Pete,

As promised, here is what we did. Note there is probably a correct way to do this; Oldest Son and I used the “look at it and guess method.” There are a number of screws on the bottom that look like they hold the cab on but do not. Here, Oldest Son removes what turned out to be screws holding in a cable channel (there is a channel on each side):

We were looking for broken or damaged wires, so removing those cable channels was necessary, anyway, in our case. Boy, was it a pain to get those wires packed back inside, though!

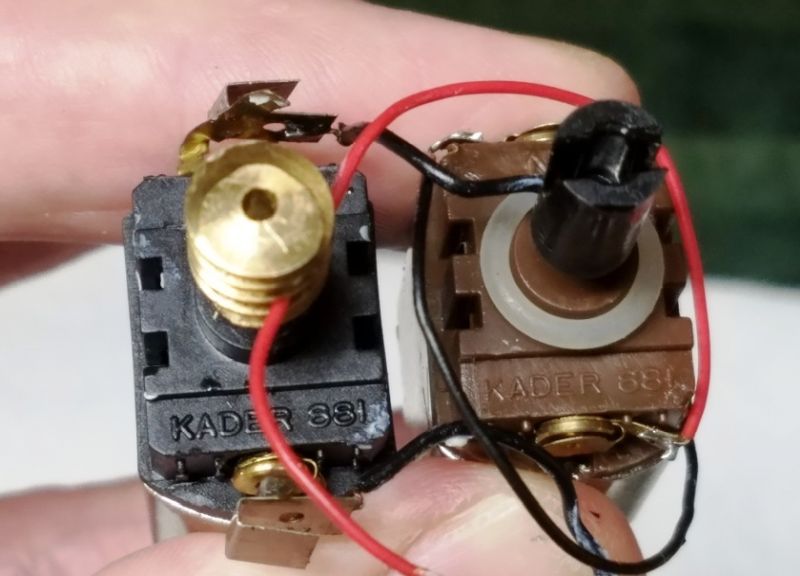

The screws actually relevant to the problem are all forward of the silver painted exhaust piping. From fore to aft, you need to take out screws that hold in the radiator grill (2), screws that hold the glide plate for those spring-loaded electrical buttons (4, I think) (We have a jumper wired from the wheel area to the plate. Those spring things were crap almost out of the box.), and a screw that holds the transmission cover in place. Most of these screws are visible in today’s picture below:

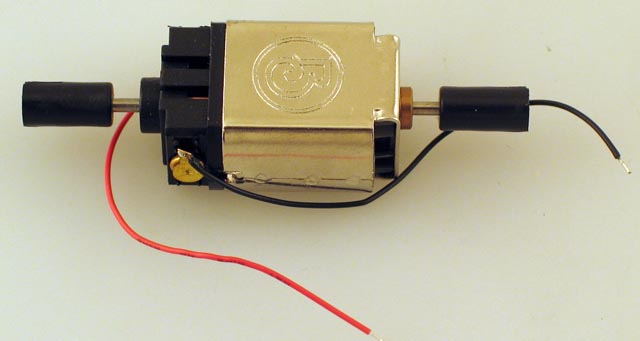

Once you have the “transmission” open, you can see the tabs that let you push off the plastic motor (Actually, a very nice touch in the detail department. Too bad it is wed to such rotten machinery…) , which, in turn, allows you to access the motor. I did not think it necessary to the do that tonigth, but the photo below gives you a sense of the size:

That resistor is the orang “booger looking thing” just forward of the grill. We did cut the wire as you suggested. Nope. This is a dead, dead motor. For comparison, here is the motor next to a salvaged B’mann 4-6-0 that ate its own gears (Beautiful model; bad engineering…I am seeing a trend. That loco got one of the new chassis and since runs great.).

The worm gear would engage the drive train, and we did kick around force fitting to the model. Oldest Son advised patience, which is unusual for him, so we will wait and see if B’mann carries the right motor again.

Oldest Son was pretty pleased with his efforts. Here you can see Charlie pretty much completely broken down last Saturday:

Again, there is no need to take off the box that holds the circuit board if you need to get at the motor. We took it all apart to inspect for broken, loose, or damaged wiring. There is not much slack, so getting the box screwed back on was painful, and now we do have an opportunity to re-solder a disconnected wire.

I have been very, very critical of B’mann in this post. To be fair, they handled this reasonably well when this model first showed problems shortly after purchase, sending Charlie back to us free of charge along with a new 2-4-2, since dubbed Smokey (As it turned out, the problem at that time was those stupid spring loaded contacts in the forward truck. An easy fix, had I known about it at the time. I found out about that after paying for it via an independent repair shop on the Mainland.). We did have to pay to ship Charlie to their repair site, in contrast with Piko which offered to reimburse us for a product if we failed to find a way to fix it locally via e-mail. I am just astounded that they would take the time to make such a detailed, fun model and then trust it to such a horrendous power train and electrical pick-up system. After this experience, I would rather pretend my STAINZ are Porters than take a chance on another B’mann model. Worse, it broke my boy’s heart when his train wouldn’t work, and I lost him to the hobby.

OK. I am venting. Excuse me. More plastic strips, scrap wire, and LEDs to convert to coach lamps as the Aloha State prepares to remain in lock-down through May. Glitchy Gustav still waits in the shadows, too… At least he worked for 2 decades before giving me fits.

Aloha,

Eric