Hello,

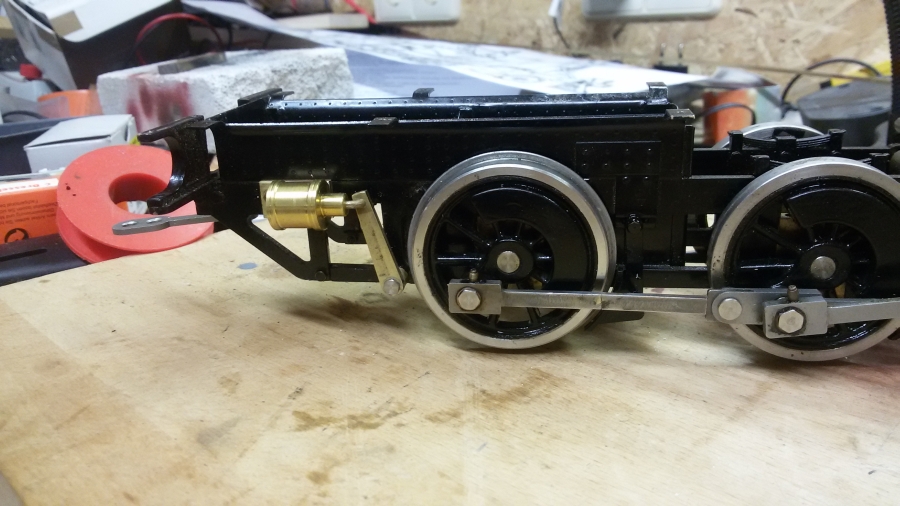

as promised above, here’s the latest progress on the tender body. I sandblasted the tender shell to remove all the paint. This makes any soldering action easier and allows some changes to the tender design. The paint was very sticky and it took me some while to get it off. Parallel to the sandblasting, I painted the tender frame, and let the paint rest to dry.

(https://waldbahner.de/wp-content/uploads/2019/01/IMG_20190105_203439.jpg)

On the tender, I relocated the rear hand rails from the side, into the bend, just as on the front end. First I soldered new rails in place, afterwards, I snipped the old ones off and filed them flush with the tender shell. Before that, I un-soldered the tender brackets, which will get relocated as well, while my tender frame is narrower then the original one.

(https://waldbahner.de/wp-content/uploads/2019/01/IMG_20190105_210054.jpg)

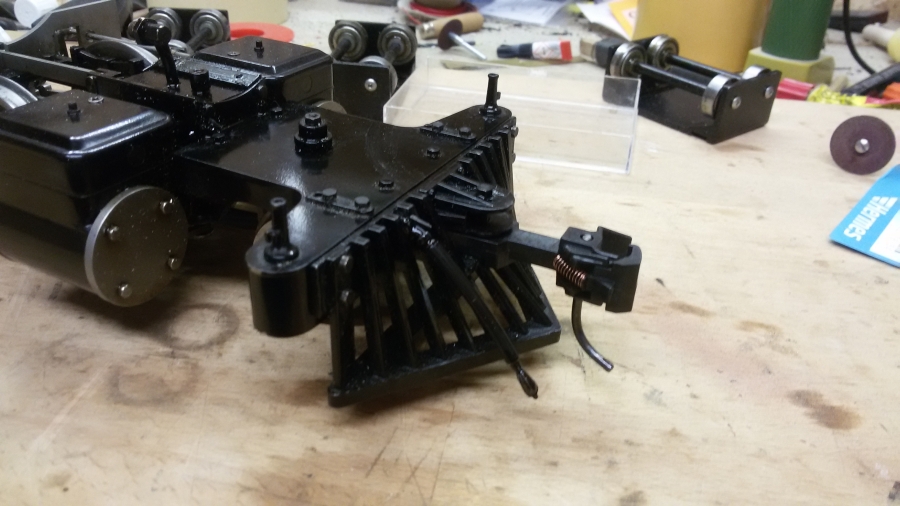

Another task was to fill in the holes in the tender shell. I mad small plugs on the lathe and soldered them into the holes.

(https://waldbahner.de/wp-content/uploads/2019/01/IMG_20190105_212104.jpg)

Then I sanded them flush with the tender shell on both sides. Once these are sandblasted and painted again, they wont be visible.

(https://waldbahner.de/wp-content/uploads/2019/01/IMG_20190105_212834.jpg)

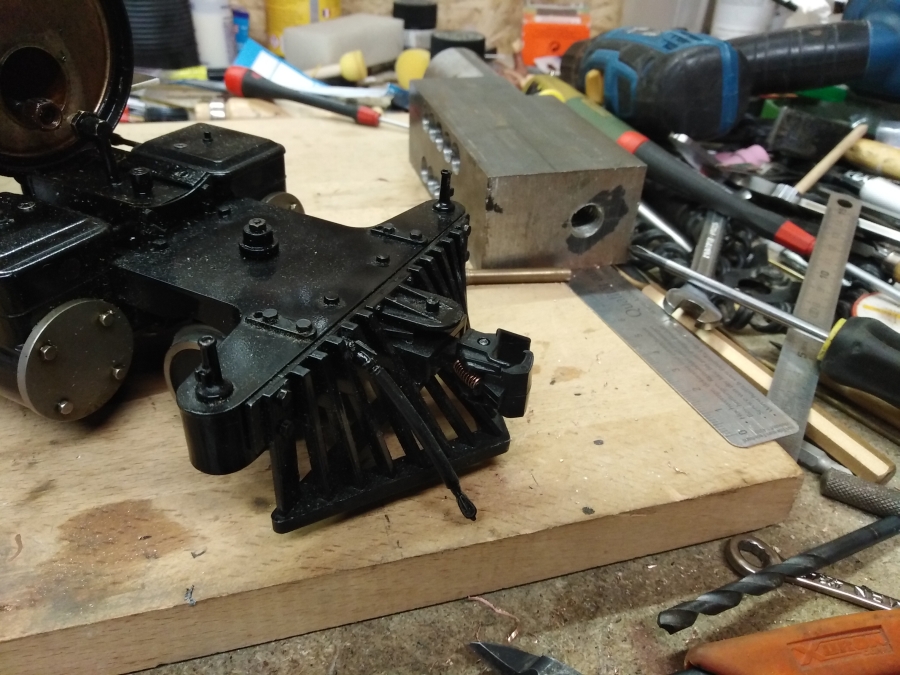

The fixed tender body does look much better now. Still missing were two new brass sheets to cover the front deck of the tender tank. Here you can see the tender brackets back in place at a right angle to the tender ends.

(https://waldbahner.de/wp-content/uploads/2019/01/IMG_20190105_215727.jpg)

As the inner parts of the original tender were no longer useful, I removed them and decided to install a wooden interior to the tender. I epoxied two blocks of 1/2″ plywood at the far ends into the brass shell.

(https://waldbahner.de/wp-content/uploads/2019/01/IMG_20190105_224436.jpg)

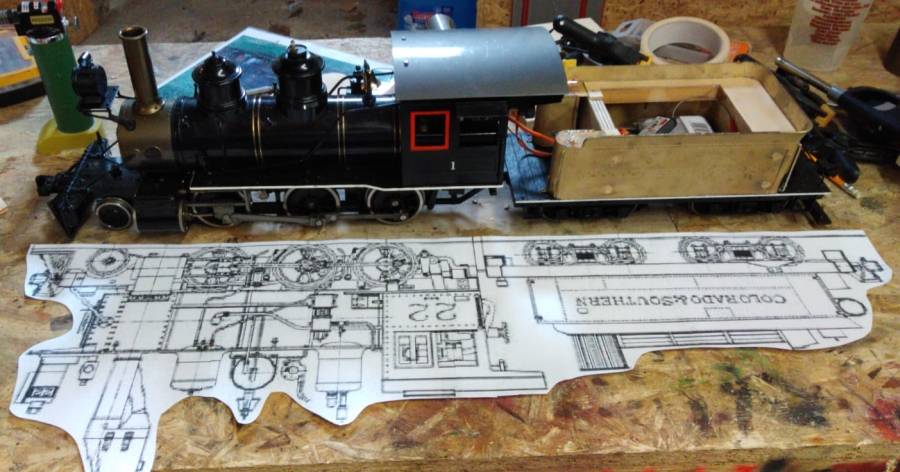

Later I added the top from 2mm plywood.The whole wooden part will be hidden by the coal bunker above, so I’m happy with this solution.

(https://waldbahner.de/wp-content/uploads/2019/01/IMG_20190108_164542.jpg)

At the rear end of the tender, I placed the air tank, which was originally located under the cab. I use several Colorado & Southern Moguls for inspiration on this project. There are still lots of details missing and paint off course.

(https://waldbahner.de/wp-content/uploads/2019/01/IMG_20190108_164547.jpg)

Now it’s time to get some more progress done on the loco. More on this will next week

Gerd