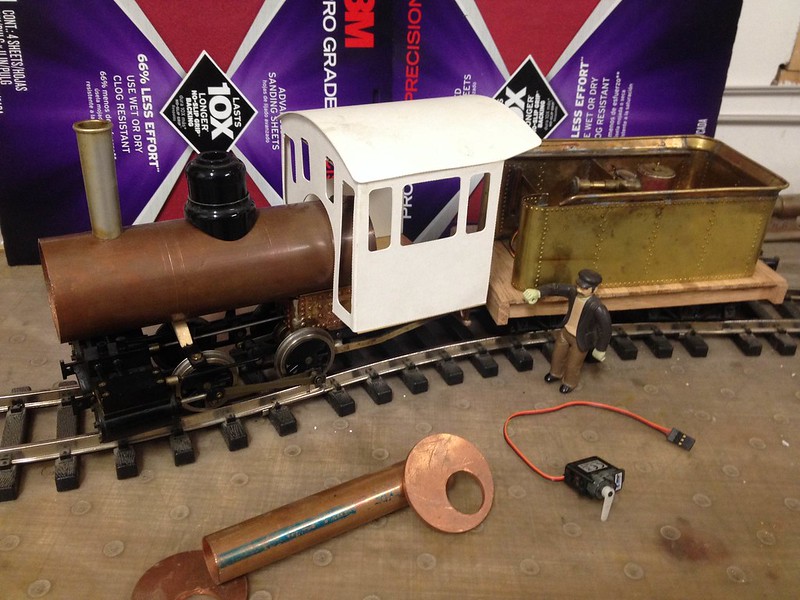

Hi All, I’m going to start with a teaser and give a bit of closure for the helpful folks that posed in my silver soldering thread. I’ll add another post tomorrow detailing the history and current status of the project.

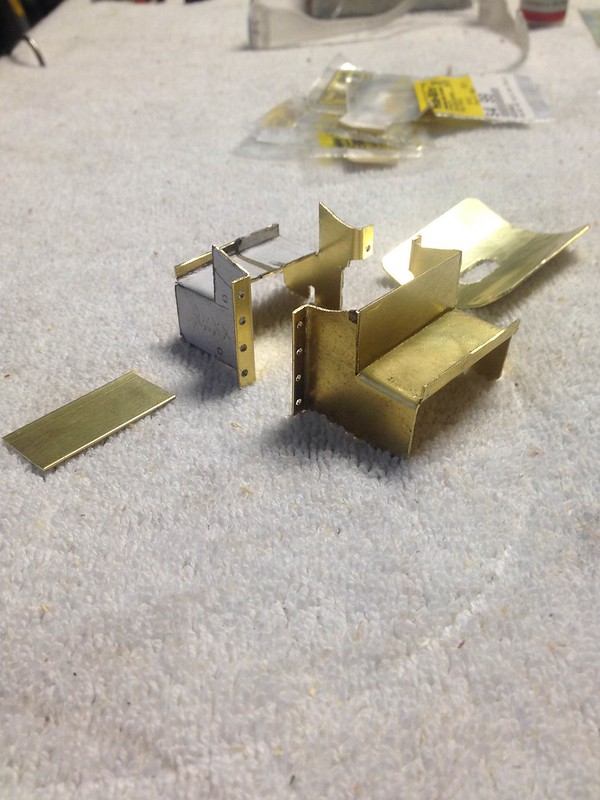

So, this first picture shows the new floor with it’s ribs soldered in place. The steel rod had some fire brick on it to hold things in place when you add the heat. I still had one that moved a bit. I had to poke it back with a scribe.

This next shot shows the mid frame parts that I bolted ans soldered.

In this photo I’m using a water bath to keep the finished back end cool while I add the strips to the front.

Finally every thing is soldered down to the floor, Slow and steady. I did only 2 of the 8 solders at at time. each of the 2 would be in opposite corners. I’d have a small bit of solder lying at the joint while heating and as soon as it melted and sucked it Id pull the torch away.

And the back view

Hope you enjoy, I’ll get “the rest of the story” up tomorrow.