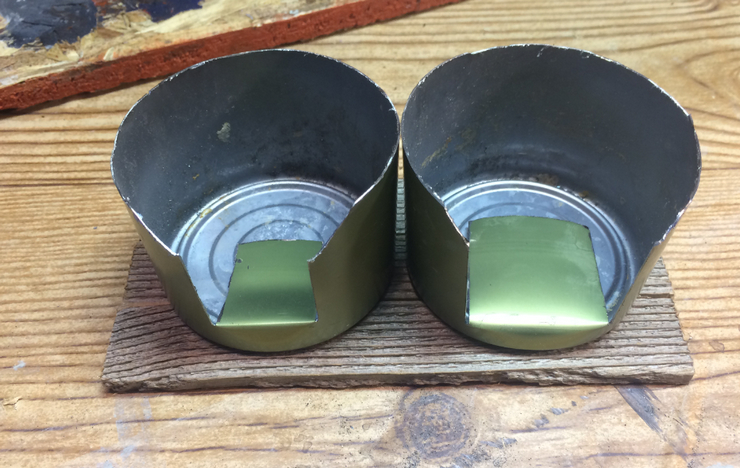

This has been the most challenging Challenge I’ve participated in. It’s the most time consuming for sure. I’m used to working kitbashing stuff, making things out of wood and foam, some plastic, but this is the first time I’ve tried anything involving metal, cutting metal, soldering, etc. The good news for me of course is that I’m expanding my modelling options…that’s IF, a big IF, it all fits together!

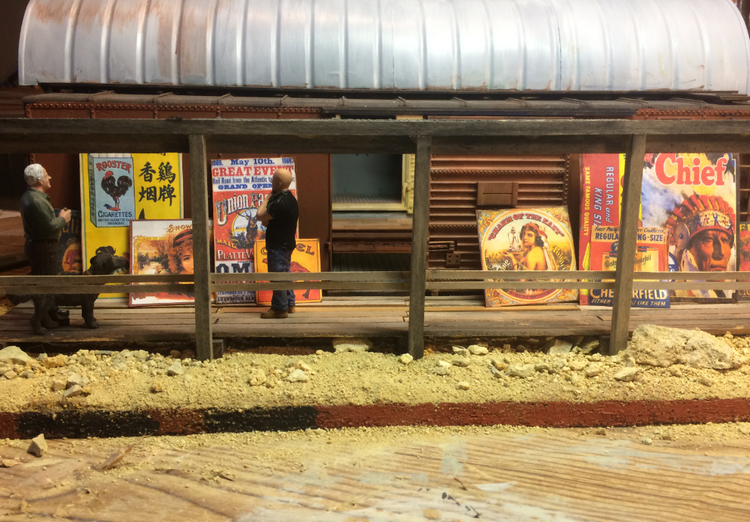

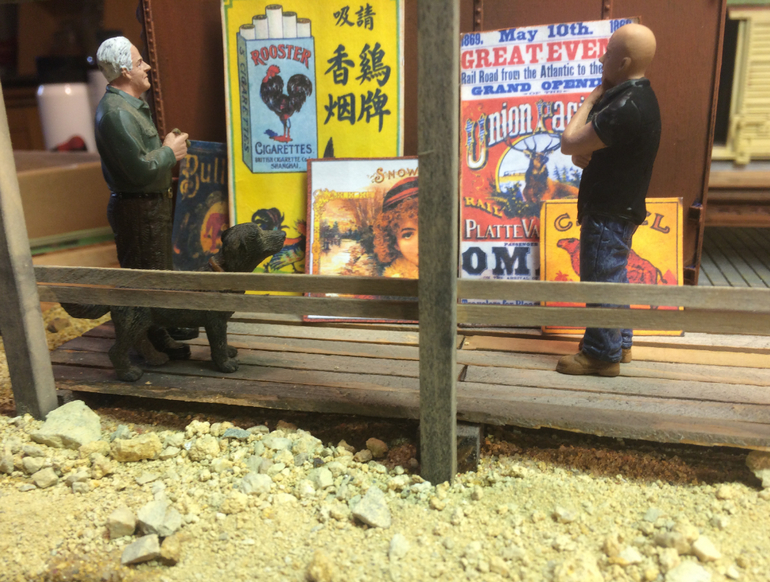

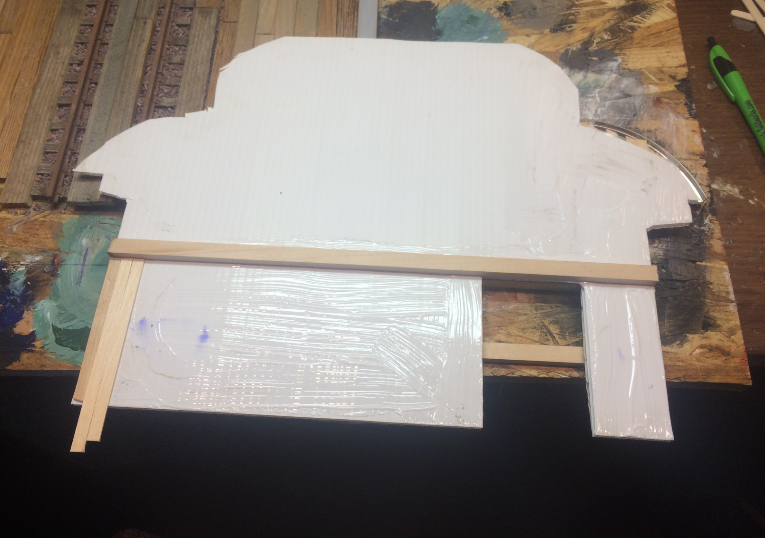

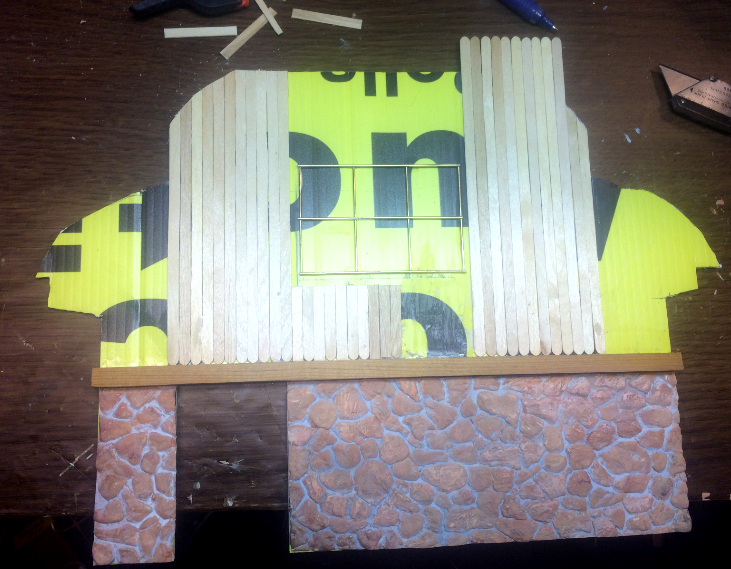

The place needed a floor, weathered track and ballast (I’m going with ballast in the repair shop because when it gets all oily and messed up I can have the boys replace it with fresh ballast), and I’ve been working on the back wall, surfacing the political signs inside and out. I’m using the H-shaped supports that come with the political signs as the supports for the roof. I like the idea of making use of the whole sign, very satisfying somehow, like Indians using the whole buffalo (okay, maybe that’s exaggerating a bit).

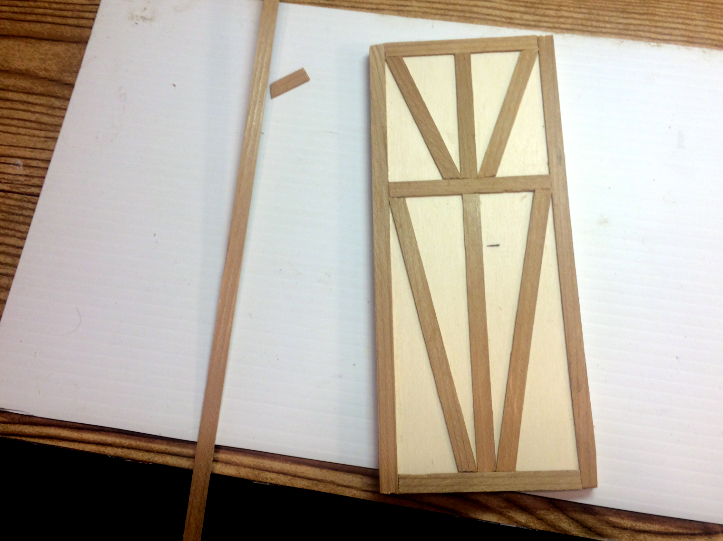

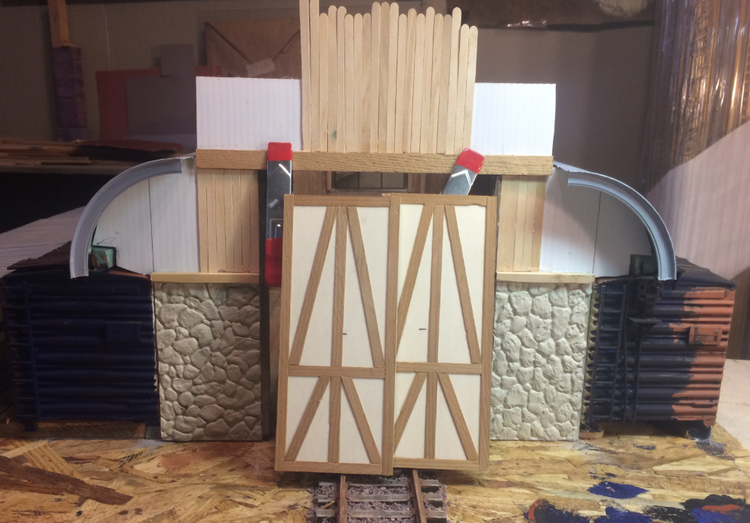

Here’s a few pictures of the back wall, but not to worry, I won’t bore everyone to death for the hundreth time about how I paint “stone” and weather wood.

Finally, at the Dollar Store (aka Covid-19 store) I found some wire metal in-boxes, in-baskets, I don’t know how else to describe them, but I’m cutting them up…whoever invented the Dremel tool is a genius…and I haven’t wrecked mine yet like that Pete Lassen guy (!!), although I feel that Pete and I are kindred modellers this year, using many of the same materials and dealing with some of the same issues. I’m cutting them up to make the glass top of the structure (not as fancy as the Paris train station!) and the big picture window high up on the back wall. That’s been my only out-of-pocket expense so far, like five bucks plus tax.

I killed off the green on the outside and painted it a light grey with some warmth and I’ll see how I do the finish weathering. I’m not happy at all with the color of the steel-sided boxcars. The interior colors look okay to me, but the blue doesn’t seem right on the outside so maybe the red.

The last picture is the side that will have the shed.

That’s it for now. It’s back in the ring this afternoon for another round, like Joe Louis ha ha ha.

Thanks for looking, and, please fellas, if you see something that doesn’t look right, let me know straight up, no kidding around.