Steve said:

Bob,

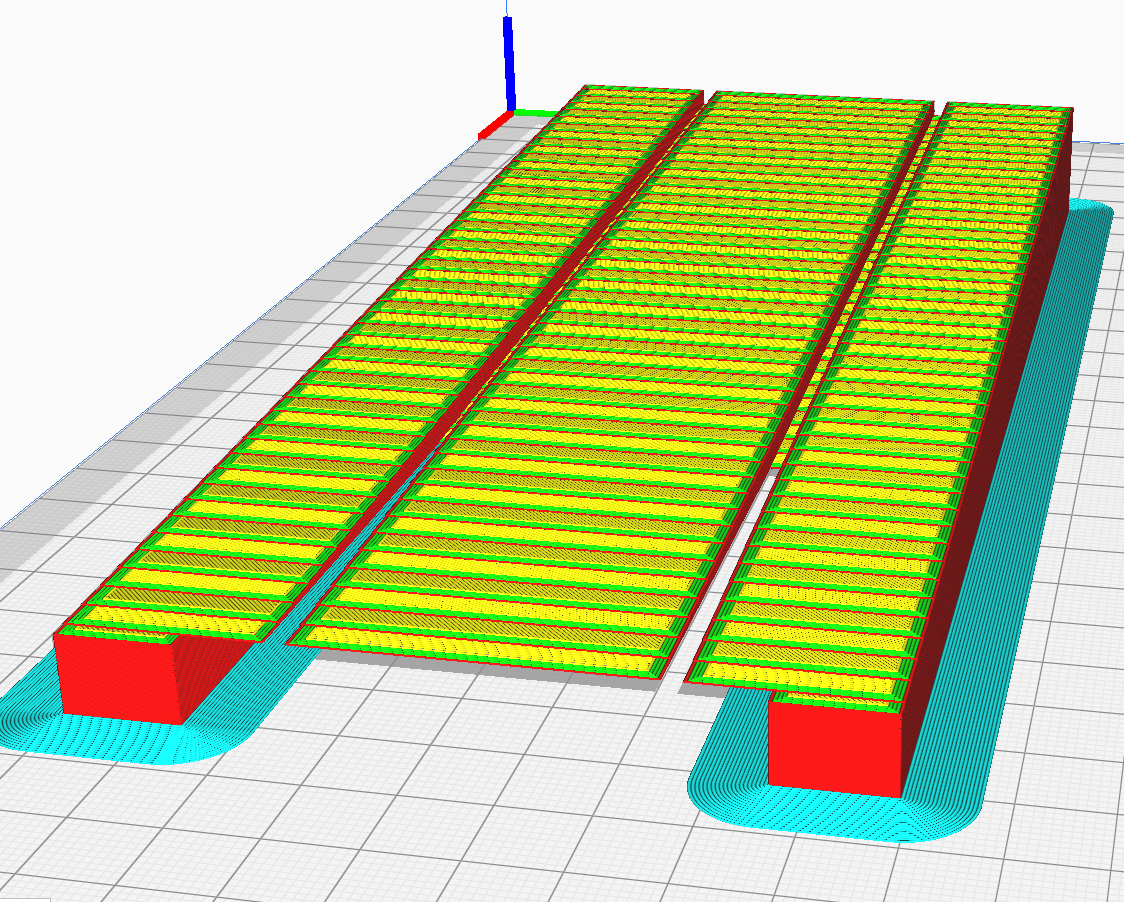

It wont … BUT - I’m thinking thru a carrier that uses aspects of the different carrier designs we have discussed.

What about a carrier with a short bottom section that popped off, allowing the carrier to be placed directly on top

of a stand in the shop with the above wheel rollers?

Now you have a solution where the loco/tender is stored/carried in this carrier, and can be used in the shop

as part of a roller test stand. Now it can be carried from shop to shelf to outdoor track without ever messing

with the drawbar or stressing the motorblock mounts.

I think you have a foam topped support bar in-between (and parallel to) the track along this short section

just short of touching the motor block assembly. When you remove the bottom section the weight of the

motor block is supported as it descends.

When you place the carrier on this shop stand the block lifts back up as the rollers engage the drive wheels.

I’m still thinking thru the details.

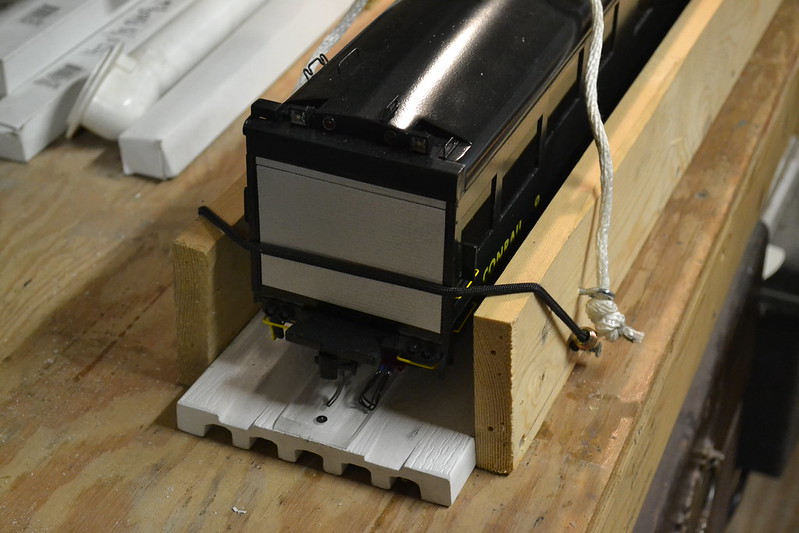

FYI: the stand in the above picture is in use with my DCC++EX project. Now I don’t have to haul the loco/tender

out to the train room to run tests of the system. So this solves 1/3 of my shop/train-room/outdoors dilemma.

Very cool. The best part of this hobby is that you only have to answer to your self.

.jpg)