In previous posts, I showed the building of a point to point 7-1/2 inch gauge track around my house. Those track panels are completed and ready to lay (this is a portable track and no different than a “G” layout using “snap-track”…although a “little” larger).

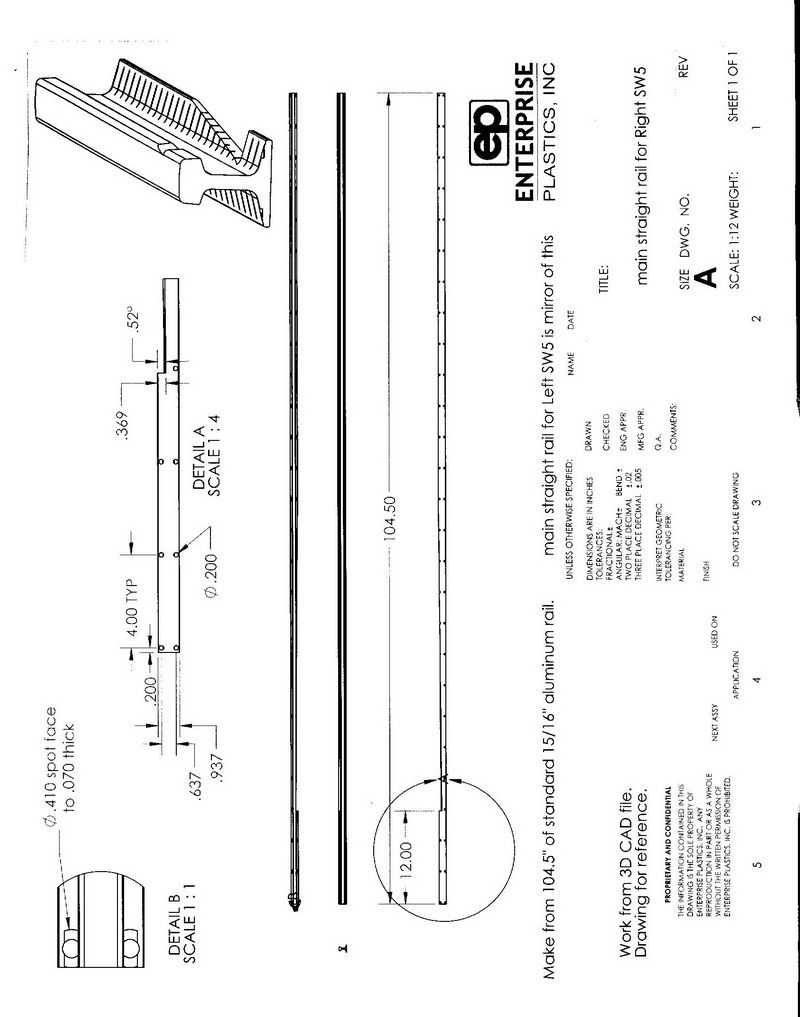

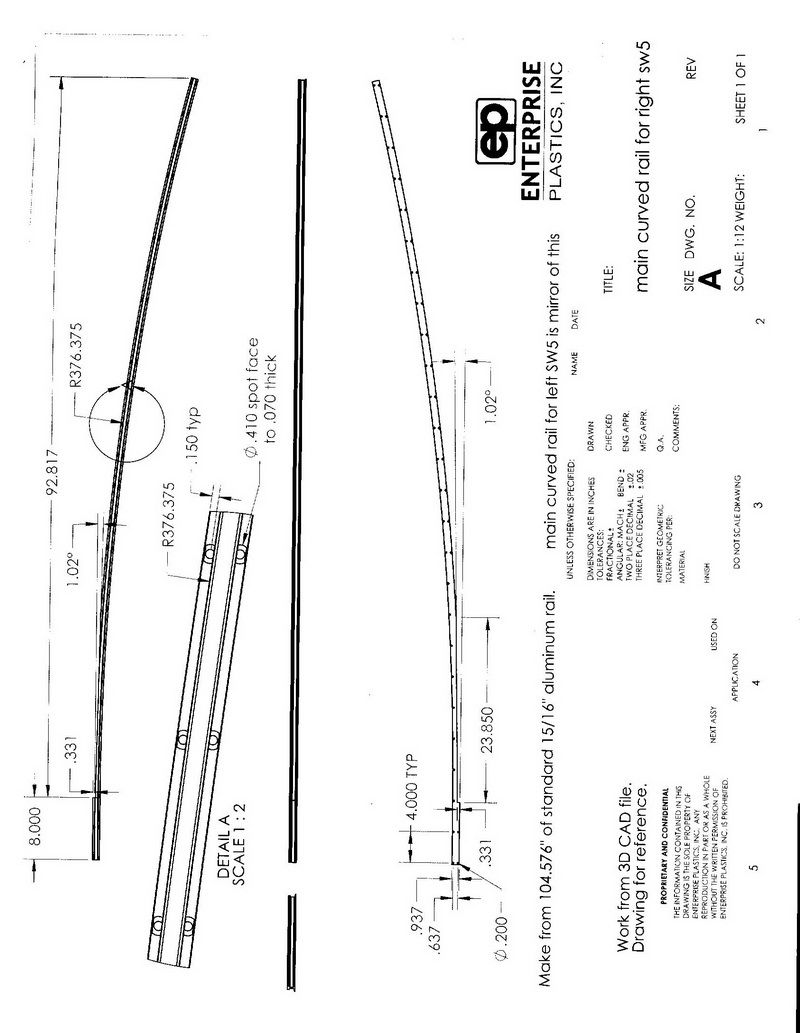

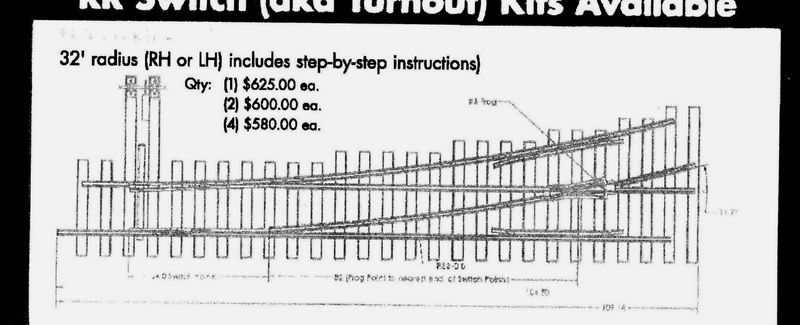

To help in the loading/unloading of engines and rolling stock onto the track, I have a “lifting rack”. This rack goes all the way down to “ground level”. I have contemplated either buying a RTR turnout in this gauge or getting parts from various vendors and building one. RTR is expensive…upwards of a thousand dollars each! Building from parts available is only for those with experience doing this because of the geometry needed to make this size work. But a company in Kent, Ohio (EP Plastics aka Accutie Rail System) has designed a system of plastic ties with molded tie plates with screw holes in place and the track is automatically “self-gauged”. These are the ties I used on the track panels. Recently they have added Turnout “Kits”. ALL items are included in the price: ties are pre-drilled by a CNC mill for the rail, frog and guard rails. ALL rail components are CNC drilled and numbered, steel points are CNC milled to the size turnout you want and predrilled to attach to the switch throw bar and to attach to the closure rails (BOTH straight and curved). The points come in #5 (32 ft. radius), #7 (62 ft. radius) or #9 (102 ft. radius). The frogs are exactly like the prototype and STRAIGHT through. The really nice thing about these turnouts is that the company will sell ALL or part of what you need. This really makes these turnouts well affordable. By the time I complete this switch, the cost is less than $225 including ties, frog and points, SS screws for mounting ties and all prints to build it. I will be doing the milling of the closure rails, straight stock rail and curved stock rail. I will be using individual plastic tie plates to establish gauge. AND I will be bending my own rail (code 1000 aluminum rail with a 15/16 wide base.

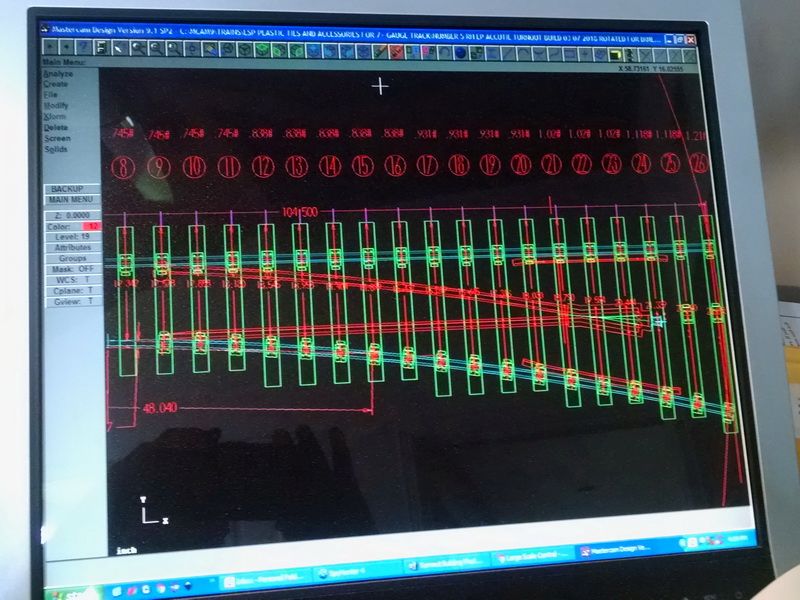

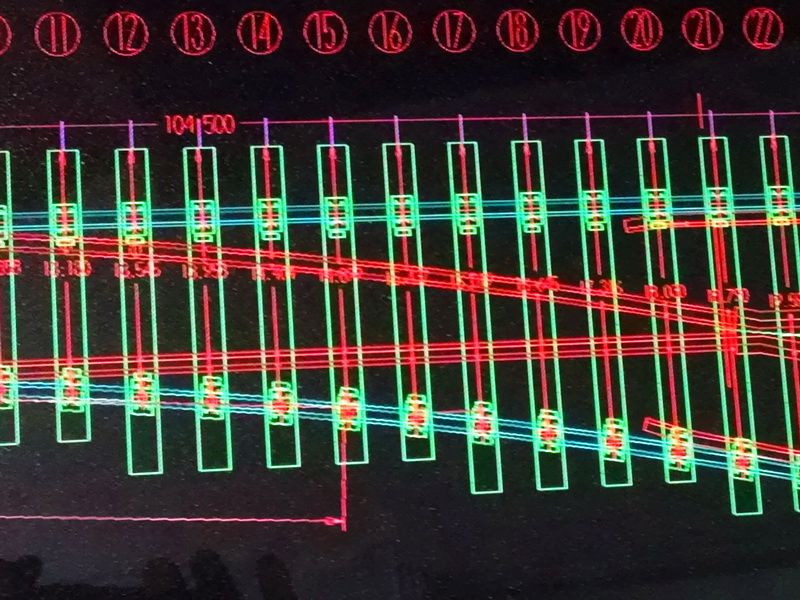

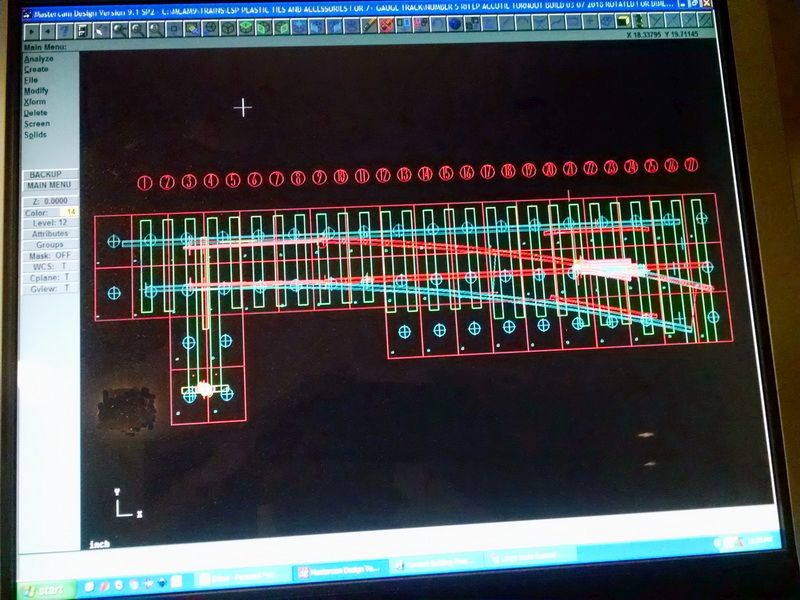

First I did a cad drawing of the switch with all components in place including ties, holes to be drilled in the ties, steel points using dimensions from their prints. This is a plus, because the geometry is figured out for you!

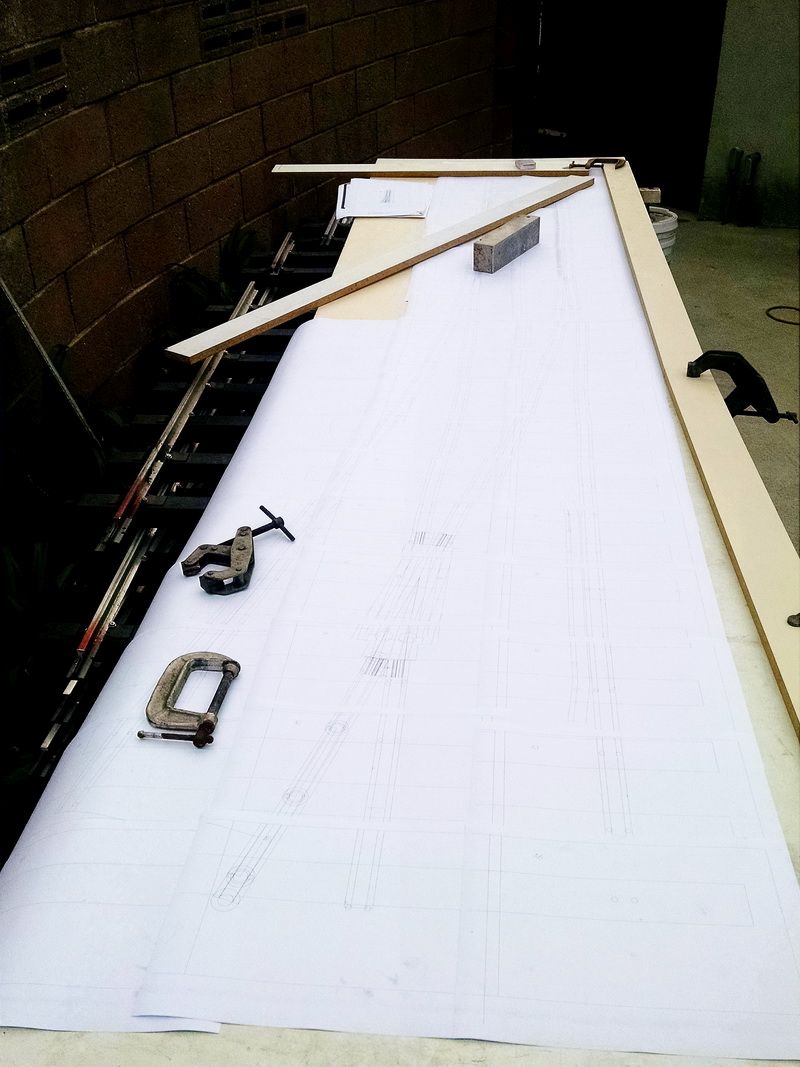

Because I have the full size cad drawing, I can now make a FULL size accurate plot (using PLOT in the software) and make an actual template to layout the turnout and fit pieces into place. In the photos below, this is what I have done. You can see the frog here in the foreground and possibly the points on the opposite end. Also shows the ties placement. BTW, the ties are on 4 inch centers.

I have a friend who just happens to live within four miles of the West Coast distributor for Accutie Rail Systems in Minden, Nevada (Allen Models of Nevada). So my shipping cost is ZERO. Another plus. My friend made a delivery here last Saturday and we laid out the ties, rail and switch stand to check for size of this large switch.

Forty feet of West Coast rail. The two outside rails will be the straight and curved stock rails. The two middle rails will be the material for the straight and curved closure rail.

The 2-1/2 square aluminum block is one of my two track gauges. 1/2 inch wide groves milled into the block that fits over the rail head. The 16 inch tall switch stand is on the right and will be mounted on the two 30 inch long plastic ties.

You can see the individual plastic ties plates set in place temporarily. The ties in the foreground are 2X2X16 inches long. UV protected. Many clubs in the US now use these…they last “almost” forever, impervious to rot, weather.

Another shot of the ties and tie plates.

Box of 250 plastic tie plates…dime a piece (very reasonable).

Four holes molded in to each plate. The base of the tie plate is “canted” inward toward the center of the track panel (per prototype) 1-1/2 degrees. As you can see, all that information is engraved on the plate. You can see the 15/16 web width and the arrow and note showing the “inside” of the rail. Almost “foolproof”.

Fully machined steel points. I will receive the points and frog in my next shipment. NOT in Nevada yet :(. But I have quite a bit of work to do in the meantime…cutting and bending rail. Then machining the notches in the stock rails for the ends of the points. Build continues…