Dan Hilyer said:

Well, Dan, no one would ever know that has been printed. Great job. Paint job looks awesome too. I’ve thought about an SLA printer for details that are just to small or intricate for the FDM printer but it looks quite messy. Any feedback on the complexity of the process and/or the durability of the prints would be welcomed.

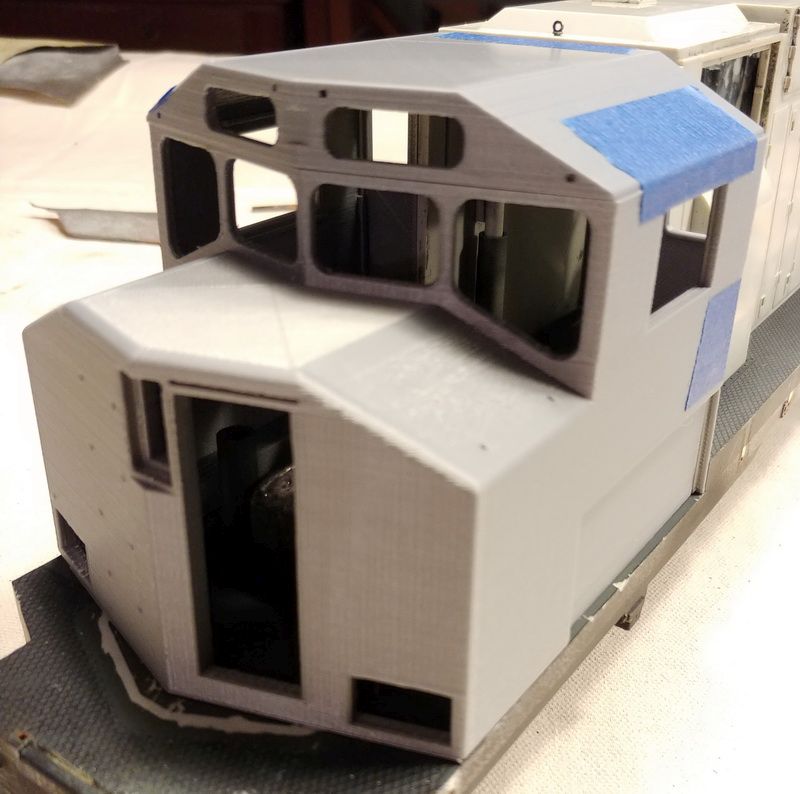

Thanks Dan. The paint is not good at all. I chose the most flattering pics. I got impatient and applied too thick of a coat of some old rattle can enamel (in the dark). No matter, this is the prototype I made for testing.

The process is a bit messy but not as bad as I expected. Probably because the parts I’m printing are so small. I’m usually able to remove the parts after printing with the included spatula into a pickle container filled with 99% alcohol without making contact with any of the nasty stuff. Then I just “squeegee” the build surface with the same spatula and I’m ready to print again. Post processing prints involves shaking the pickle container for a few mins then spilling the parts onto a paper towel. Some parts need a bit of work with some alcohol and a toothbrush. Let dry and place under UV light for a few mins.

First week observations:

Even at .05mm layer height this thing prints quite fast. Unlike FDM, It takes the same amount of time to print 20 of a part as it does to print one. Time to print all details 48m 21s

Resin is more expensive then filament but printing these small pieces is cheap. Total cost standard resin for all details $0.39.

Smell is not bad at all. Although I have only used Elegoo standard resin.

Much quieter than my FDM printers.