oblong hole. The step drilled hole is perfect.

Yep, they are one of the coolest tools I have in my collection. VERY neat.

I have never used a step drill … I’ll bet it is just the ticket for thin stuff … brass or plastic where normal drills will cut an irregular hole unless you take special precautions.

Eric Schade said:

I have never used a step drill … I’ll bet it is just the ticket for thin stuff … brass or plastic where normal drills will cut an irregular hole unless you take special precautions.

If you ever do use one, you will be pleasantly pleased with how well they perform. I use mine for just about everything.

Step drills are great.

Would recommend not buying too cheap here.

Try finding double fluted ones they cut smoother holes.

Will bear all this in mind… Thanks guys.

Hi Jim:

My name is Karl, I’m a new member and this is my first post. I have some information related to your post and thought I would use this reply to introduce myself, comment on your post, and test my picture posting skills.

As an introduction, I’m a long time model railroader in various scales(around 50 years worth), and always a live steam enthusiast with a distinct fondness for G scale live steam. I am also, with my wife Jenn, the owners of a small manufacturing facility and have been a machinist for far to long.

I have to comment on your post about Center Drills. Although they can and are used for centering the start of a drilled hole, they are not designed nor best for that use.

They are designed to be used to create a taper and a lubrication pocket for dead centers on a lathe.The taper on a centerdrill is not correct for chamfering, countersinking, or thread starting. It is intended to match the angle of the taper on the dead center. The small drill tip leaves a pocket to be packed with grease, before bringing the tailstock with the dead center up against the stock to be turned between the chuck and the dead center.

These are also used for live centers, but because of the thrust bearing, no lube is required since the center turns with the material.

The proper way to start a drill is with a Spot Drill. These are beefy, short flute drills usually at 90 degree tip but available in other angles. They are designed to be rigid and not wander. They use a split point for further help staring on center. Normally, you use a spot drill that is larger than you drilled hole, and you drill deep enoungh to leave a chamfer after you drill. You drill larger than the diameter not only for the chamfer, but because the best way to get a drills split point to draw to center is to have the outer edges of the drill pull in first so the drill is near center when the split point hits. On screw machines with deep hole drill features in a part, you can find out quickly how far a drill can bend in a hole if you start with a spot smaller than the diameter of you drill. You will think the drill is working fine, and within a few thou of center at the beginning of the hole, only to find it is off by more than the drills diameter on the other side.

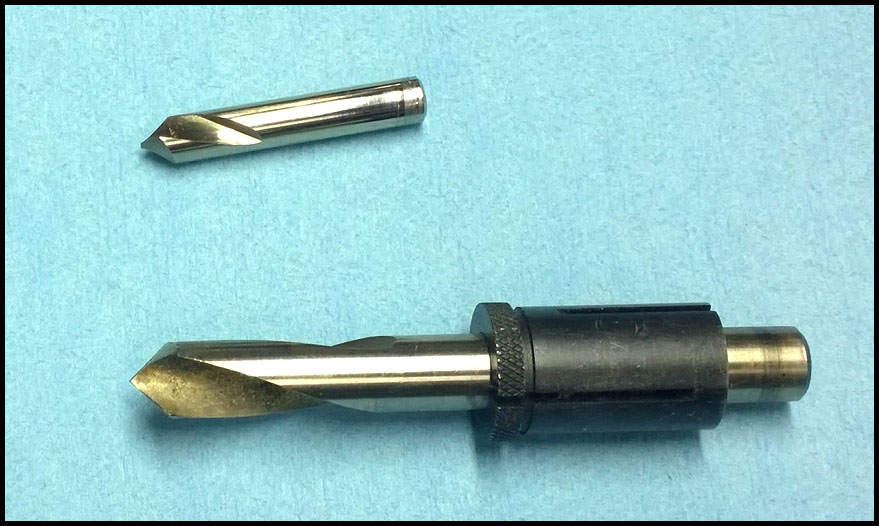

Here is my attempt at a picture of spot drills:

With two CNC lathes, two screw machines, and many years experience Supervising high volume industrial production machine shops, I have seen and heard it all. One of the

most common misconceptions is the topic of your helpful hint.

That being said, center drills will work to start regular drills for most needs of the hobbyist. Just thought you might find the clarification useful.

Thanks and happy drilling

Karl

You will think the drill is working fine, and within a few thou of center at the beginning of the hole, only to find it is off by more than the drills diameter on the other side.

Oh. Gee, and here I thought it was me doing something wrong. It was the drill bit itself flexing. I never would have guessed.

Even though this thread is about 5 years old, here are some Google results for spot drill vs center drill that may provide additional insight.

p.s. Welcome to the forum Karl.