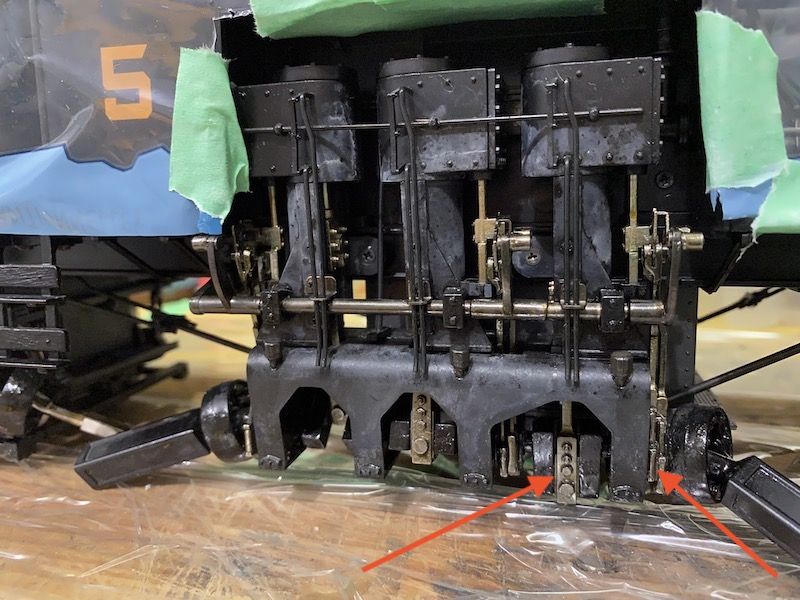

Time for an update, as I finally made a start on trying to remove thickened lubrication from my Bachmann Shay. I began by masking off the side and top of the loco with plastic sheeting taped to the running boards, with a cutout in the piston area. Since the drive line on the right side of the Shay starts with the motor in the front truck which drives the wheels and through bevel gears the whole drive train, I disconnected the sliding couplings at either side of the central piston/connecting rod/valve gear/crankshaft mechanism so it could be turned by hand. It was almost frozen solid at first but as I slowly turned it, it got easier and easier to turn. This was clearly the area presenting the most drag on the whole system.

My first attempt was with Dawn. Not knowing how much to dilute it (so little is used in a dishwashing situation) I decided to try a 10:1 water:Dawn mix to really hit it. Not sure if a more dilute solution would be more or less effective to try. I mixed the 1 part Dawn to 10 parts HOT water and put that in a spray bottle. I then sprayed the entire lower side of the Shay with liberal amounts of this hot soapy mix and turned the connecting rod/piston mechanism by hand. I then let it sit for about ½ hour and then went and hit it hard again before another ½ hour sit and the final hit with the soapy mix. Then I took another spray water with clean HOT water and sprayed the heck out if, getting rid of all the soapy mix. My impression was that the Dawn mix didn’t do a thing for it. After it had sat for some time it seemed to be just as frozen up as before.

My thoughts now are that the valve gear have a lot of surfaces that just slide past each other, as well as the connecting rod to crankshaft areas. When it seems freed up by rotation the gunk on these surfaces sheers and allows freer motion, but then after sitting, the gunk on the mating surfaces flows back together locking everything in place again. So how to get rid of ALL the gunk on touching surfaces without complete disassembly.

So next I tried isopropyl alcohol (70%) in a spray bottle. Again I liberally sprayed the mechanisms while turning by hand and almost immediately it seemed so much freer. I then sprayed with hot water to flush the areas clean and let it sit. To my disappointment, they stiffened up once more. I wasn’t getting the mating surfaces truly clean.

Today I gave the alcohol another go, but this time with a piece of spare brass tubing chucked into my electric drill, and the end inserted into one of the sliding couplings, I spun the crankshaft etc. mechanism continually while again spraying very liberally with isopropyl alcohol, hoping that it would make its way in between the mating surfaces eventually. Perhaps it did, but I am not sure it really dissolves the gunk. After less than an hour, the mechanism is already stiffening up. I would try penetrating oil if I thought it wouldn’t harm the plastics.

So I am still on the quest for a solution. At this point, over lunch, the “management” of our railroad asked if I had tried contacting Bachmann about this issue. It can’t be unique. So perhaps that is next.

Dave