About a week after reading Kevin Strong’s “40 Years” article on his Dad’s layout in the latest GR, I also read his dad’s “The Woodland Railway - 25 Years and Still Counting” article in 2005 GR. I’m slowly collecting and reading GR back issues, and this is one I recently obtained, so it was ironic to see these two articles back to back, and fascinating to see this famous layout over that time span.

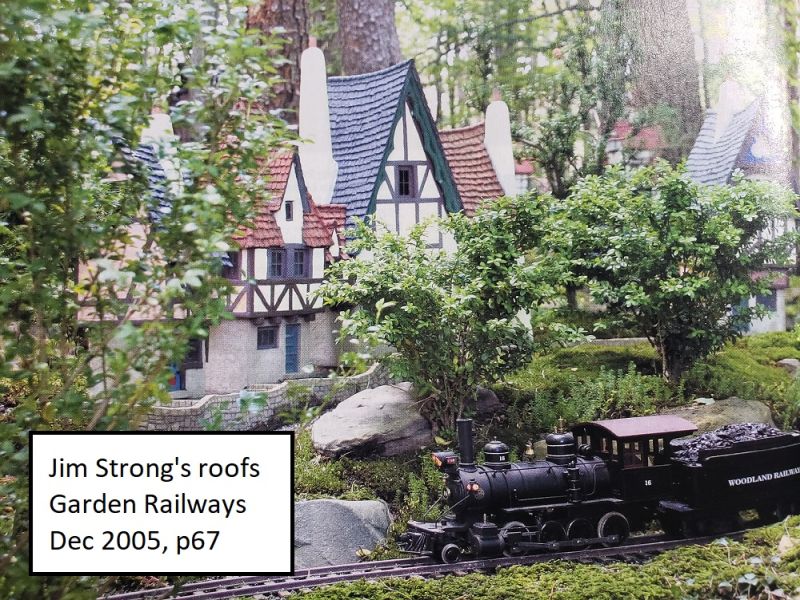

One thing that grabbed me in Jim Strong’s article was the statement: “All the buildings were constructed of vinyl concrete stuccoed over styrofoam bases.” This was in the caption of a photo that I’m posting a phone-pic portion of here:

Aren’t those roofs (I guess no one says “rooves” anymore) amazing?!?

I looked up the stuff, and found this version from Quickrete:

Per the manufacturer: “QUIKRETE® Vinyl Concrete Patcher (No. 1133) is a multi-purpose concrete repair material with strong adhesive properties. Trowels to a feather edge of 1/16” (1.6 mm). Made of a special blend of exterior grade vinyl resin, fine sand, and portland cement. Just add water."

This sounds like it will really stick to foam board or various kinds, especially since Jim said it stuck well to styrofoam. For sculpted roofs and walls, it looks waterproof and durable.

I’ve put the question to Kevin, and I’m sure he’ll respond; but I can’t keep myself from asking y’all as well: have you used this stuff? How well does it stick and last and hold a paint finish?

===:}Cliffy

Edit: Here’s an interesting comparison of thin concrete mixes like this that are good for “crafting” outdoors.

Nuther edit: Is this a viable (and much less expensive) alternative to the 2-part epoxy clays, like Magic Sculp?