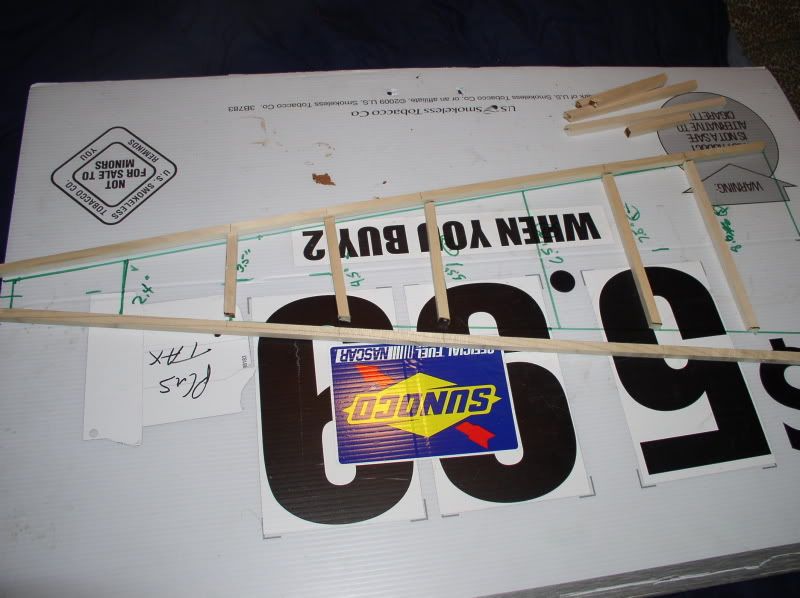

Well, I guess I get a DNF again this year. I kinda rushed a few things, but you just can’t rush wood glue… Framing for the beltway extension. On the model it’s just a big empty, but on a real rig not only would the ‘telegraph’ rope to the engine throttle, reverse reach rod, and sand reel lever run through it, but stuff like fishing tools, spare jars and coils of extra wire rope would be stored in there as well. Handy for when you need them, but otherwise out of the way. As usual, I’m allergic to making too many details nobody will see.

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120001.jpg)

Planking going on…

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120002.jpg)

Jumping around a bit, the side walls of the enginehouse went up…

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120004.jpg)

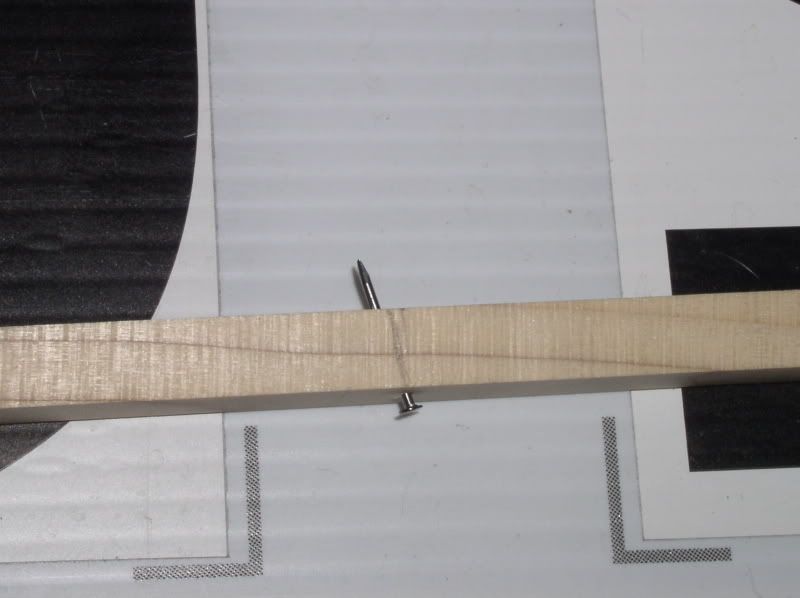

My usual cheater roof trusses.

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120005.jpg)

The bull wheel. A big thank you to Steve Widener for the hint I needed! I remembered this morning that I had a 3" pvc pipe couple in my scrapbox (to make traction engine wheels). The spokes are tongue depressor size craft sticks.

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120007.jpg)

mounted and braced. Now I just need to find the ball of surveyor’s string that I put somewhere so I wouldn’t lose it…

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120008.jpg)

The freezer is about 6" too short!

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120009.jpg)

Trying to visualize the layout of the boiler and enginehouse

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120010.jpg)

Sand reel is a spool and two wooden nickles. I really wanted to roof the beltway with corrugated sheet. But I never got around to buying a crimper, so ‘tarpaper’ it will be - once it stops snowing long enough to spray the aluminum furnace tape flat black (or maybe flat olive green)

(http://i1082.photobucket.com/albums/j371/AlleghenyValley/derrick/P2120013.jpg)

The derrick itself is probably 95% done now. The only major bits missing are the wire ropes, the walking beam stirrup and pitman, crank, and temper screw… Another day or two and maybe $5 worth of parts would have finished it. The enginehouse needs the siding on the end walls and roof. plus a bunch of details… And the beltway needs built. But first I really need to find a piece of decent plywood for a base (about 15" x 40"!)