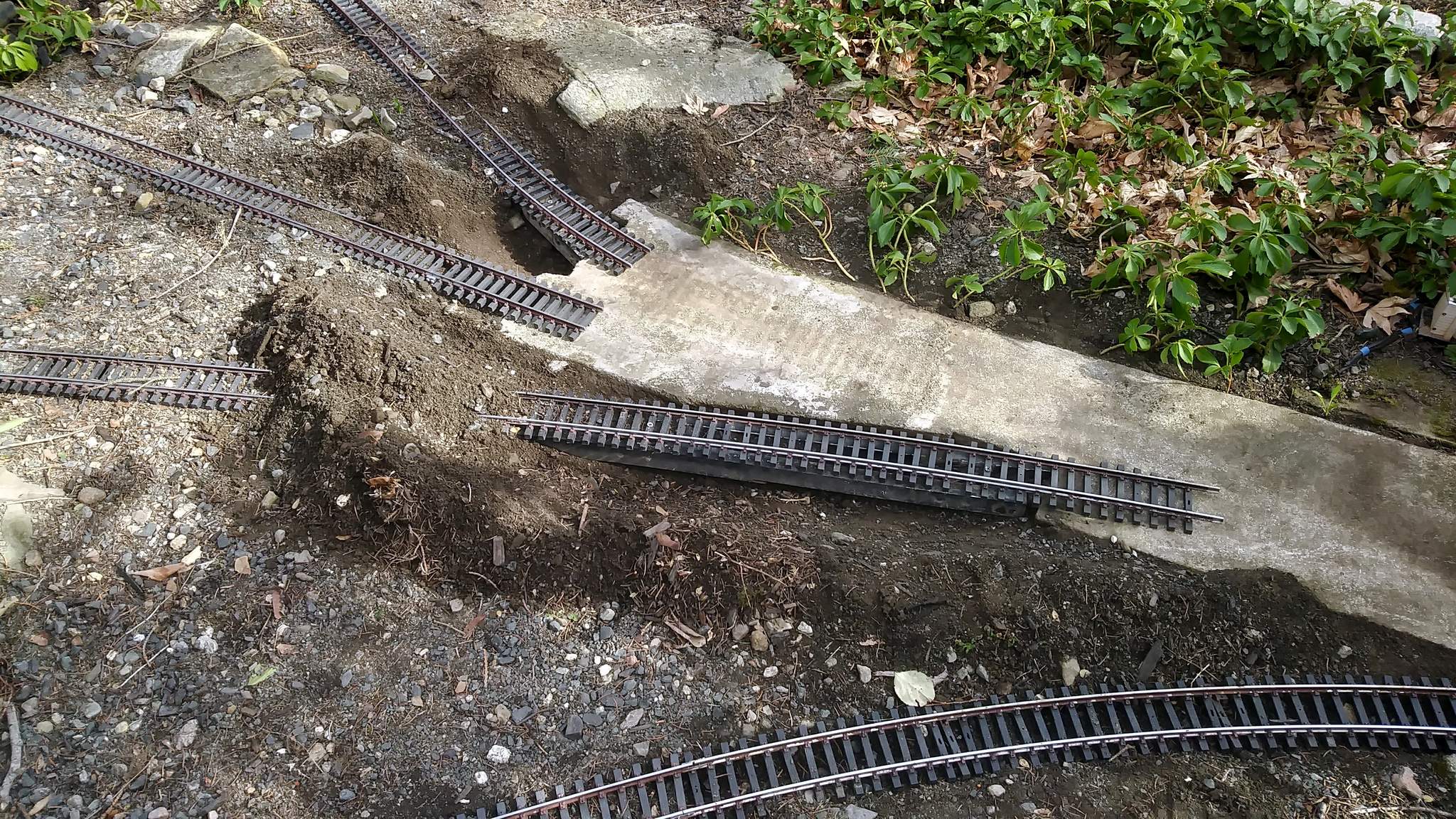

Traditionally, for me anyway, spring track work begins the weekend after ECLSTS. Since I didn’t make the trip to the show that wasn’t, and weather has been great, I got a jump on track work today. Last weekend I pulled up all 3 #6 switches at Indian Hill Junction for repair. With the switches out I noticed that either the concrete switch pad had sunk (doubtful) or the track on PVC roadbed had risen. In either case, the track needs to come back down to the level of the pad or the switches will have no support. After much digging, sweeping and hammering; all connections for switches are back even with the pad…

If I get cranking on finishing up the switch work tonight, maybe I can get a train past this point tomorrow.

In the mean time - Post up pictures of your spring track work for all to see