Oh, and Doc? Where do I get some Olde Frothingslosh Pale Stale Ale? (love the artwork there!)

Sorry Jim, those were custom made by a friend in Pittsburgh who has since passed. They were even approved by Rege Cordic, a long time radio personality on KDKA in Pittsburgh. It was on his show back in the early 60’s that the name of the beer was created. I believe the Fort Pitt Brewing Company produced it around Christmas time.

Someone else from the Pittsburgh area might expound on this.

Doc Watson

Hey, that’s ok. I don’t really need the beer, just thought the name was a hoot. Glad to hear a bit of the backstory…

I went a different direction and bashed a plastic canteen.

It’s an Aristo 20’ tank on the sloped back tender’s chassis. I wanted 4 wheel trucks under all that water. The hoses carry power to motor and lights/ speaker. The 2 vents are rotary switches …

On top is a monitor with a nozzle and the Swede as usual takes the 2 man nozzle alone…

Wood is scarce, so we protect our trestles and bridges.

I made the nozzles from sheet brass and wire. The hose is ‘Piping’ from a fabric store. Stained with coffee.

John

PS; when I do wooden cladding, I eye ball the angle and have had good results getting ‘close enough’ setting the table or band saws.

Wow John, I love that water tank car. Nicely done. All the little touches bashed from common materials are great. Very creative.

Thanks.

The hoses detach and there are caps (nuts with a domed bit of brass soldered on top) hanging on the tank and tender for stealthier times… (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-surprised.gif)

I made sure the connectors wouldn’t short when joining, I’ve seen enuf magic smoke.

John

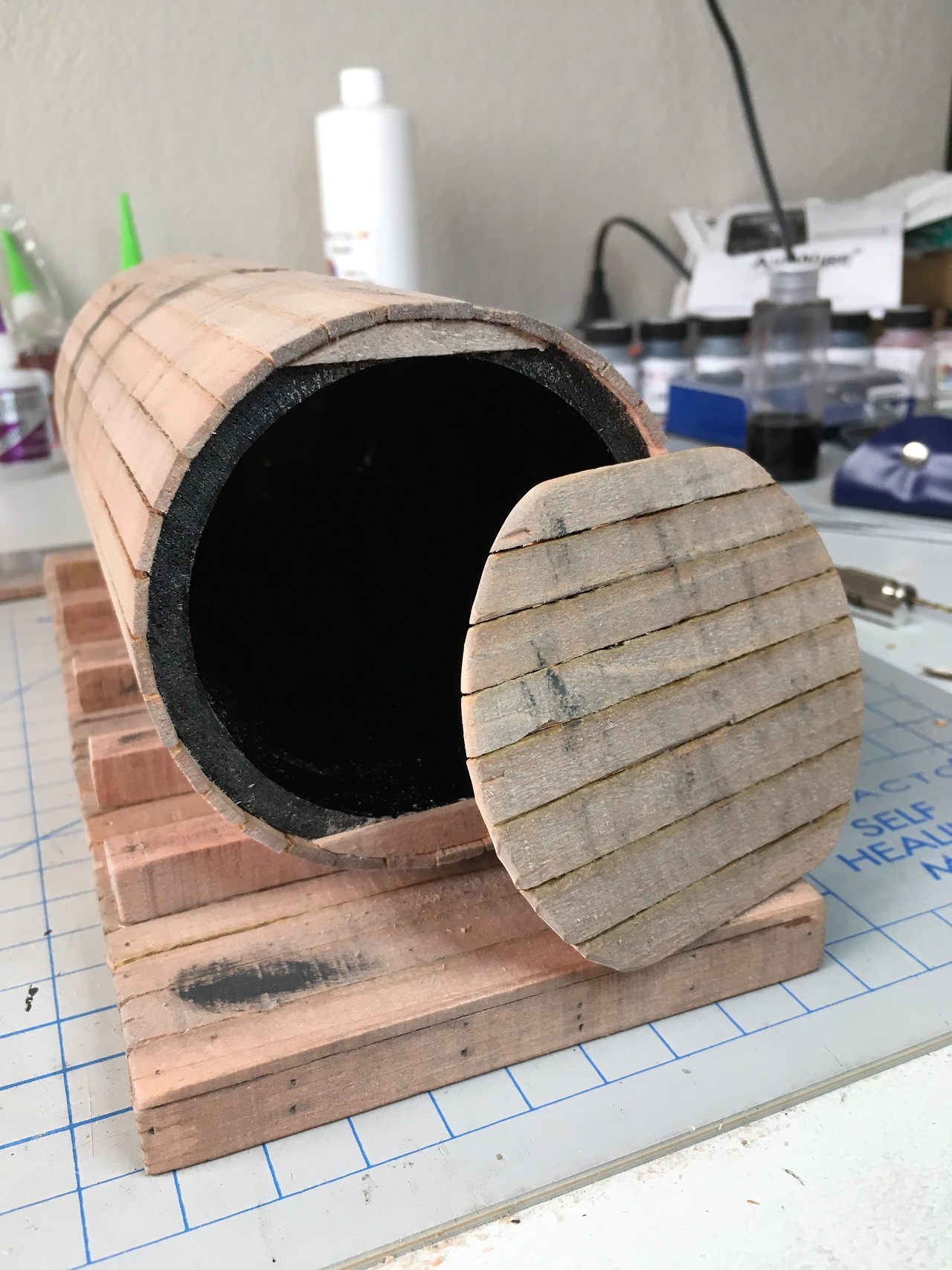

I’ve pushed ahead with the 3" PVC pipe plan to see how far I can take it. Here it is test fit onto the flat car platform:

So far I’m reasonably happy. We’ll see what jumps up to bite me…

Next steps: I need to weather this thing because I’m not going to leave it outside for nature to do that for me, so I’ll need to figure out how I want to get that wood looking reasonable. First thought is to use diluted India ink. Of course, I also need to build the end caps and how they are held in/come out on demand. I have a plan in mind… we’ll see if it works

After that there’s a ton of details to add, underbody stuff to build, etc.

Cheers!

Where’s the “like” button when you need one, Great start, and I like the “tar” idea with using the black pipe.

This is an article from Garden Railways of Oct 2009 which may be of some help

Second half of the article

Thanks Graeme.

Shoe laces make nice covering over wire… Hose !(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

I also used super flexible wire, for the connecting wires. I found it in an Airplane R/C shop. Silicone I think.

John

Mike Wlez said:

Where’s the “like” button when you need one, Great start, and I like the “tar” idea with using the black pipe.

You can borrow the one I use…

Thanks Joe

First round of weathering done: India ink wash/rub and “flat grimy black” dry brush. Will be working on straps and end caps, and the mysterious scheme to give access, next.

Me, too.

Use a long flexible spring to hold the ends to the tank. Have an option to move the spring to a hook to remove the end. Each end can be like that…

First thought off the top of me head …

Mine are friction fit.

Got the end caps done/weathered. The current thought about holding them in place is to use vertical beams glued to the end cap, the bottom ends held in place by a cross beam glued to the deck (not glued to each other). The original post in this topic shows the “inspiration” car and it has these same beams to hold the end cap in place (though I have no idea if they are removable).

A small bit of velcro inside the tank will hold the top. We’ll see how that works! Tomorrow’s task…

Bands and some bolt details. Next steps are weathering/rusting the bands and nearby tank, attach the tank, then build the end cap holders.