Well management has finally came to the conclusion that a snow plow is needed for the winter operations of the Shasta Pacific to continue. The past 3 years have seen record snow fall in the railroads operational area and something has to be done as the merchants and shippers that depend on the rail service are becoming nervous, and we won’t even talk about the mail contract.

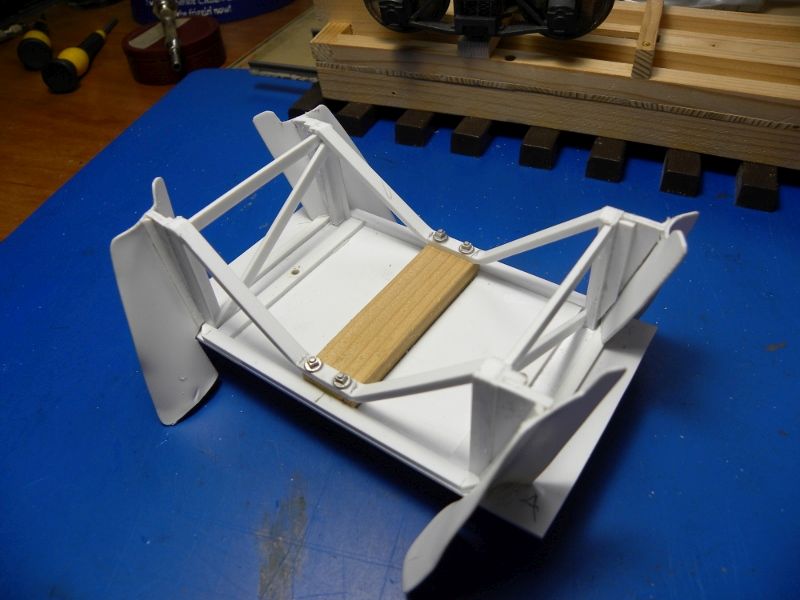

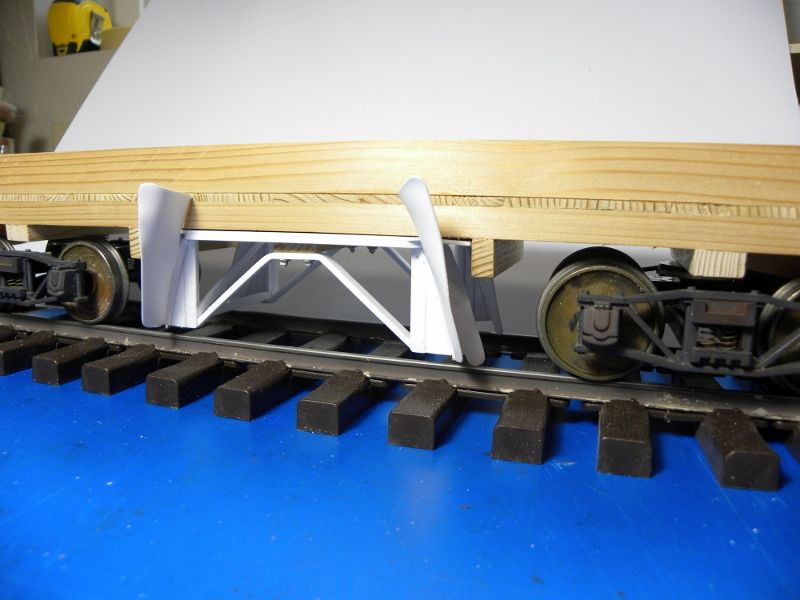

The company management went south and looked at a used rotary plow, after receiving the price quote and the general manager regaining consciousness the shop foreman assured him that a perfectly usable “Bucker Plow” could be built in the company shops over the Summer and be ready for service next winter. Not only that but a good Flanger could be put together using one of South Fork’s old Log Skeleton cars. He assured the General Manager that this combination would be more than capable of keeping the company’s trains running on schedule, well most of the time anyway.

Heavy wet snow and another scale 5 feet fell before nightfall, operations completely shut down.

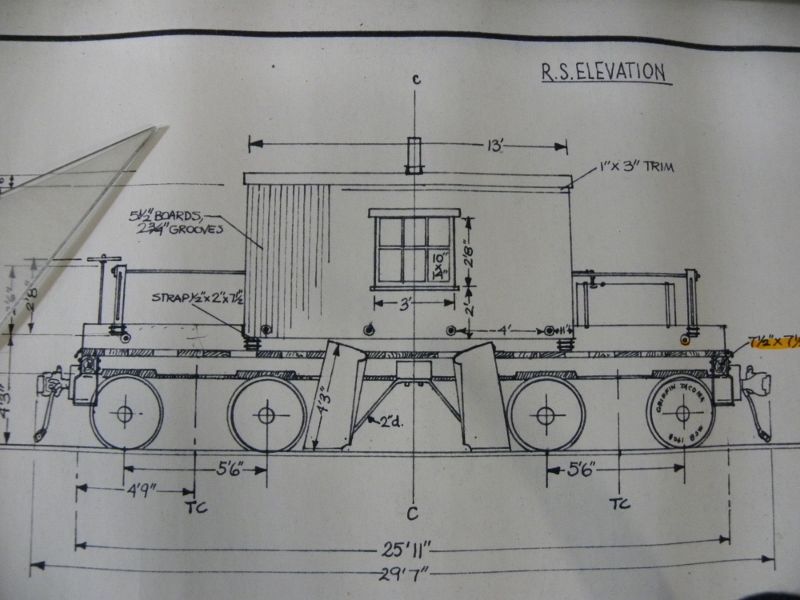

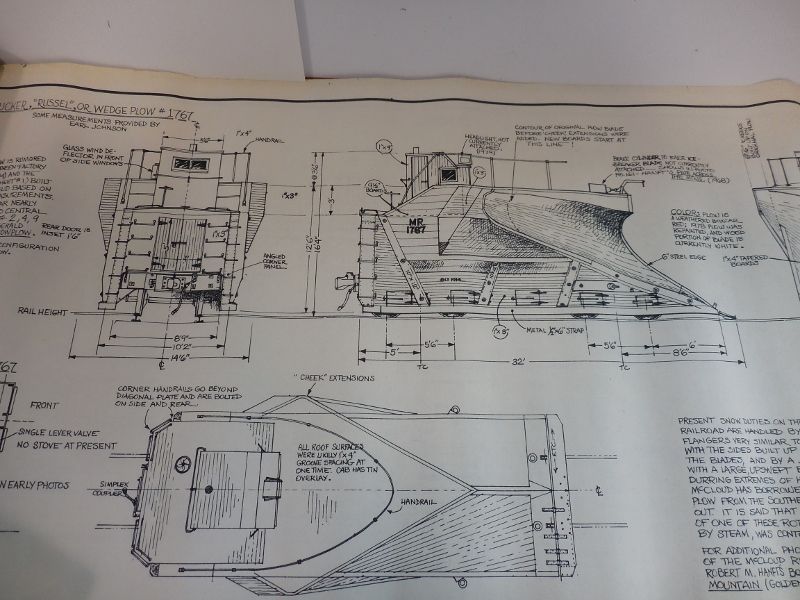

I have had these plans for one of the McCloud River Rail Roads “Bucker Plows” laying around for years and sort of at the bottom of the “some day” list.

I think this plow and a flanger are on the top of the list for this Summer. I think I will build a metal blade instead of the wood sheathed one in the drawings.

Early posting I guess (for a next Summer project) but it came to the top of the list today when all the snow slid off the covering patio roof and onto the mainline along the fence.

We ended up with almost 2 feet of snow along this section and had to shovel it off so it had a chance of melting off before June![]()

As was said in the early days of television “stay tuned”

Rick