Ah, that’s why I run the higher voltage and move the brush down, it will throw stuff quite a ways down the track, although parallel tracks need a couple of passes.

The higher speed, and lower brush position gives this velocity. Also, the simple fact that the stuff moved never goes perfectly straight, throw it further and you have a better chance of getting it off the tracks.

After actually experimenting and observing, I’m pretty sure that’s why it works so well. It will move big pieces of ballast, I use stuff that is just about the diameter of the tie spacing!

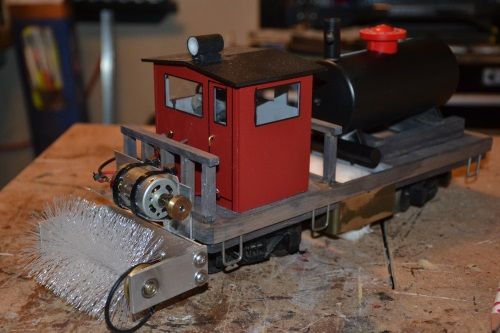

Do you have the model pictured? The manufacturer calls it the “rail broom” but there were a few clones made too…

Greg