I am converting a Bachmann Climax to battery/radio operation and need a place to put batteries. I’ve seen pictures of wooden tank cars and thought that would be a good spot for batteries for my 1920-ish logging/mining layout. Here’s an example of the kind of car I am wanting (not my work, just inspiration):

I’ve just started attempting to build a similar car. This is my first scratchbuilt car (or much of anything really) so don’t be surprised if I screw up often. Advice is absolutely solicited as I’ve barely gotten started. I’m not very far so if I do need to throw something away it isn’t going to bother me too much (I kind of expect it, actually).

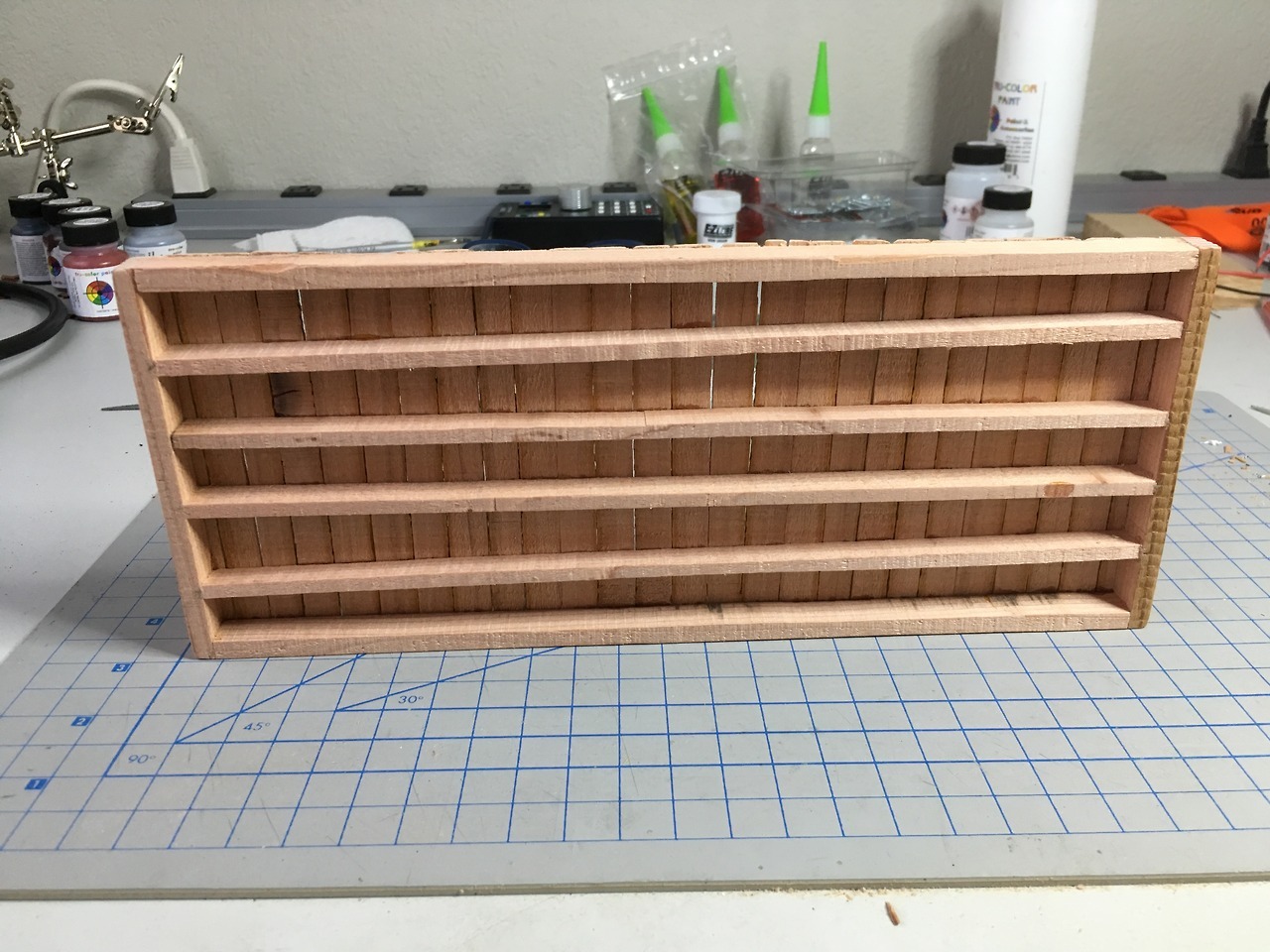

I’m using leftover redwood, used for the roadbed for my layout, ripped down to size on a bandsaw.

First step I took was to build a flatcar platform, vaguely following this scratchbuild tutorial. This is going to be at the head of a mine train with quite short cars, so I wanted this to be relatively short too. The flat car platform is 11" long by 4.5" wide, or 18.5’ by 7.5’ in scale. This pretty much matches the length of Bachmann log cars that I’ve been using. Here are a couple of pix:

I stressed the ends of the boards a bit.

Now I’m partway through buildling the tank. I’m using a 3" PVC pipe as the structural element. I cut a couple of holes for wires, a switch, and a recharge connector on top and bottom. Currently about halfway through gluing planks on the PVC. I have some concern that the 3" (inside) diameter is going to be too big, but the same kind of pipe at 2" (my only other easily available option, at least on my first search) seems pathetically small.

I’m enjoying a staycation for a little while so I’m going to see how far I can get on this, though that will depend on bits and pieces getting delivered.

Cheers!