Hopefully Stan Ames is listening because these questions are primarily for him. I thought I would make a public post so that others may benefit from the information I hope to gain.

From what I have been able to figure out by various methods, leaving the DC board in the socket and connecting your R/C using the Battery terminals provided will result in operation similar to using a trail car. In other words, headlights and effects will be present only when the locomotive is moving. Unless the 6V Input terminals provide power for lights and effects. If the Headlamp is powered from the 6V input; is it on only running forward?

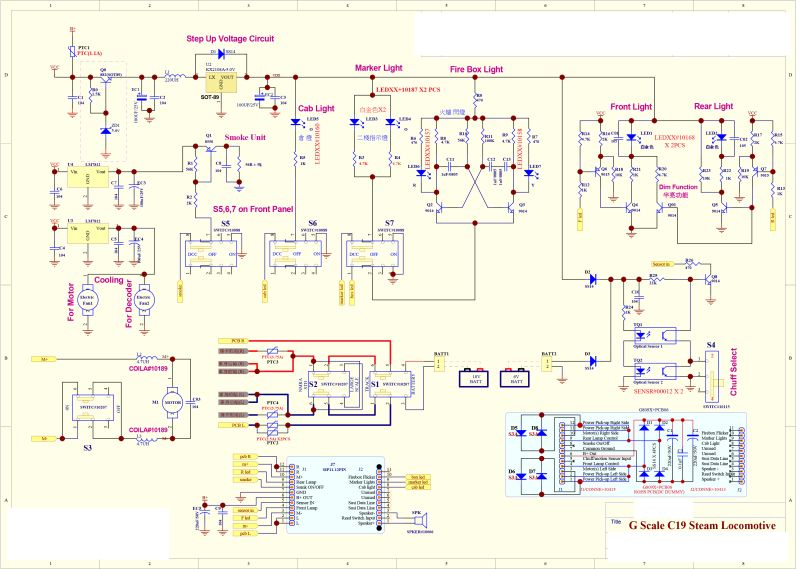

But I digress… Since I want complete control of lights and functions (like firebox & markers) I planned on removing the DC socket adapter board and using the pigtail adapter board to make my connections without soldering to the factory board. I did notice that when feeding the locomotive via the socket, the NMRA/LS and TRACK/BATTERY switches do nothing. So far I have success getting the loco to move and partial success with the headlamp.

I am using an older model RailBoss Plus (later called Hobby) board and I may add Del’s trigger board for more functions. For motor control I am feeding J1-3 (Motor -) and J1-10 (Motor +) from the RailBoss Motor Out terminals. This successfully controls locomotive movement in both directions and, as expected, the loco moves with no lights or effects on.

My next task is to get the headlamp functioning as it is used as feedback for programming the RailBoss. The RailBoss includes an LED driver circuit which provides a positive voltage current source and switches the ground for on/off control. Optionally, a positive battery voltage is available for use with lamps. I was encouraged when I saw in the socket pin assignments that the headlight connections were ground. So, as a test I connected J1-4 (Front Headlight Ground) to the Front LED ground connection on the Railboss. In order to function, the headlamp must get its current from somewhere. Assuming that J1-6 (Decoder Positive Output) would be that place, I connected it to the RailBoss LED current source. That alone didn’t light the headlight, so I connected J1-7 (Decoder Ground) to a ground output on the Railboss. With these 3 connections I got the headlight to light, but it is only bright when first switched on, then immediately goes dim.

So, folks who know, what is the proper way to feed the headlight? If there is already an LED drive somewhere in the locomotive circuitry, Should I feed it with the Railboss lamp circuit rater than the LED driver?

Where does the Headlamp (and other functions) get their positive voltage from?

What is the Train Buss (J2-4 and J2-5) for? I tried J2-4 as the plus voltage source, but no headlight at all. I did not try with J2-5 grounded.