Aloha!

Clan Mueller, with the help of the boys’ 1:24 scale friends, is pleased to present ka Hale Ipukukui o Haluku’ilio (the Lighthouse of Dogwallow). Unfortunately, the new navigation feature drew some scallywags to the port, requiring the strong response of the 1st Haluku’ilio Volunteers to deter a landing:

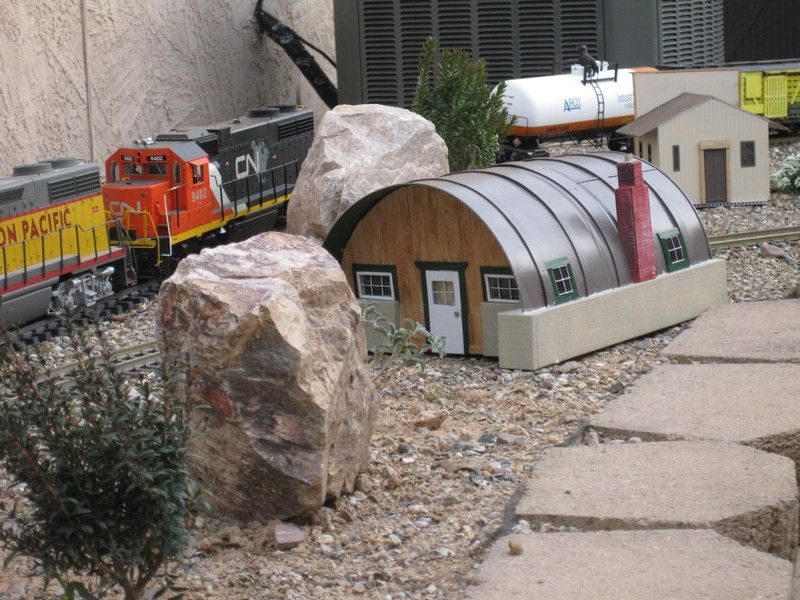

The far side of the photo may give a less dramatic but more informative picture of the final product:

Diesel Dan, who will be bound for the shops shortly for an overhaul himself, services a work train. Being lunch time, the crew has bugged out to Mama’s Bakery No Ka Oi where Haluku’ilio Police Department (HPD) members are arriving for lunch as well:

That has exactly nothing to do with this year’s build, but I thought the boys did a good job staging the shot, and it does help tie this year’s build to a previous Mik challenge!

The lighthouse looms nicely over the town. It gives a nice vertical element that should help add to the illusion that trains go somewhere:

O.D. and I had to spend about 90 minutes this morning reworking some of our “boulders” under and around the ambulance to make way for the new building. We both had been trying to a achieve a dry streambed look with that portion of the railroad, and this offered us an opportunity to improve that. We applied some of our aqua-scaping tricks to again add elements of depth by ensuring the rocks rose up towards the “Dudestep Range” (Hawaiian word lost to history…) that served to separate the port city of Haluku’ilio and the mil town of Pu’u’oma’ao visually and physically. Let no opportunity to improve the railroad go to waste!

And, of course, I almost forgot a nighttime video: Hale Ipukukui o Haluku’ilio

Before closing, I have to review concept, cost, execution, and details.

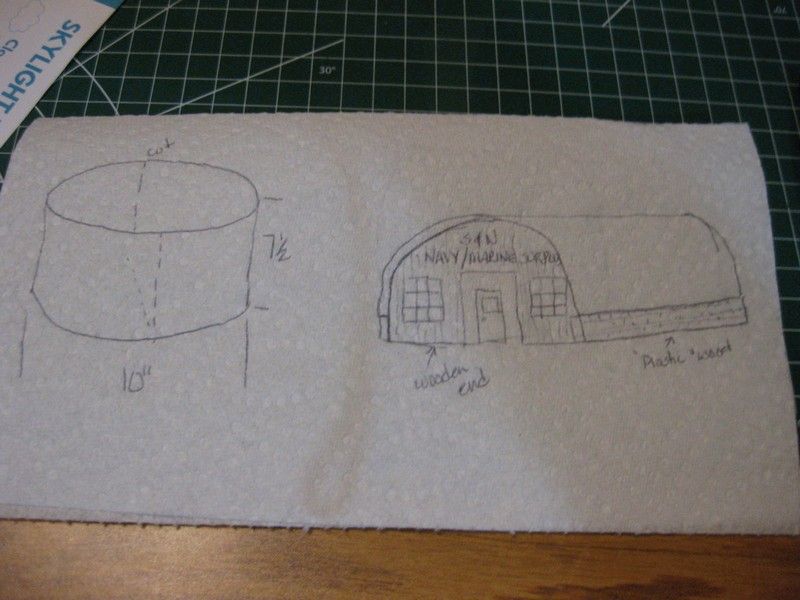

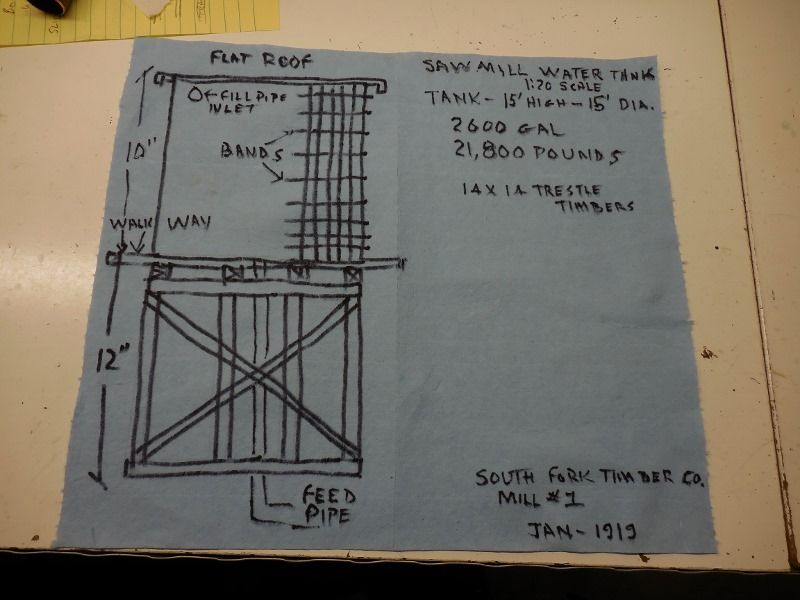

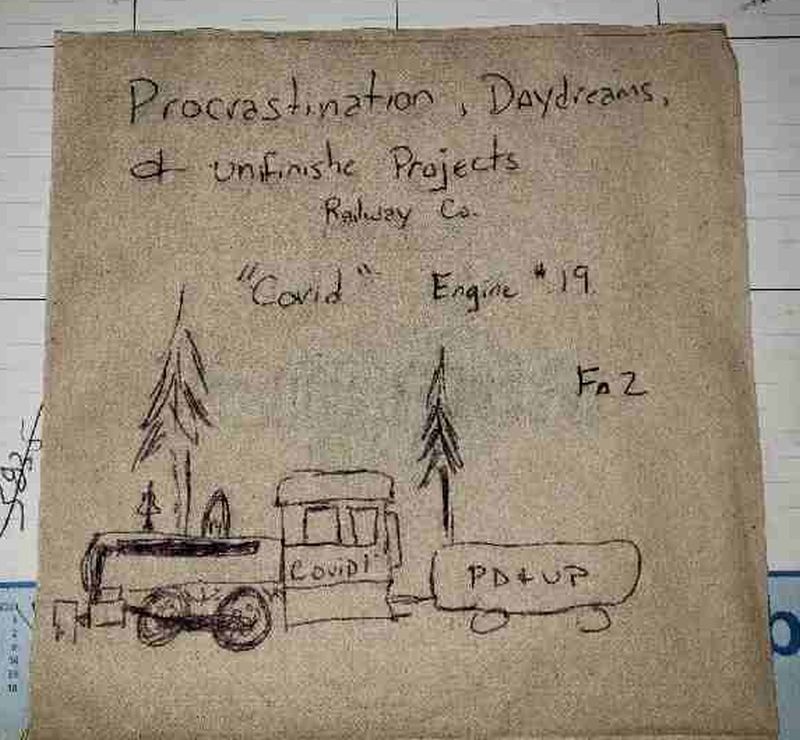

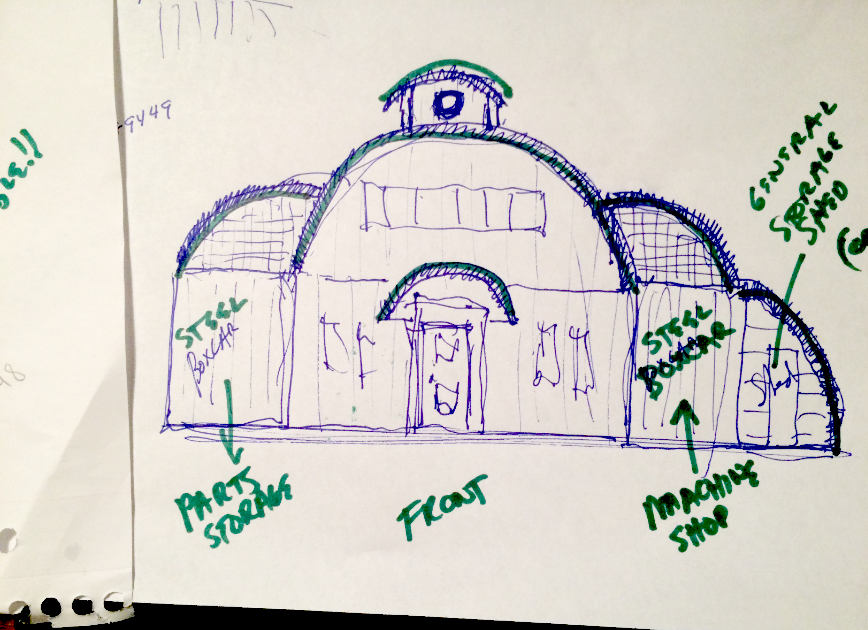

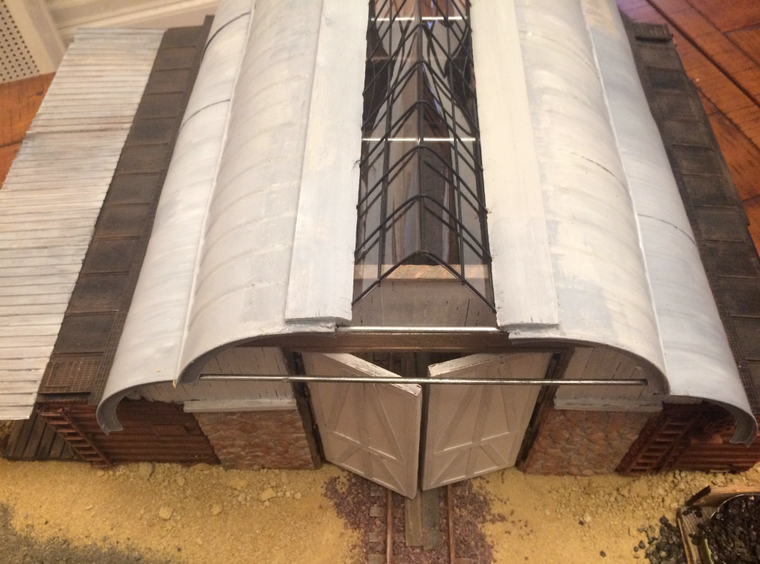

Concept, Cost, and Execution. “It cannot be just your (my) hobby!” served, as ever, as the guiding directive for the project. As such, The lighthouse combined elements from the crew’s four sketches:

The core of the lighthouse is various soup cans. We cut up foam trays for stones and painted it with white latex. I freehanded the blue stripe with acrylics. The base / keeper’s house is foam covered in concrete patch. Doors and windows are from scrap styrene. The wood is from our collection of scraps and craft sticks. The safety rail along the top is from cotter pins and jewelry chain. We had to purchase the lighthouse topper, a can of spray paint, some chain, and some cotter pins. The light itself is store bought but painted in accordance with design specs. The cost was probably about $25, with half of that being the light.

Details. I’ll highlight some key details below. I always try to move the crew towards greater independence and, at the same time, try a skill or work on one against the day I model solo.

Windows. The girls painted an interior on black plastic, which they affixed to my slipshod window frames. In all seriousness, I am OK with the frames and mullions as a first attempt at this. These are the photos I included in the build thread:

O.D. and I since touched up the paint around the frames.

Hibachi (Grill) & Door. The boys contributed these details.

O.S. did the door, largely on his how using scraps. Model building, he claims, is not his thing. I think he did OK. Kid-zilla decided the 1:24 crew deserved a hibachi. He selected some scraps and bottle caps and used Shoe Goo to hold it all together. Y.D. helped with the spray paint. He made the bench from scraps, too, using TiteBond III with a little help from yours truly.

The Roof Hatch. With everyone else stepping up to the scrap-to-detail plate, I felt compelled to do the same. I made a little roof access hatch from scraps. The pull loop is a jewelry link held in place by scrap aluminum from the mill project. I thought about hinges, but they would be out of sight.

The Light. This is a commercial product (Thanks Eric Schade for letting me know this exists!). I masked and spray painted the roof. O.D. drybrushed the bricks using acrylics and then a Sharpie to re-blacken the mortar seams:

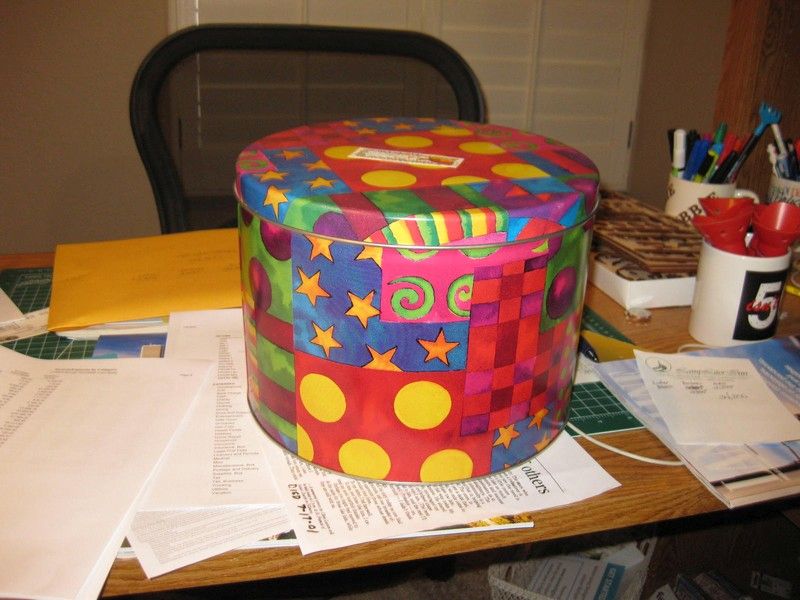

It sits on top of a cookie tin filled with foam. The foam gives a nice friction grip. The two shady characters to the right are about to discover there is no escaping HPD!

This project has been fun. I was wary of the flying buttresses, but they worked! I think we all improved our modeling and / or crafting skills, and we ended up with a finished product that strikes in that zone between toy and model. My thanks as ever to Dave Taylor for hosting this annual event! I look forward to see what evil lurks in the back corner of his mind for the 2022 Challenge!

On Behalf of Team Mueller,

Aloha!

Eric

Edited to add the video of the lighthouse at night.