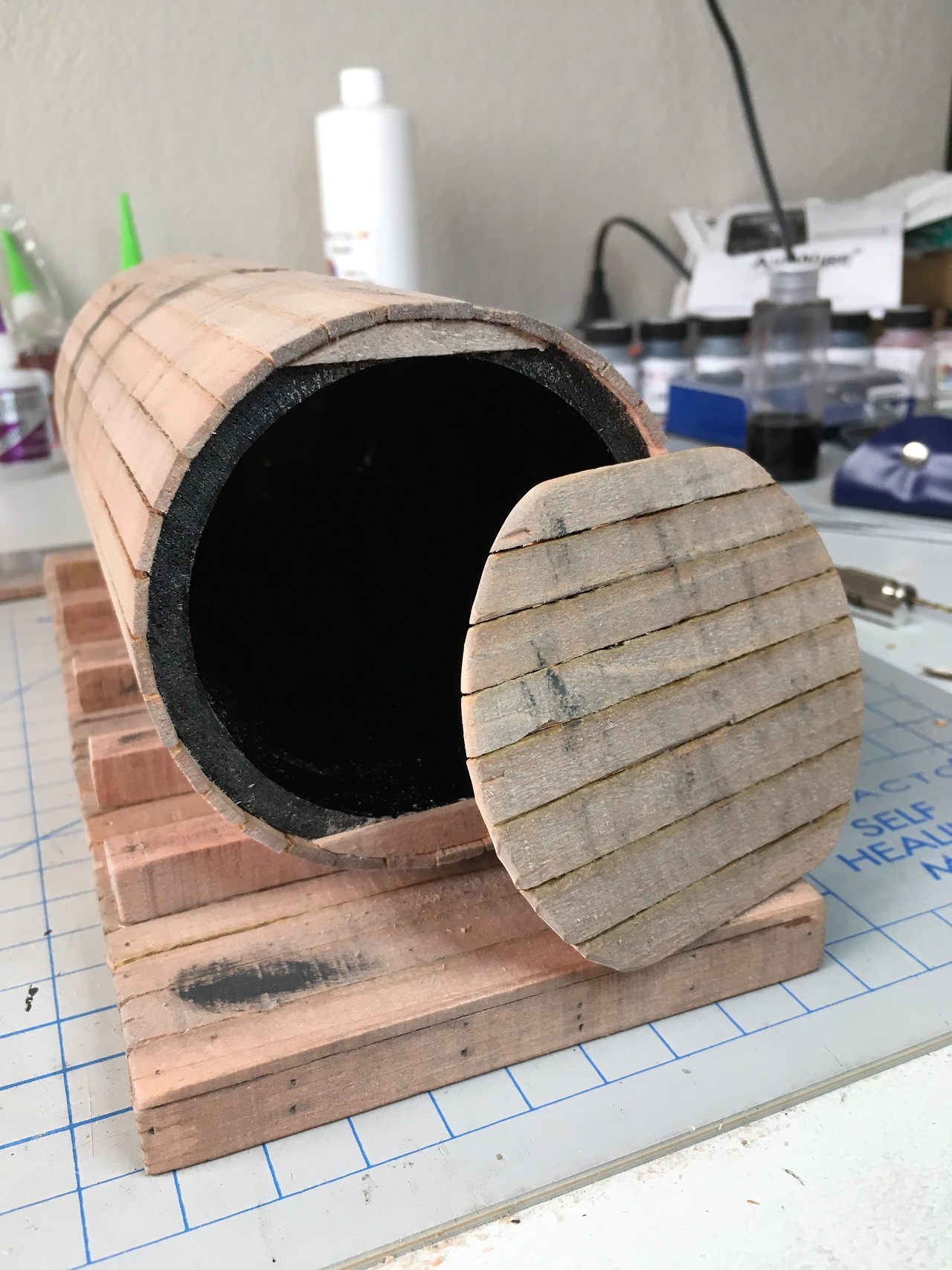

First round of weathering done: India ink wash/rub and “flat grimy black” dry brush. Will be working on straps and end caps, and the mysterious scheme to give access, next.

First round of weathering done: India ink wash/rub and “flat grimy black” dry brush. Will be working on straps and end caps, and the mysterious scheme to give access, next.

Me, too.

Use a long flexible spring to hold the ends to the tank. Have an option to move the spring to a hook to remove the end. Each end can be like that…

First thought off the top of me head …

Mine are friction fit.

Got the end caps done/weathered. The current thought about holding them in place is to use vertical beams glued to the end cap, the bottom ends held in place by a cross beam glued to the deck (not glued to each other). The original post in this topic shows the “inspiration” car and it has these same beams to hold the end cap in place (though I have no idea if they are removable).

A small bit of velcro inside the tank will hold the top. We’ll see how that works! Tomorrow’s task…

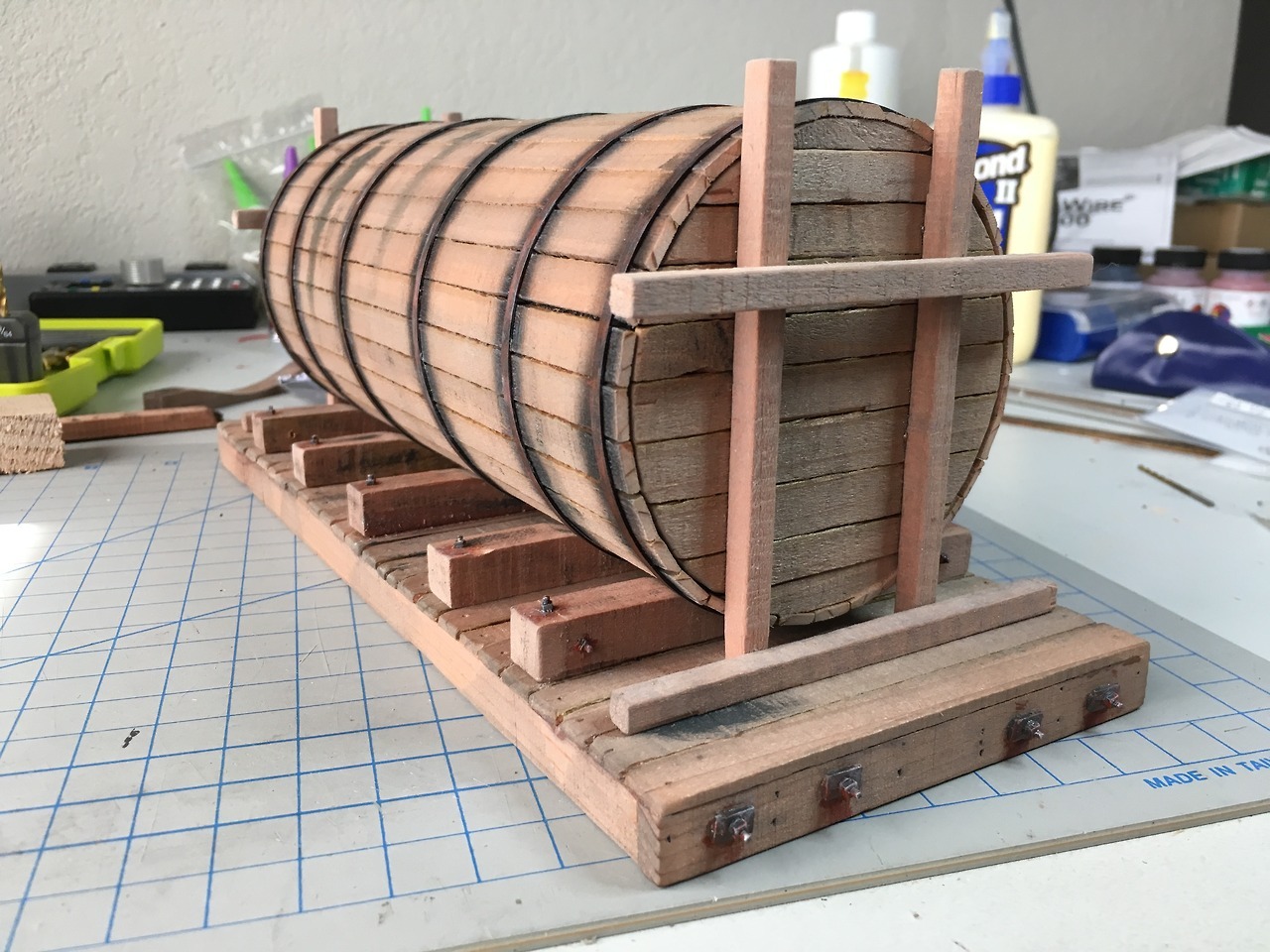

Bands and some bolt details. Next steps are weathering/rusting the bands and nearby tank, attach the tank, then build the end cap holders.

Awesome!

This is gonna be good!

Took a stab at weathering/rusting the straps and the bolt details. Attached the end cap braces, but do not have the internal velcro in yet (I want to wait for glue to set first).

To weather the straps, I put the tank on end on a “lazy susan” and used my airbrush to paint above/below each strap with “weathered black” followed by dry brushing of weathered rust, dust, and grime. Rust, dust and grime were used on the bolt details. I’m still trying to decide if I like the weathering. I may want to apply an overall grime spray or something to lessen the contrast between the strap areas and the rest of the tank. Any comments? I’m really very new at this weathering stuff…

There are 2 verticals attached to each end cap, a horizontal that is glued to the car base (not to the verticals) and another horizontal higher up glued to the verticals. This allows the end cap to pivot away from the tank. There will be a bit of velcro just inside the top of the tank to hold the top in place. Diagonal wires with a turnbuckle will attach from the higher up horizontals down to the farthest under-tank support. The top of the diagonal wires will just sit in a pinhole when the caps are on, no glue, so each time I open/close an end cap, some assembly will be required. Any suggestions for things to watch out for? I haven’t put the velcro in yet, so that’s still an open question. This won’t be sitting outside over night, in the weather, so that’s not a consideration. I was also considering using a simple friction latch (like for a small cabinet).

Still many details to add, some dry-brush weathering to do, etc. Then we get to the wiring, some kind of cap centered on the top to hide a switch and recharge plug, and the undercarriage.

Jim,

You are doing an EXCELLENT job. I like it a lot. ![]()

I tried using Velcro to hold the end caps closed, but they aren’t doing a very good job. They hold it closed, but not fully, and are a bit “squishy” (is that the technical term for it?).

I’m going to go to a spring idea inspired by John Caughey.

Here’s a short video showing how the current method is working/not working:

Graeme Price said:

This is an article from Garden Railways of Oct 2009 which may be of some help

Now that is a great how to article… Wink (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

I really like Don’t removable tanker top but what if you make an end of your tank removable and attach your necessary bits to a piece of wood that can be slipped in and out as needed?

Your tank is looking really good and the seams are disappearing.

How about making some small levers that can be turned to keep your end cap on similar to the ones we find to secure smokebox doors on Bachmann engines. 2 at the bottom can be fixed and one or 2 at the top swivel.

Todd:

The lever idea sounds pretty reasonable. I’ll think about that. Maybe that’s plan C :-).

John’s idea is to put a hook on the inside of the end cap that a spring would tug on. You can then pull it open some to disconnect the spring when you want to remove the end cap (a rare occurrence I hope!).

I bought some hooks and an assortment of sprints today so I’m going to experiment with that for now and see what happens.

Cheers and thanks for the suggestion!

That is looking great. Ill have to keep all these ideas for when I build one. Glad I waited.

I was thinking a metal plate in the end, and a cabinet magnet (or two) in the car.

For your first scratchbuild you are doing a great job! It looks good!!

Thanks for the encouragement folks!

OK, here’s the current list of closing-the-end-cap ideas:

Seems like one of those ought to work…

Since the top of the tank is all that needs to be fastened. Why not use the truss rods like in the original picture. Make them from brass rod and then use a lamp chain connector (clevis) for a turn buckle. You could then pop the rod out of the clevis and open the end. Your truss rod is gonna have to be part of the opening end anyway? Unless you are not going to make them.

I think a rare earth magnet would be too strong myself. You might never get it open. If you are gonna use a magnet use a weaker one.

Rooster: Interesting idea to use the turn buckle as the “catch” for this. I am indeed intending to put those rods in, but was going to use an off-the-shelf turnbuckle, which won’t do what you suggest afaik. I will admit that I’m a bit nervous about “popping” the rod out of the lamp chain connector. My fat fingers might end up doing some damage. However, it should go on the list of possibilities for sure.

I’ve played a bit with the rare earth magnet. It turns out (physics!) that the attraction is a function of both the strength of the magnet and the amount of iron being attracted. I have some .03" steel shim stock that, when cut into a narrow ribbon, keeps the attraction down to a very reasonable level. One nice thing is I can always add a bit more of the shim stock if the magnetic force isn’t enough, or weakens over time.

I’m pursuing the magnet scheme now (goop is setting) and will report back.

Thanks, David, for the suggestion!

If you can twist your end plate some, it’s easier to slide magnets apart than to pull them away from each other (or backing metals).

I rarely use my 1st idea either, so I don’t mind your becoming unsprung! (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-innocent.gif)

John

Oooh, the magnets are working well! I put the rare earth magnet on the end cap, and a very small strip of steel shim stock (.03" thick) on a piece of wood at the top, inside the tank. This gives me enough strength to hold it securely (including shaking it around) but I have single finger control to open it. Check the video for the demo. And no squishiness!