Hello my North American friends,

I had disappeared from this forum for a while, but I am hoping to post more and keep involved.

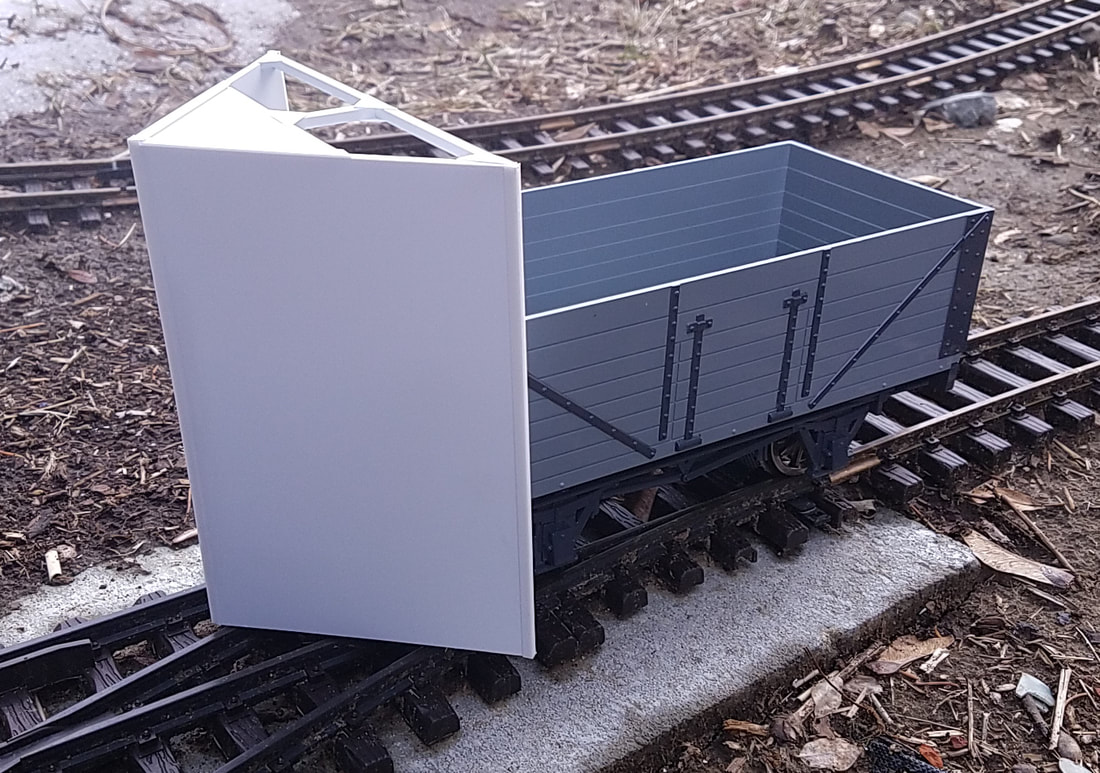

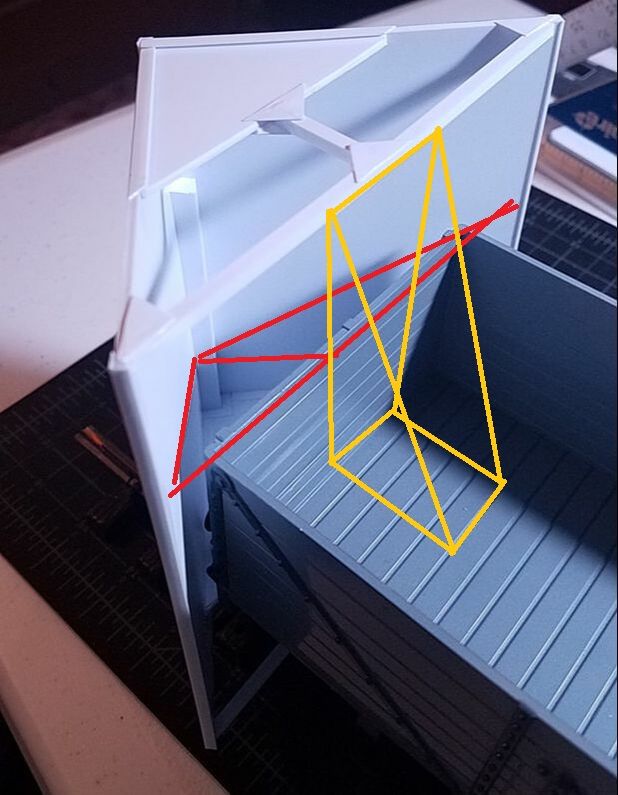

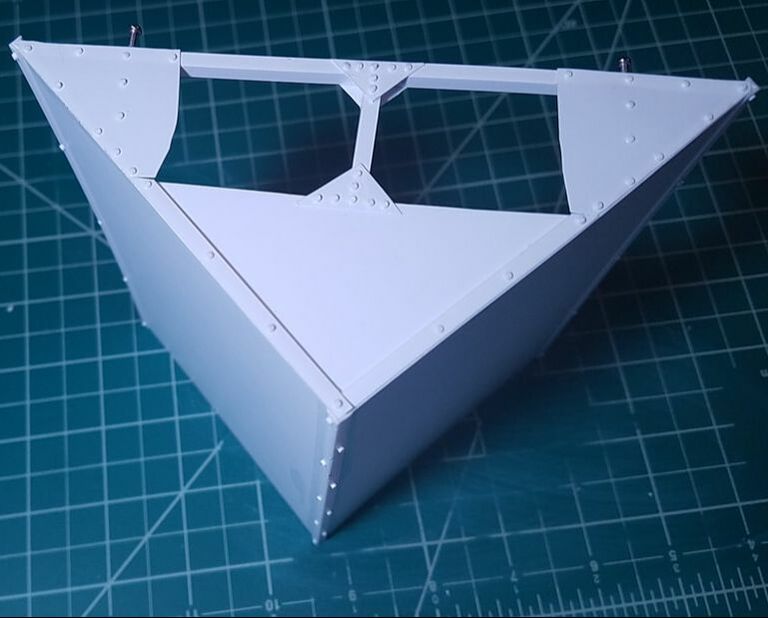

Yesterday I built a snowplow to attach to a Bachmann TTTE car. At the moment the plow is only attached by the screw holes meant for the front coupler. I’m thinking it needs some more support either against the front of the car or supports mounted inside the car. What do you think?

Also, this snowplow will end up with a headlight and battery pack in the car which will be hidden by either a coal or ballast load. The car itself will get decals for the LHRR and the plow will be painted either black or grey when it is done.

Ultimately I am very happy with this build so far, as it’s my first time building something larger than a scale pallet in styrene.