Step 1 Grab oils after they have sat around for a while. Compare with other photo.

Step 2 of oil filter (after doing letter scraping,etc)

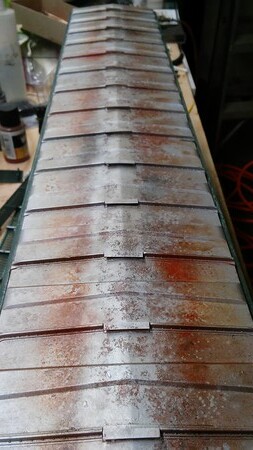

Place random dots all around the car body. I probably did more than I need, but I’m still learning. The more lighter colors the lighter of a fade, more darker colors the darker fade. I was trying for a dirty/light fade.

Step 3

Break out the biggest brush you have, and get it damp with mineral spirits (I use odorless, a bit pricer, but I don’t have to smell the dang stuff), and start brushing the entire model. It’s going to look like a mess.

Step 4

This is the hardest part. After spreading the paints around, clean the brush. Then slowly streak and clean off the oil filter weathering. Rise your brush repeatedly. It will look something like this. Let it dry, and let it dry. I normally wait 24 hours before I touch it again. If it doesn’t look good, you can go back and wipe the oil paints off with more mineral spirits. Or you can do a second wash.

I will see what it looks like tomorrow. It will probably need another layer. If I was good at this, I probably could do it once. While I was waiting for this to dry, I painted some burnt umber on the trucks, wheels (after installing roller bearings!), and on the boxcar floor. Next up, oil filter wash for the two ends. Then figure out what to do next. Probably start adding some rust scratches and dents.