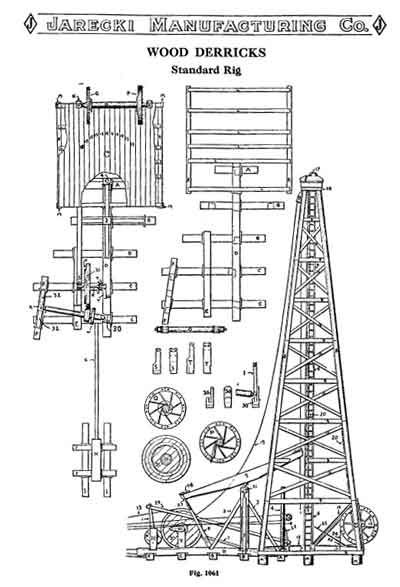

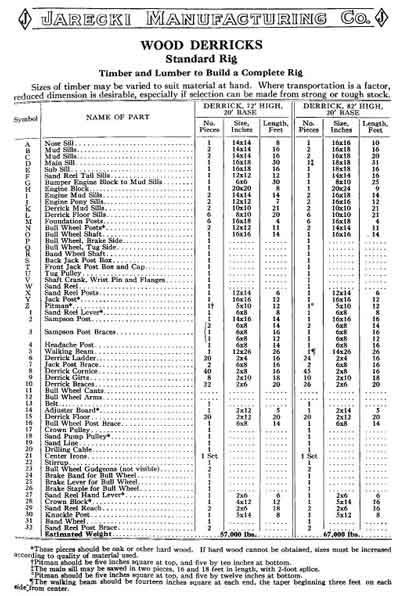

This one may take all winter, so be patient. I’ve wanted to do this project for several years – actually I WANT to do 3 of them eventually. The first one will be a pretty scale ‘operating’ foreground model version - to help figure out what corners I can cut on the other two which will be static. The oil heritage folks were nice enough to scan some Jerecki (Erie, Pa) standard rig info;

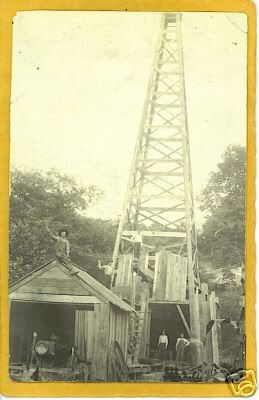

plus I’ve scrounged some old photos like these.

If I get stuck, I’ll take a ride up to the museum at Titusville. http://www.drakewell.org/ Right now there isn’t much to show. I have a largish pile of various sized lengths of wood. I have hand copied the Jarecki bill of materials onto a sheet of paper so I can scribble notes as I cut stuff (besides the scan is blurry when you blow it up!) One probable change from true scale will be square stock for the derrick legs rather than built up angle- simply for strength. I’ll also have to come up with a way to lay the derrick down for easier transport… More later…