Shiney.

Bruce Chandler said:

While Ray is doing fantastically detailed carving, I’m making el cheapo windows: hardware cloth framed with .100" angle and painted black. (With a few commercial castings thrown in.)

Bruce…I don’t understand the angle part…how did you do that? If I could do windows like that I could get over a big barrier I have toward getting my engine house started again.

Also, are you putting window “panes” in, on the outside or the inside of the wire, or both?

John, The angle piece is cut to length and glued to each side.

It sort of looks like this…

Ack…I tried to draw it with the keyboard…and that doesn’t work. Let me make a sketch…

Well, I’m not sure this is much better.

Eh? WHY does it rotate it? Anyway…ask away if this doesn’t help…

Oh yeah, one other BIG consideration. Hardware cloth comes rolled up. So, when you cut the windows you need to flatten them. I cut them to shape, manually straighten them, and then put a big weight on a stack of them.

You will also need to file down the edges where you cut the cloth. I typically use my Dremel tool to make it quicker. I use Black E-6000 adhesive to glue the angle to the hardware cloth.

Oh yeah, one other BIG consideration. Hardware cloth comes rolled up. So, when you cut the windows you need to flatten them. I cut them to shape, manually straighten them, and then put a big weight on a stack of them.

You will also need to file down the edges where you cut the cloth. I typically use my Dremel tool to make it quicker. I use Black E-6000 adhesive to glue the angle to the hardware cloth.

Then, these windows just go up against some clear plexiglass.

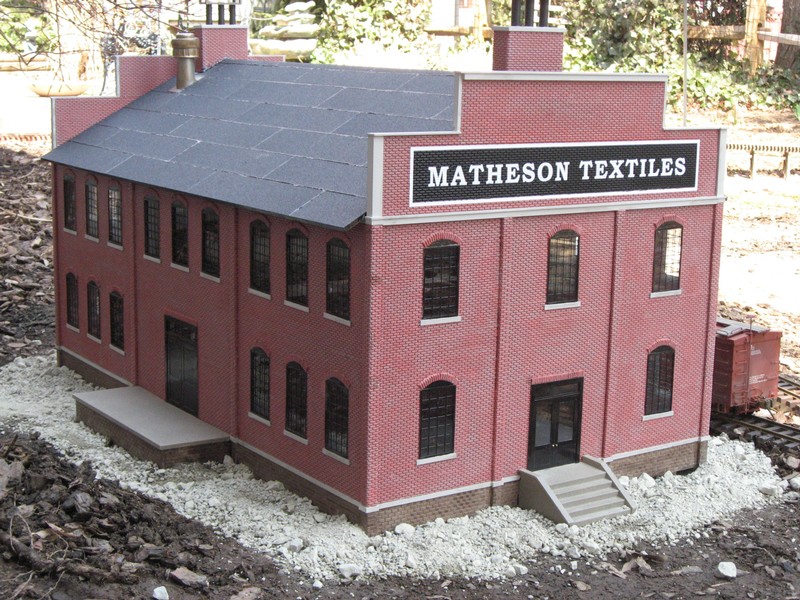

I have used this technique for several of my buildings…

Matheson Textiles is 42" x 24"…

Buchanan Tool & Die… a more modest 24" x 18"…

So, why didn’t I shoot this the right way to start? Sheesh…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-embarassed.gif)

Of course if you don’t understand it in the first place, this may not help.(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

John,

http://www.evergreenscalemodels.com/Shapes.htm#Angles

Edited because ZBruce chimed in.

This is a great idea. I use the plastic egg crate lighting to do much the same thing.

Mine are unnaturally thick. I have used my band saw to resaw them to make two windows out of each section. That requires a very fine tooth blade and a steady hand. The ones above are the full thickness and I don’t think they look bad. I do like Bruce’s better.

But both are cheap windows.

Bruce Chandler said:

So, why didn’t I shoot this the right way to start? Sheesh…(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-embarassed.gif)

Of course if you don’t understand it in the first place, this may not help.(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

I get it, and thank you very much, Bruce…of course my neck has been at a right angle for the last half-hour after looking at the first diagram!

Devon Sinsley said:

John,

I have used my band saw to resaw them to make two windows out of each section. That requires a very fine tooth blade and a steady hand.

I take it you have your six or seven Colt 45s after you cut?

Devon,

Get ye a fence for your band saw. Makes the steady hand an option! Trust me…

Got mine thru Highland Woodworking;

http://www.highlandwoodworking.com/kregprecisionbandsawfencekms7200.aspx

Mine’s an earlier inferior model… but still valuable!

John

John Passaro said:

Devon Sinsley said:

John,

I have used my band saw to resaw them to make two windows out of each section. That requires a very fine tooth blade and a steady hand.

I take it you have your six or seven Colt 45s after you cut?

The only way to get a steady hand is to have four or five colt 45’s

John Caughey said:

Devon,

Get ye a fence for your band saw. Makes the steady hand an option! Trust me…

Got mine thru Highland Woodworking;

http://www.highlandwoodworking.com/kregprecisionbandsawfencekms7200.aspx

Mine’s an earlier inferior model… but still valuable!

John

I do have a makeshift fence I use for this but it is still sketchy. Nice thing about a small band saw is it is a relatively tame beast.

A couple more details. First, I replaced the over-door light with a working unit.

I also dove into my parts box and dug up a bunch of gears and stuff. Need to degrease them, and rust them up, but this should make some good details around the building.

oh, are you a gear collector too?

Mister Bruce: Please, how did you paint the Red Bricks and not the mortar? I need to get your technique so I can build the Chama Oil House. Thank you. Paul Austin

Gee, that pile of gears, bushings and clutch disk, hub and spring look familler.

Huuummm…I don’t know that working light addition looks awful suspicious. Perhaps we might have a new Speakeasy in town? Is that a bathtub I see through the window or just a reflection ?

David Maynard said:

Gee, that pile of gears, bushings and clutch disk, hub and spring look familler.

They’re all from some giant double-motored, electrically clutched, geared drive thingy I bought years ago to strip out the stepper motors for some long-forgotten project.

As a copier repairman, I had boxes of that stuff. Just in case, you know.