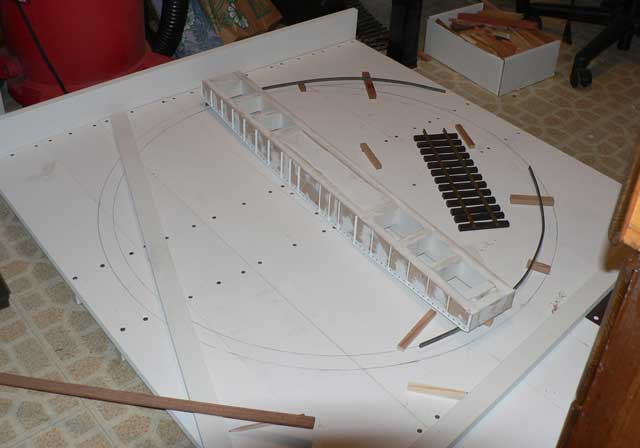

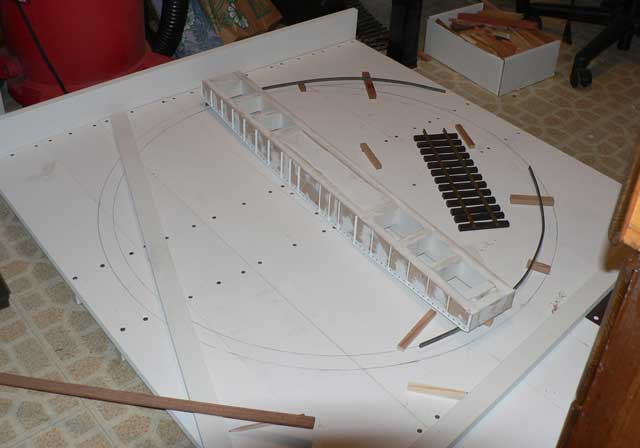

Matthew, Ah, that does look NICE! Well, my first stop was to take a single board and drill a hole where I wanted the main bearing. I’m not sure how you’ll fasten yours in place, but I suspect it will be something similar. I also built a little box under that part, thinking I might want some extra support for my bearing.

Then I started building out from that. I guess I could have framed it all first, but this made sense at the time. I later added two more strips underneath for reinforcement.

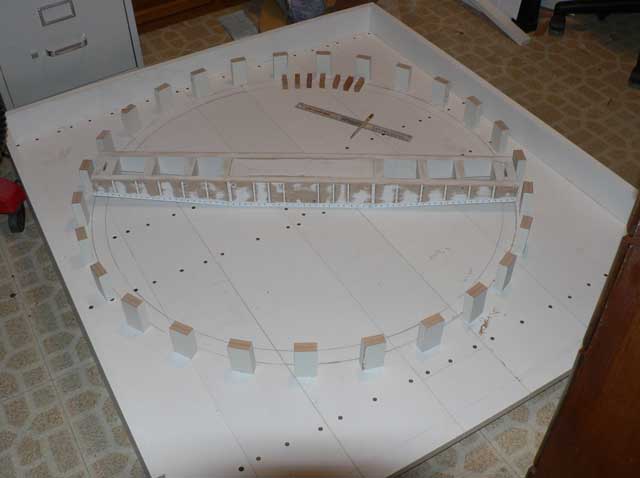

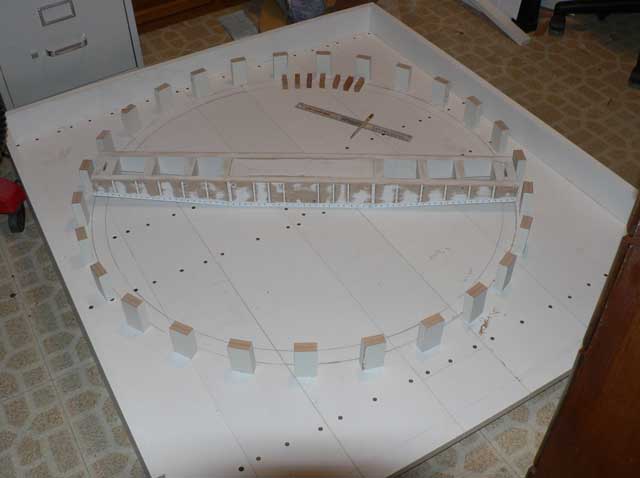

There are 2 lines on there - one for the wheel, so I’d know where my rail should be, the other for the wall. For this one, I just clamped a pencil in place at the CORNER of the turntable and drew a line as I rotated the turntable. I figured that this would be the inside of my pit wall, as it would be guaranteed to clear the bridge. I measured OUT 1/2" from this circle and drilled holes every x number of inches (I forget the value of X). This was for the support blocks. I first glued them in place, first making allowance for my wall material, making sure that the wall would not cross the line. (My wall material was about 1/8" thick). Then, I used those holes to put some decks screws from below - one in each block.

Finally, it was time to add the wall. I used Precision Products Perfic panels…mainly because I couldn’t think of anything else that would be easy. It was not as easy as I would have liked, as the panel material did not bend all that smoothly - I got some folds. I used 3" x 15" inch long sections and just used glue to attach them to the supports; 15" is the max width of the panels. I normally like to use glue and some mechanical fastening, but I felt that it would mar the surface too much. I wanted it to look like poured concrete.

I retraced the lines for my rail, then put down some ties and rail. I did end up putting some spacers under the ties to get the rail to the right height. I then capped the walls with 5/8" square stock and painted the whole mess with a textured paint from Rustoleum.

Well…hope that’s enough! Let me know if you have any questions. I’ll be looking forward to seeing your progress!